Nano-material associated clean fracturing fluid system and application thereof in oil and gas fields

A clean fracturing fluid and nano-material technology, applied in nano-material association clean fracturing fluid system and its application in oil and gas fields, to achieve broad market prospects and improved temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

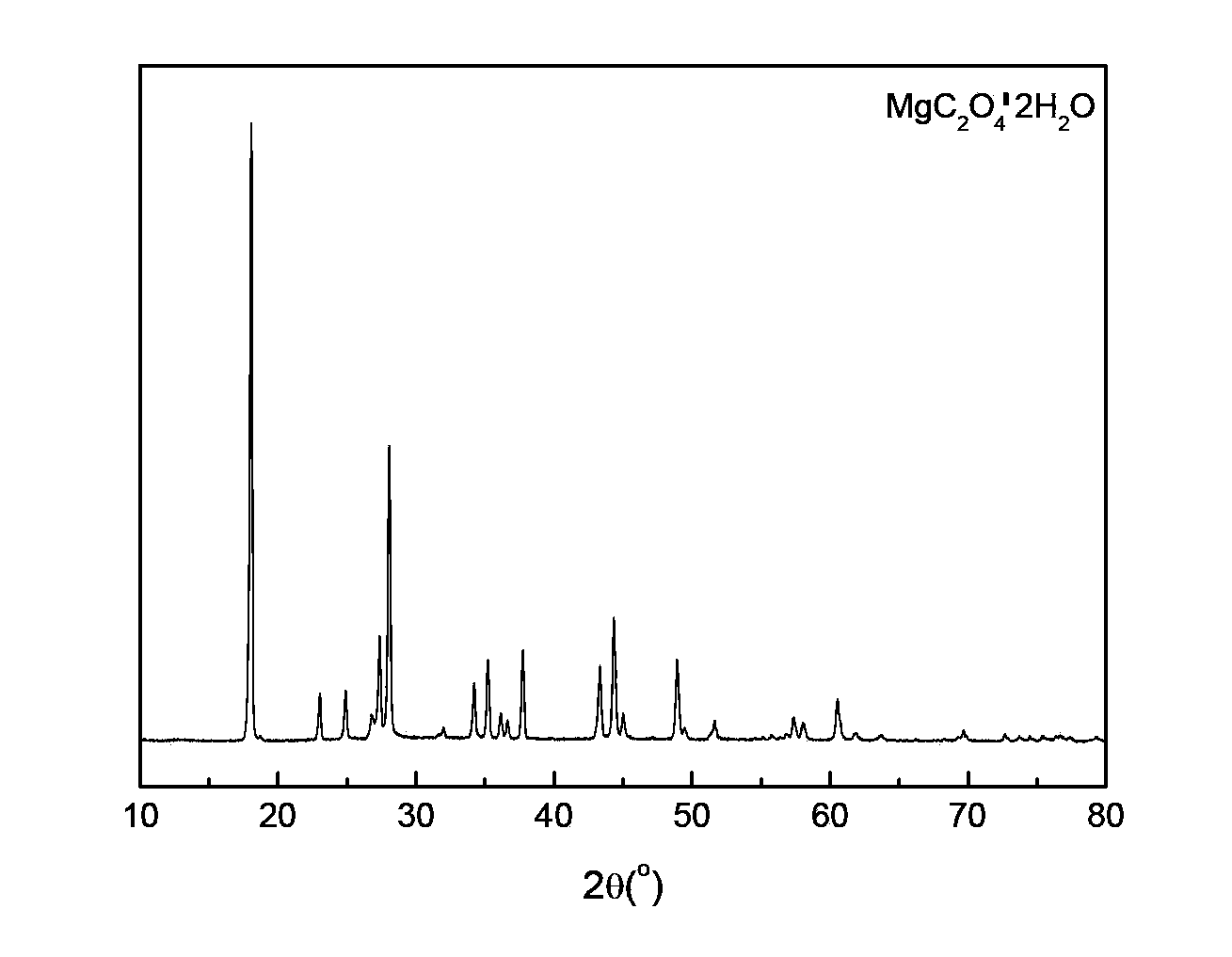

[0027] Nano MgC 2 o 4 The preparation method: magnesium chloride hexahydrate with a molar ratio of 50:1:50, disodium oxalate tetraacetate (C 10 h 14 N 2 o 8 Na 2 2H 2 O) and sodium oxalate were dissolved in distilled water to make a solution, in which the concentration of magnesium chloride was 0.5mol / L, stirred for 1h, aged for 20h, dried at 80°C, and roasted at 500°C for 3h to obtain nano-MgC 2 o 4 powder, its particle size is 11.8nm, its XRD characterization spectrum is as follows figure 1 shown.

