Graphene component

A component and graphene technology, which is applied in the direction of bearing components, components with teeth, portable lifting devices, etc., can solve the problems of large load, high energy consumption, and large specificity of polished rods, and achieve low fluid friction and reduce failure Effect of Frequency, Boost and Pump Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

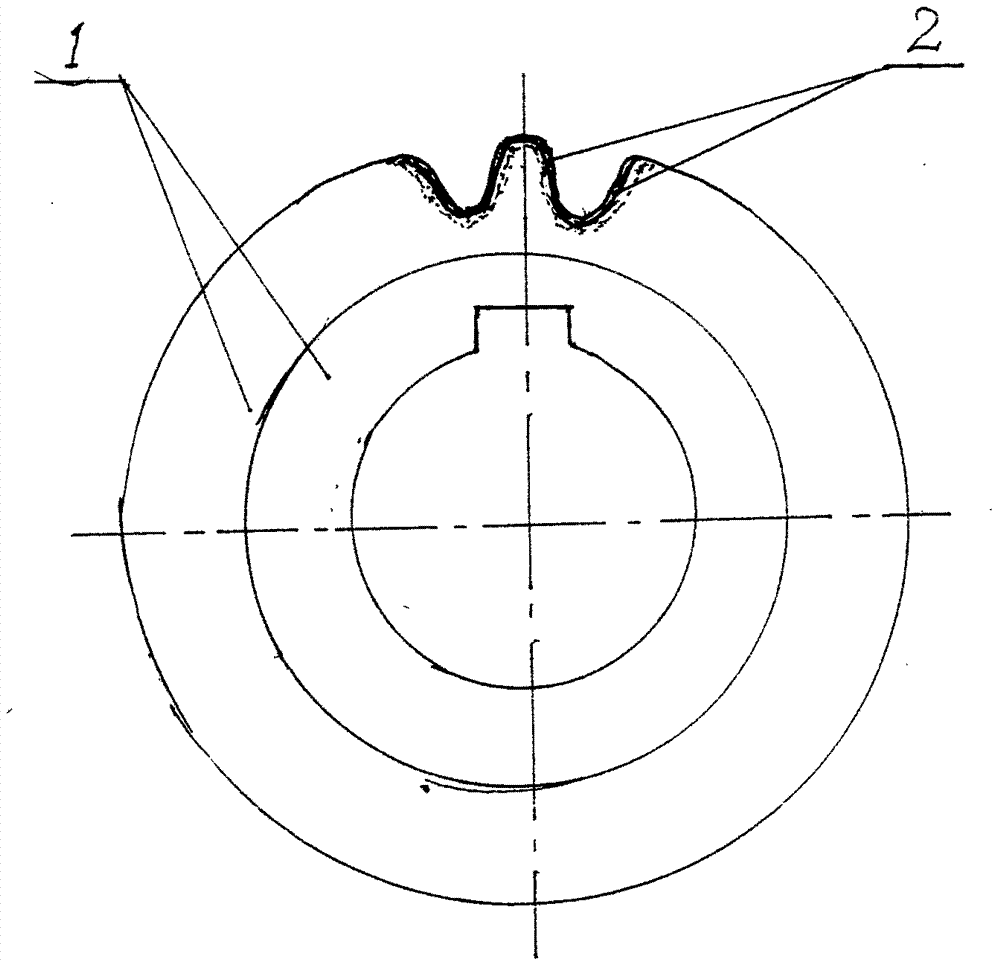

[0031] (5) specific implementation method: a kind of graphene parts, it contains parts (1), and parts (1) contains graphene (2).

[0032] Parts (1) contain more than 0.3% graphene (2) and the rest are one or more than one of metal, tree finger, synthetic material, natural material, plastic, glass, fiber, polymer material.

[0033] Graphene (2) is distributed uniformly or non-uniformly in the component (1).

[0034] The graphene (2) is distributed on the component (1) in one or more combinations of plating, coating, infiltration, embedded layer, embedded layer, ring layer, mixed layer, and composite layer. A combination of one or more of the surface layer and the surface layer and the surface layer.

[0035] Parts (1) containing graphene (2) are moving parts, sliding parts, rotating parts, rolling parts, functional parts, temperature-resistant parts, heat-conducting parts, display screens, parts, components, assembly parts, complete sets, complete sets Fittings, etc.

