Paddle wheel for paddle wheel ship

A technology of paddle steamers and paddle wheels, applied in the field of paddle steamers, can solve the problems of wasting kinetic energy, wasting a small amount of kinetic energy, and a large proportion of useless work, and achieve the effects of improving propulsion efficiency, avoiding energy waste, and reducing useless work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

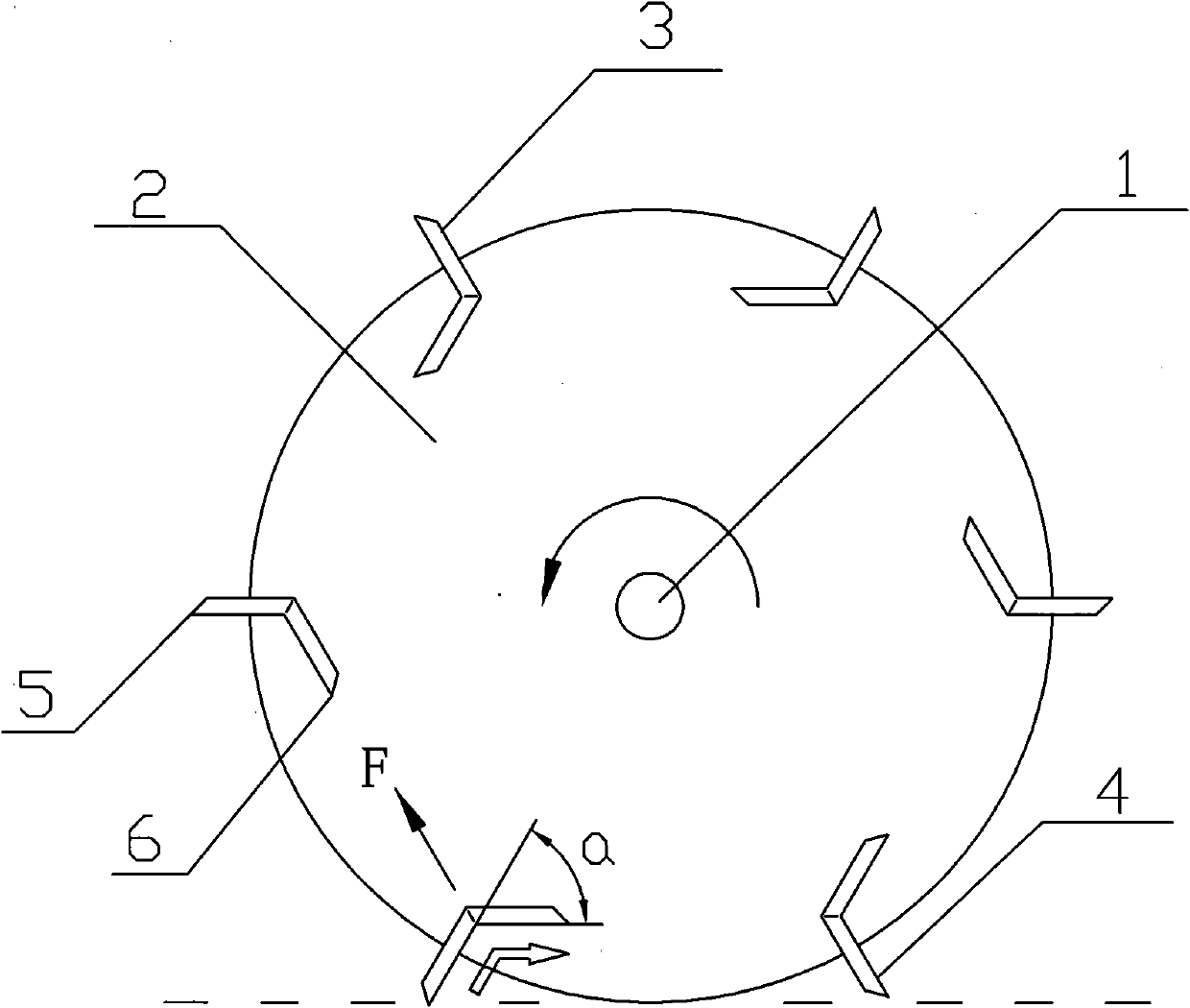

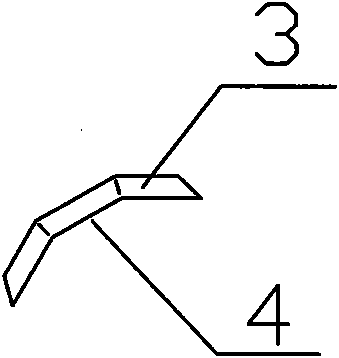

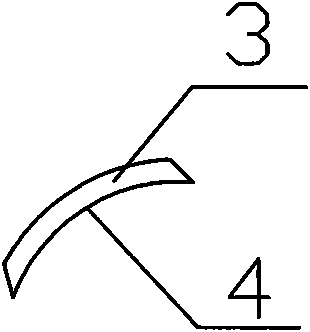

[0015] Such as figure 1 As shown, the paddle wheel used for paddle steamers according to the present invention consists of a wheel shaft 1, a wheel hub 2 installed around the wheel shaft 1, and six blades 3 arranged radially and evenly on the outer edge of the wheel hub 2. The water-repelling surface 4 of the paddle 3 is composed of two interconnected planes, the water-repelling surface 4 of the paddle 3 is deflected from the outer edge 5 to the inner edge 6 to the direction of rotation of the paddle wheel, and the deflection angle a is 60° degree; the outer edge 5 of the water-repelling surface 4 and the end surface of the paddle 3, and the inner edge 6 and the end surface of the paddle 3 are all acute angles. Such as figure 2 As shown, the water repelling surface 4 of the paddle 3 may also be composed of three planes. Such as image 3 As shown, the water-repelling surface 4 of the paddle 3 can also be an arc surface. Such as Figure 4 As shown, the water-repelling surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com