Emulsified liquid supply device

A technology of emulsion and emulsion pump, which is applied to components of pumping devices for elastic fluids, liquid displacement machinery, liquid fuel engines, etc., and can solve the problem of reducing the working stability of hydraulic systems and affecting the use of emulsion pumps Performance, emulsion pump sealing parts aging and other issues, to achieve the effect of saving power resources, ensuring normal operation, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

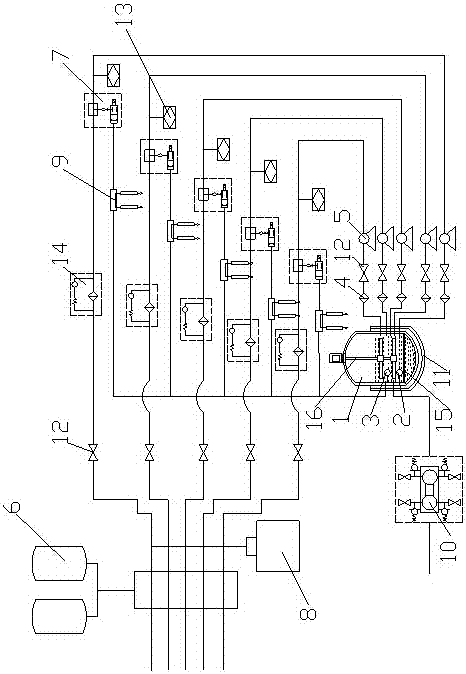

[0020] like figure 1 As shown, an emulsion liquid supply device proposed by the present invention includes: multiple sets of emulsion liquid supply components, working surface liquid return components, heat preservation components and controllers;

[0021] The emulsion liquid delivery component includes an emulsion tank 1, a liquid suction filter 4, an emulsion pump 5, an accumulator group 6, a mechanical unloading valve 7 and a pressure sensor 8. The emulsion tank 1 is provided with a liquid level sensor 2, a liquid The temperature sensor 3 and the stirring assembly 16, the emulsion tank 1, the liquid suction filter 4, the emulsion pump 5, the accumulator group 6 and the support of the working surface are connected through the liquid delivery pipeline in sequence; the mechanical unloading valve 7 and the pressure sensor 8 are all set On the liquid delivery pipeline, the mechanical unloading valve 7 is also connected with a liquid return pipeline, and the liquid outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com