example 1

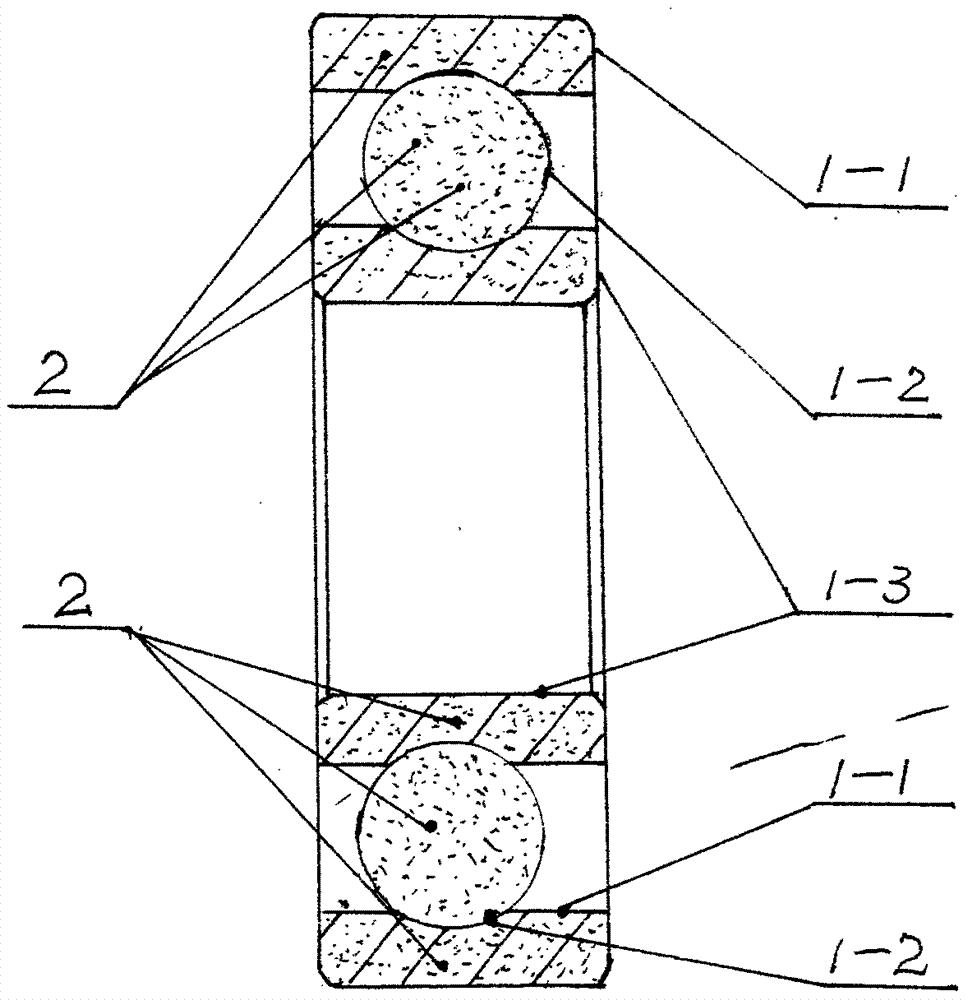

[0036] Example 1: According to the performance of the bearing steel, manufacture bearings containing graphene, select the composite material of graphene and aluminum alloy, make the graphene evenly distributed in the main material, and purchase the one that can meet the requirements between 2.5% and 4.5% performance, then precision casting, the tolerance is controlled within the allowable range of the bearing, and finally assembled into a bearing, the weight is 75% lighter, the mechanical performance is nearly twice that of bearing steel, and the application field is very wide.

example 2

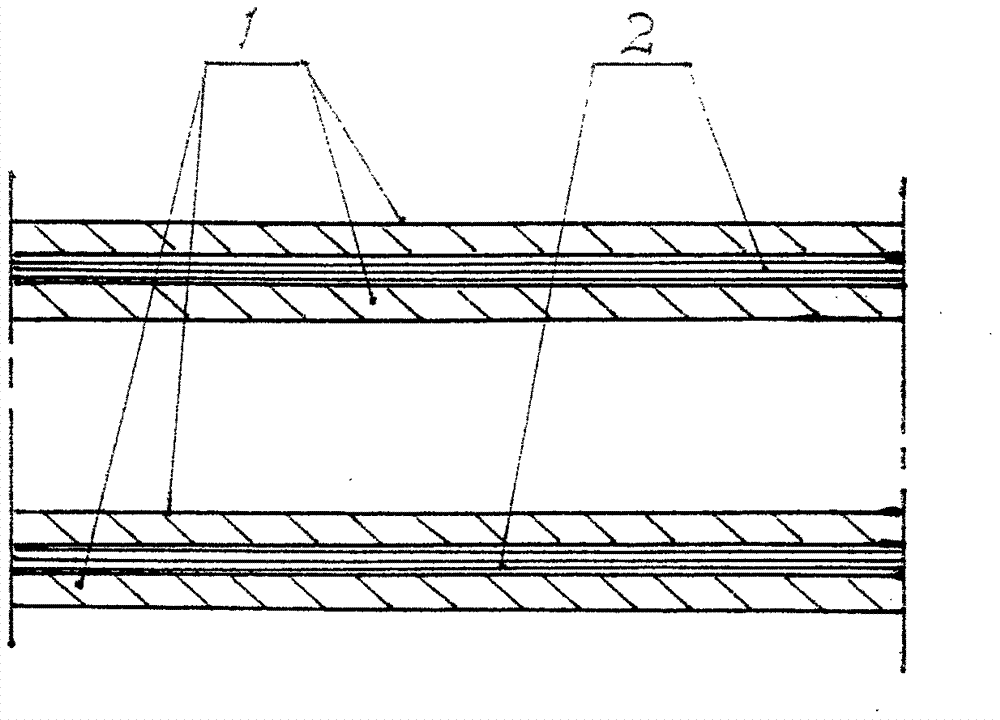

[0037] Example 2: the macromolecular base containing 0.2~5% graphene is placed in the container, with carbon fiber, glass fiber, aramid fiber braided into cylindrical loose body, through the container that is placed in macromolecular graphene to weave The cylindrical loose is dipped into a solid body, and drawn into hollow sucker rods, oil pipes and drill pipes within 5,000 meters for screw pumps, coiled tubing, continuous drill pipes, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com