Fiber-reinforced composite coiled sucker rod and production apparatus and method thereof

A composite material and fiber-reinforced technology, applied to chemical instruments and methods, drill pipes, drilling equipment, etc., can solve the problems of increasing axial tensile modulus, high cost, and inability to choose, so as to increase radial strength and Axial compressive strength, easy operation and transportation, and the effect of ensuring continuous stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

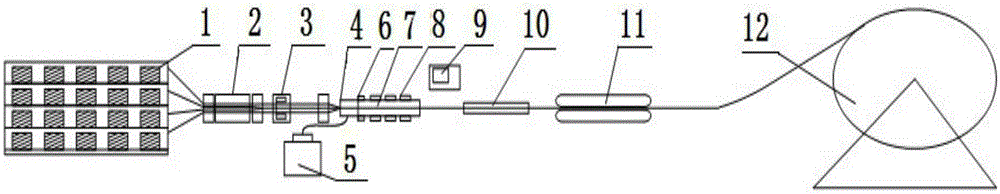

[0035] In addition, the present invention also improves a preparation method of the above-mentioned fiber-reinforced composite material continuous sucker rod, comprising the following steps:

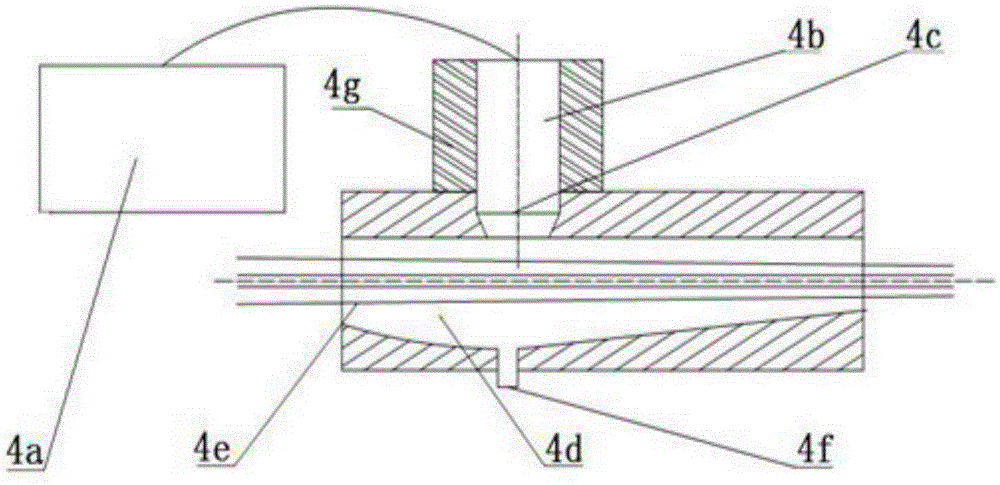

[0036] 1) Lead out multiple bundles of carbon fibers and H-grade glass fibers from the wire unwinding frame 1, and pass through the injection mold 4 under the traction of the traction device 11, and the injection mold 4 is prefilled with the epoxy resin matrix glue injected by the injection machine 5;

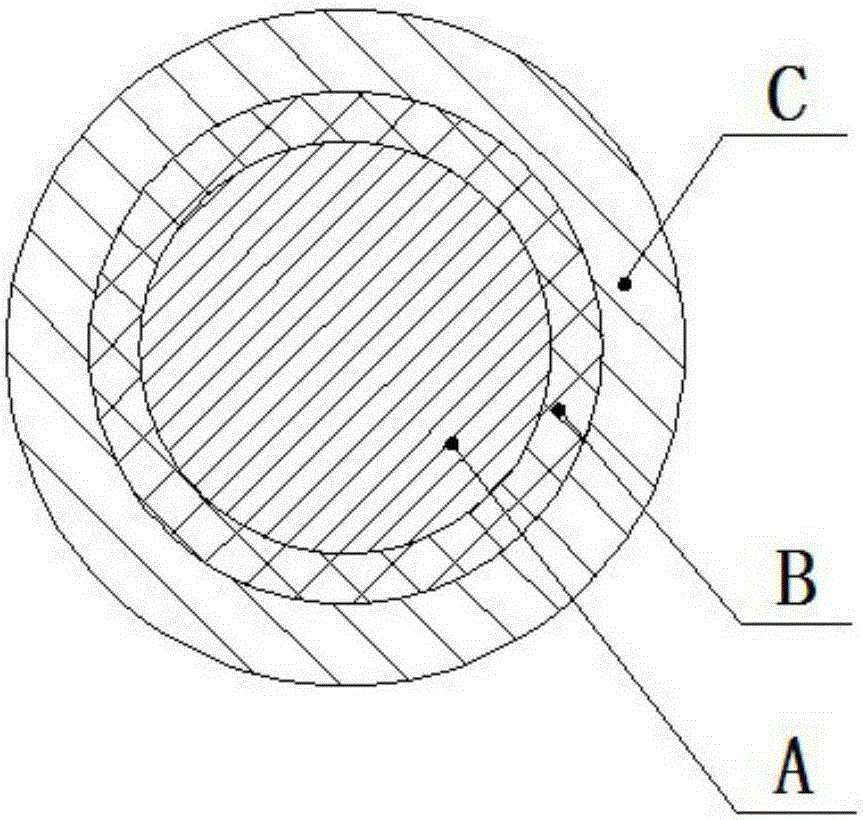

[0037] 2) Between the inner unidirectional carbon fiber A of the inner layer and the outer glass fiber layer C of the outer layer, use a winding machine or a weaving machine 3 to wind or weave an intermediate glass fiber layer B, and the thickness of the intermediate glass fiber layer B is 1 ~2mm, the winding or weaving is bidirectional winding or weaving, and the crossing angle of the two directions of winding or weaving is 15~85°; the winding or weaving middle glass fiber layer B enters ...

Embodiment 1

[0040] First, through the control operation of the control device 9, 170 T300-12K carbon fiber filaments and 130 H-grade glass fibers with a linear density of 24TEX are respectively entered into the pretreatment heating furnace 2 through the wire discharging holes of the wire unwinding frame 1. The furnace temperature is At 120°C, the traction speed is 0.15m / min, 170 T300-12K carbon fibers after heat treatment are bundled into a perfect circle with a diameter of 12mm, and pass through the core hole between the two winding machines;

[0041] The rotation directions of the two winding machines are opposite (facing the moving direction of the carbon fiber bundle, the first winding machine rotates clockwise, and the second winding machine rotates counterclockwise). Grade glass fiber, 8 H-grade glass fibers are drawn out in turn, and pass through the wire hole in the middle of the winding machine to form a 4mm wide glass fiber tape. The 4mm wide glass fiber tape is evenly wound on a...

Embodiment 2

[0046] According to implementation 1, change the number of unidirectional H-grade glass fibers in the outer layer to produce fiber-reinforced composite continuous sucker rods with different diameters: change the number of H-grade glass fibers with a linear density of 24TEX to 210, and 170 T300 -12K carbon fiber filaments enter the surface treatment furnace through the filament holes of the unwinding rack 1 respectively. The rest is the same to the heat treatment operation.

[0047] After heat treatment, 210 H-grade glass fibers with a linear density of 24TEX were bundled into 15 bundles of 14 fibers, which were evenly distributed on the outside of the circular carbon fiber bundles wrapped with two layers of glass fibers, and bundled together into a diameter of 22.2 The perfect circle of mm enters the injection mold 4, and the injection mold 4 is filled with the epoxy resin glue injected by the injection machine 5;

[0048] The fully impregnated fiber bundle enters a perfect c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com