An optimization method for shale gas horizontal well perforation cluster distances

An optimization method and technology for shale gas wells, applied in the directions of instrumentation, data processing application, prediction, etc., can solve the problems of increasing the fracture pressure of the reservoir, not proposing the design cluster spacing, etc., and achieve the effect of improving production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0074] Such as Figure 8 Shown, the inventive method is specifically as follows:

[0075] (1) Horizontal well fracture pressure prediction method considering stress interference

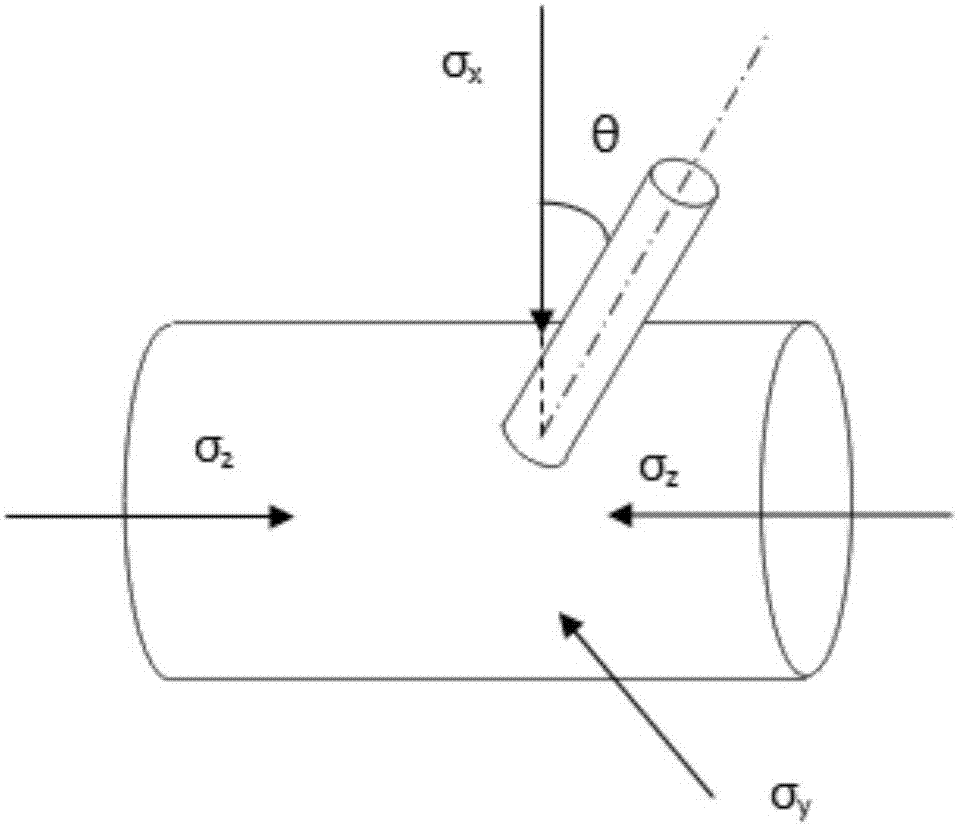

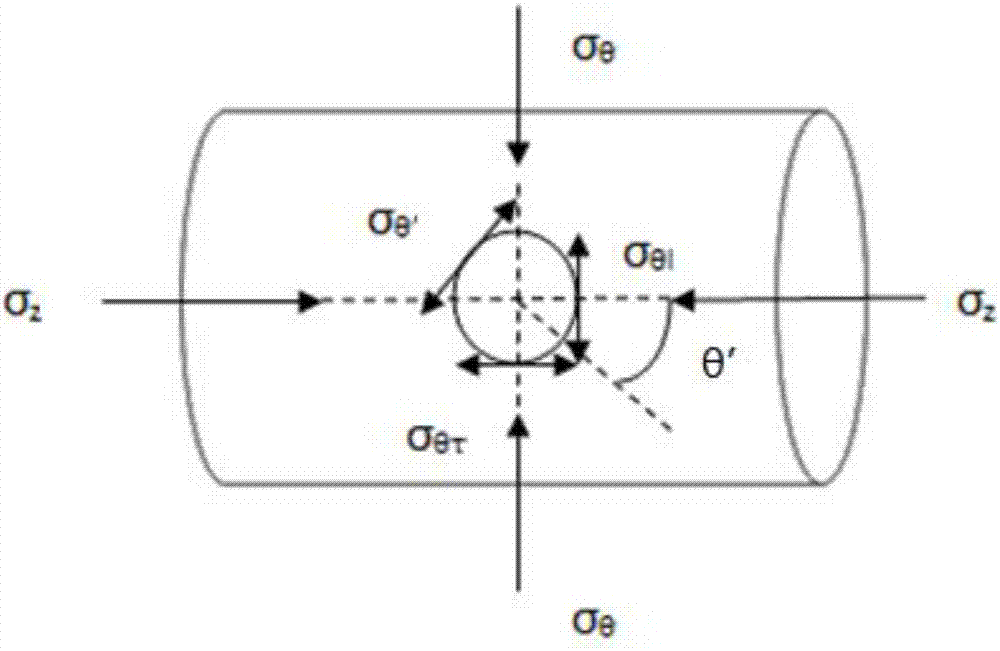

[0076] 1.1 Analysis of perforated wellbore geometric model

[0077] Assuming that there is good communication between the wellbore and the perforated hole, that the wellbore and the perforated channel have the same fluid pressure, and that there is a microannulus between the cement sheath and the perforated hole before the fracture initiates, the perforated wellbore is considered to be two holes of different sizes Perpendicular intersecting, perforated wellbore geometry and its stress redistribution as Picture 1-1 and Figure 1-2 shown. Among them, σ z is the wellbore axial stress, σ θ is the wellbore tangential stress, σ θ′ is the perforation tangential stress, σ θl is the concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com