Embodiment 2

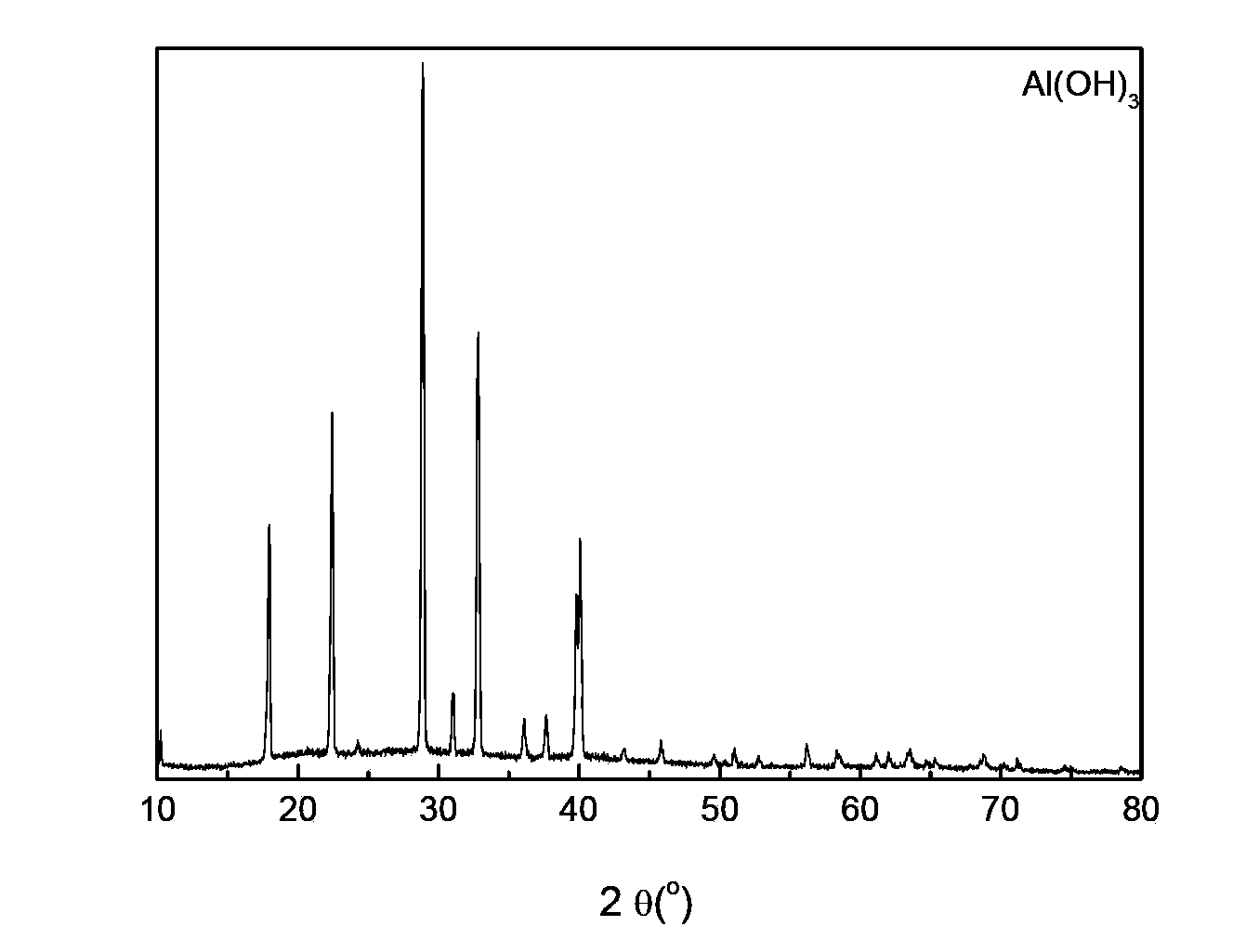

[0029] Nano-Al(OH) 3 Preparation method: prepare aluminum nitrate and ammonium bicarbonate solutions with mass fractions of 27% and 12%, respectively. Add a certain amount of CTAB into the aluminum nitrate solution, the ratio of aluminum nitrate and CTAB is 1:0.006, and stir to obtain a clear solution. Then the ammonium bicarbonate solution was slowly added dropwise to the vigorously stirred aluminum nitrate solution. After the dropwise addition, the stirring was continued for 1 h, aged for 48 h, and the wet gel was dried at 80°C to obtain nano-Al(OH) 3 powder, its particle size is 37.8nm, its XRD characterization spectrum is as follows figure 2 shown.

