High-performance TC11 tube and preparation thereof

A TC11, high-performance technology, applied in the field of metal materials, can solve the problems of difficult to achieve the common improvement of strong plasticity of materials, difficult to ensure dimensional accuracy and type tolerance, secondary annealing and pickling or alkali cleaning, etc., to achieve high strength. , performance improvement, the effect of reducing the frequency of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

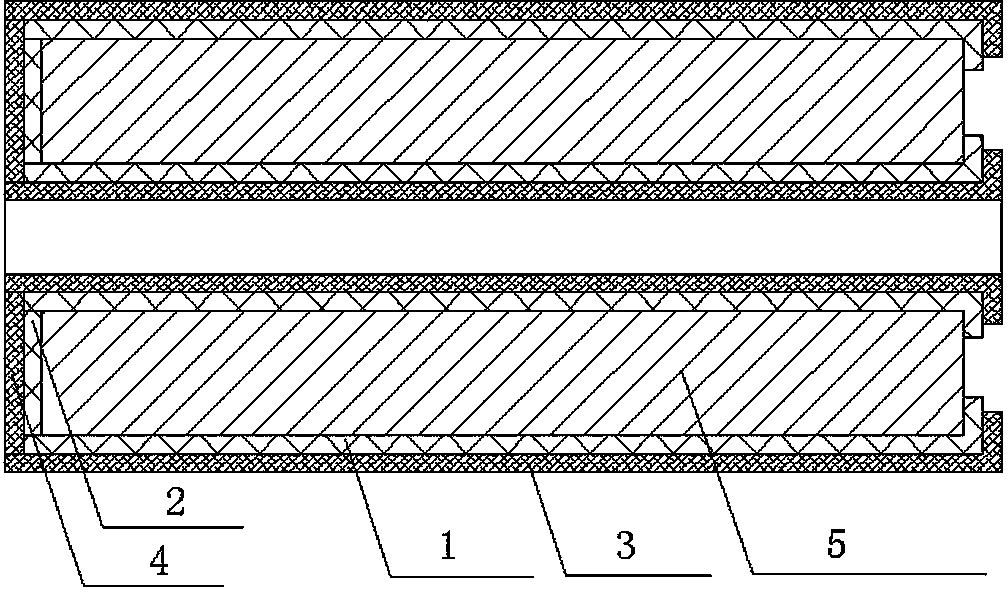

Image

Examples

Embodiment example

[0037] 1. Ingot preparation:

[0038]Use grade 1 sponge titanium and added alloy (aluminum vanadium alloy, aluminum molybdenum alloy, zirconium chips) ingredients and electrode blocks to press, and electrode blocks are assembled and welded to prepare electrodes, and then vacuum consumable arc melting is carried out twice to prepare Φ600mm TC11 titanium alloy castings Ingot, the chemical composition is: Al—6.46%, Mo—3.1%, Zr—1.78%, Si—0.297, Fe—0.095%, C—0.011%, N—0.061%, H—0.001%, O—0.13%, The balance is Ti, other impurity elements <0.10% alone, and the sum <0.40%. The phase transition point was determined to be 1010°C by heating metallographic method.

[0039] 2. Billet forging

[0040] The Φ600mm TC11 titanium alloy ingot has been forged for a total of 6 fires, three times of forging above the phase transition point, a total of six upsetting and seven drawing forgings to Φ365mm, and the total forging ratio is Y=7.59. Below the phase transformation point, three times of fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com