Internal recycle booster

A booster, internal circulation technology, applied in clutches, mechanical equipment, etc., can solve the problems of return spring corrosion, dust cover failure, sealing ring damage, etc., and achieve the effect of prolonging service life and reducing failure frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

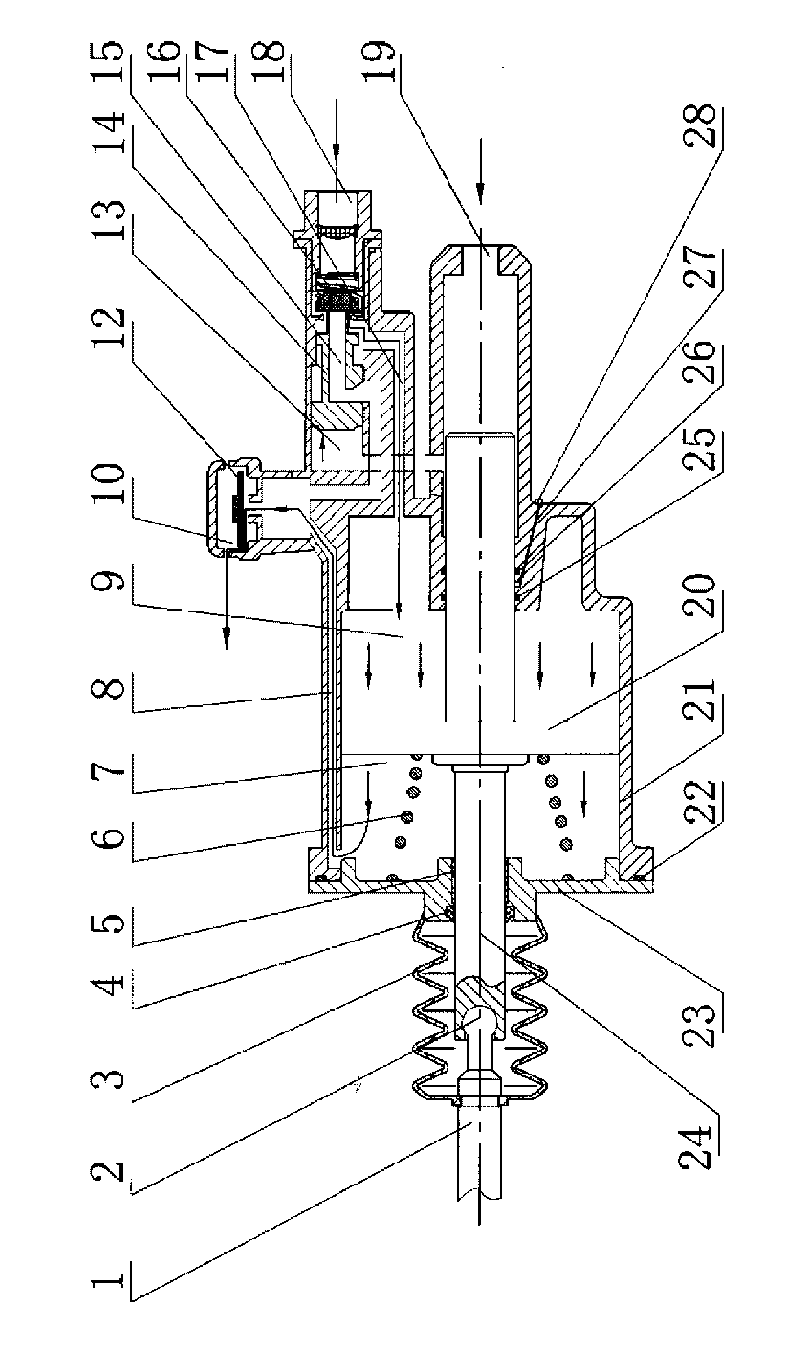

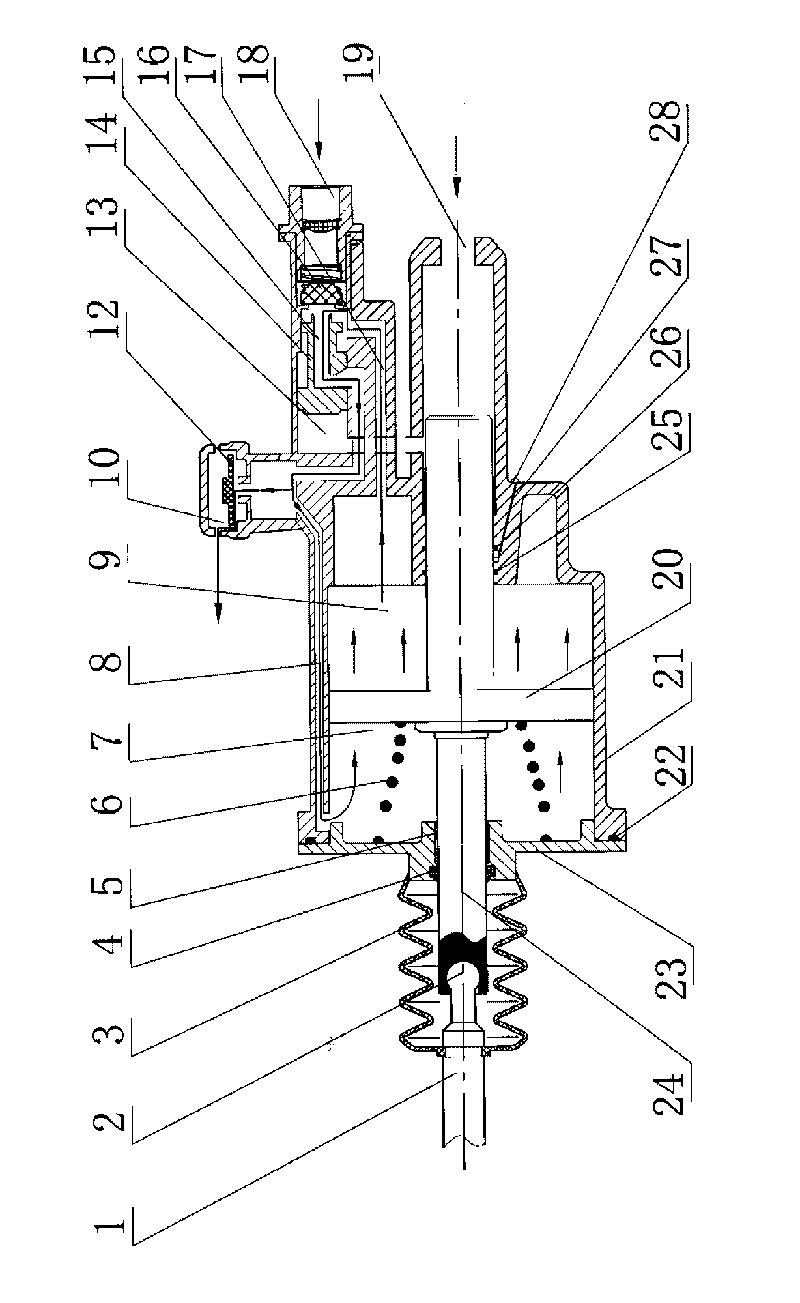

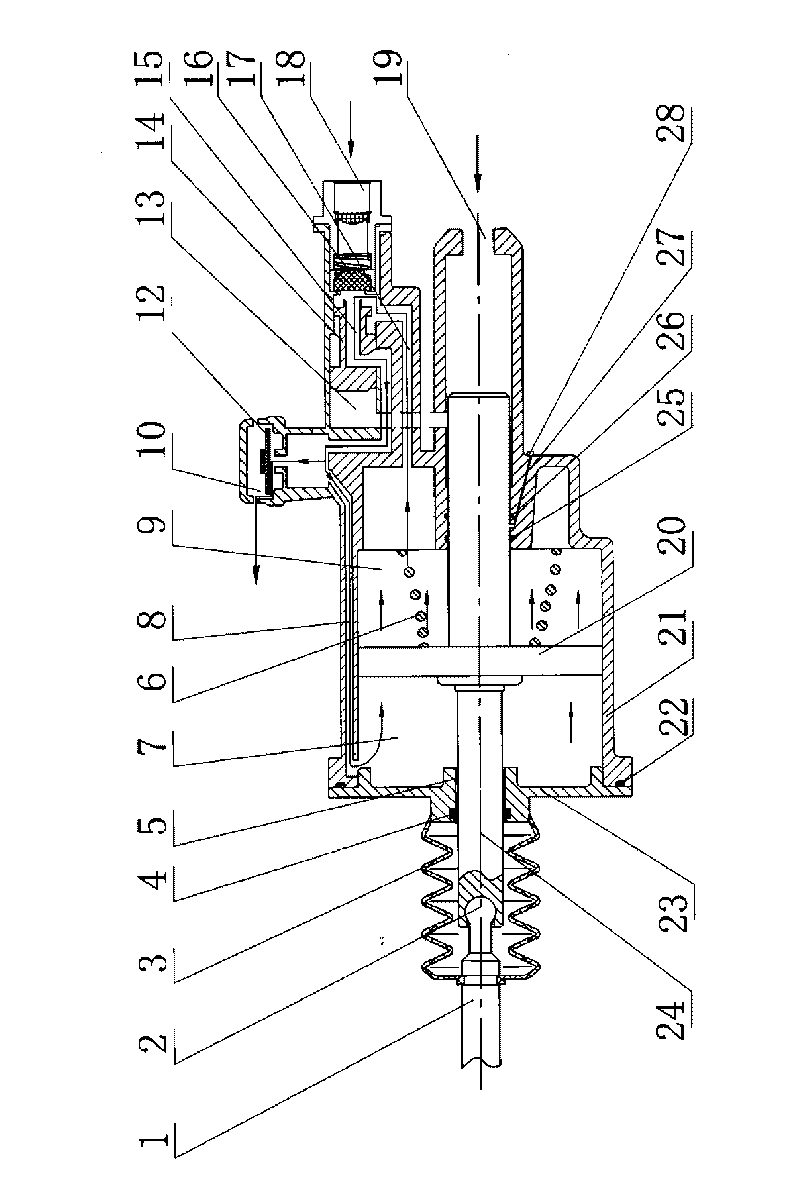

[0011] Referring to the accompanying drawings, this internal circulation booster includes a housing 21, an end cover 23, a booster piston 20, a return spring 6 and a piston rod 24, the booster piston 20 is placed in the housing 21, and the booster piston 20 drives the cylinder The body 21 is divided into a front chamber 7 and a rear chamber 9. The return spring 6 is installed in the housing 21 and is in contact with the booster piston 20. The piston rod 24 is connected with the push rod 1 through the cardan shaft 2. The cardan shaft is a ball joint; the housing 21 is provided with an air inlet 18, an air outlet 10 and an oil inlet 19, and the air inlet 18 communicates with the air outlet 10 and the rear chamber 9 respectively, so that The end cover 23 and the front cavity 7 form a fully enclosed cavity, and the end cover 23 and the front cavity housing are sealed with an O-shaped sealing ring 22, which can effectively prevent external moisture and impurities from entering the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com