Embodiment 3

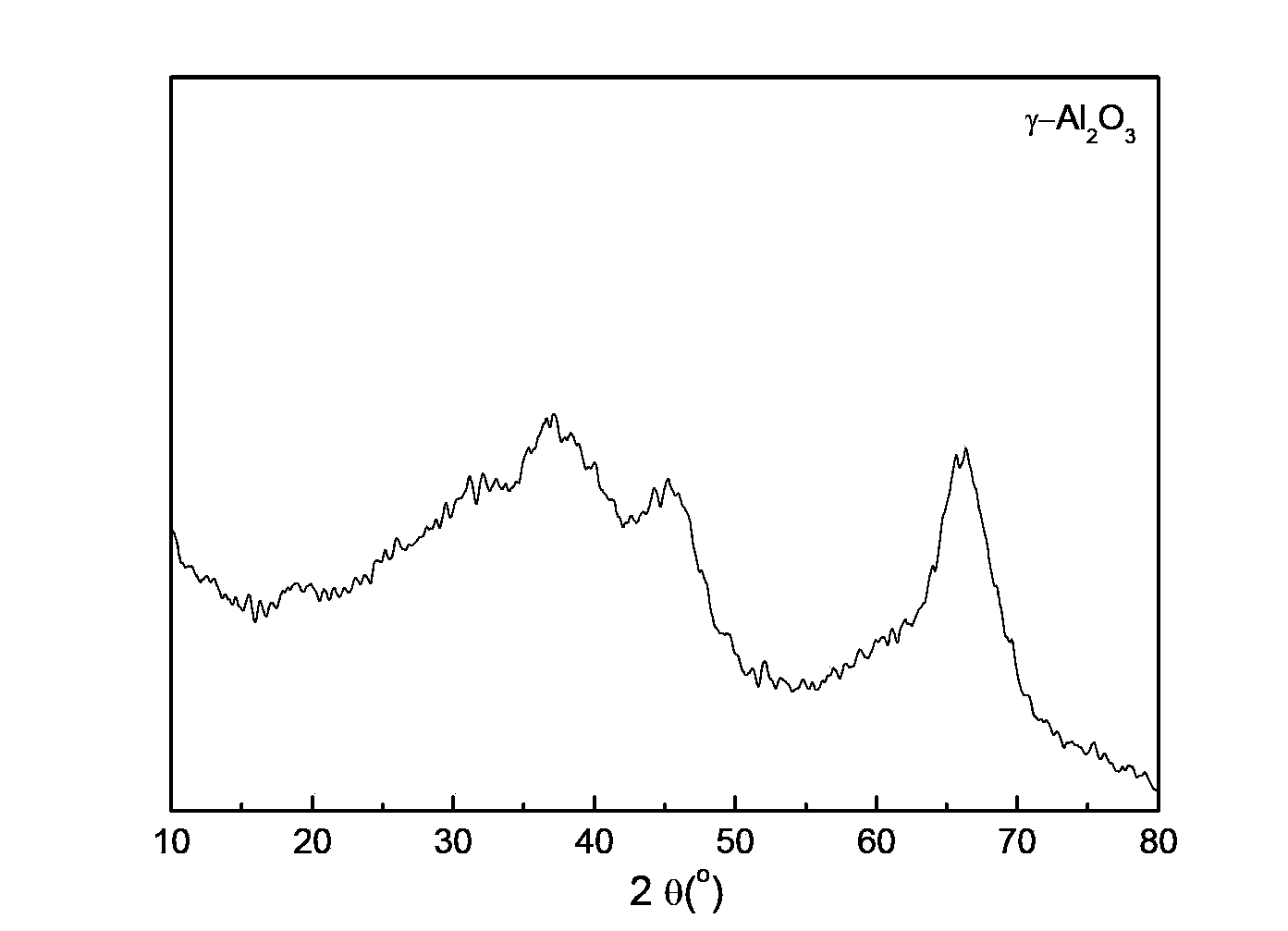

[0031] Nano γ-Al 2 o 3 Preparation method: the nano-Al(OH) prepared in Example 2 3 The powder was calcined at 500°C for 3h to obtain nanometer γ-Al 2 o 3 powder, its particle size is 18.7nm, its XRD characterization spectrum is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com