High-efficiency high pressure gas leak detection method

A high-pressure gas, high-pressure detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc. Can not be used on site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

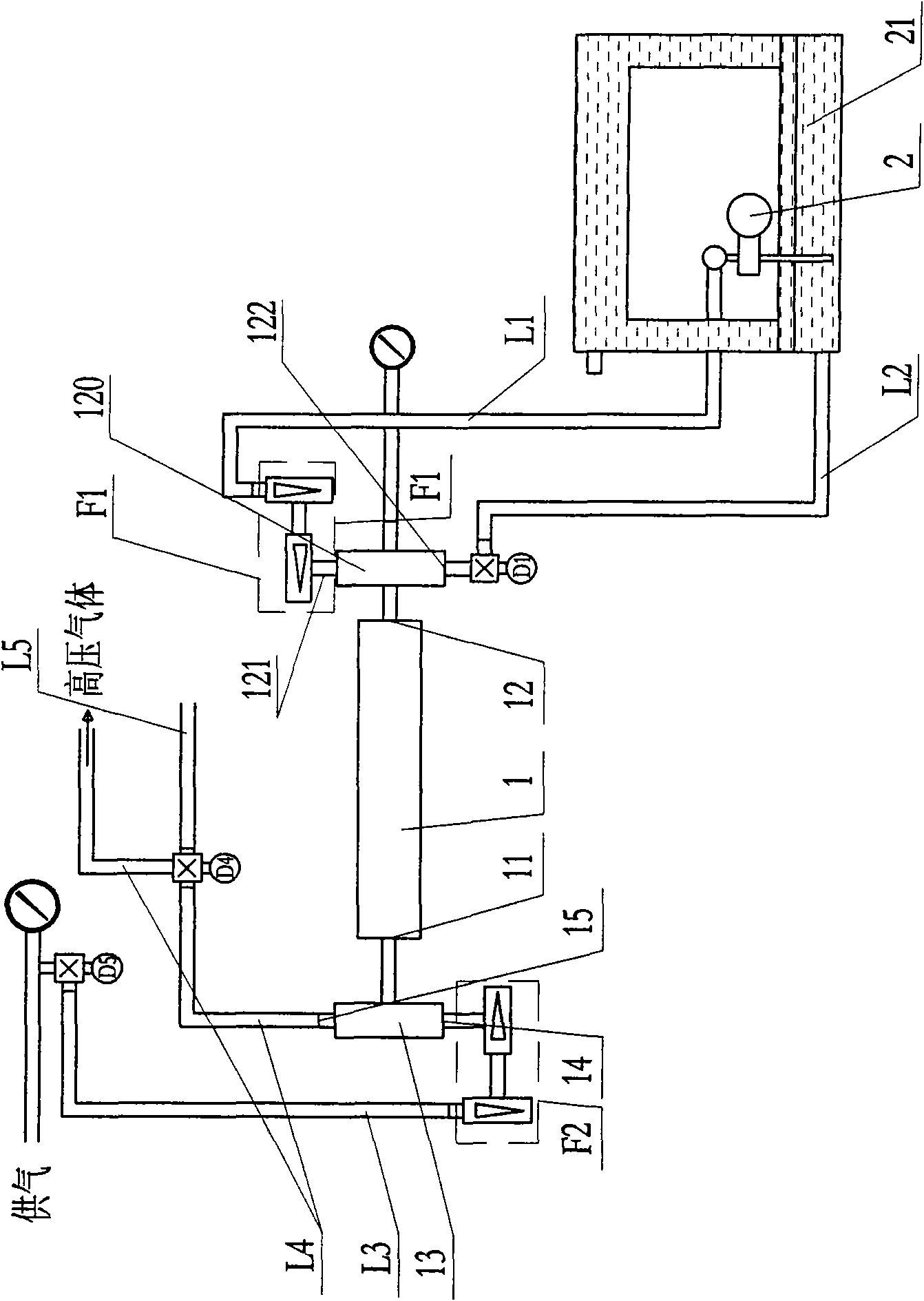

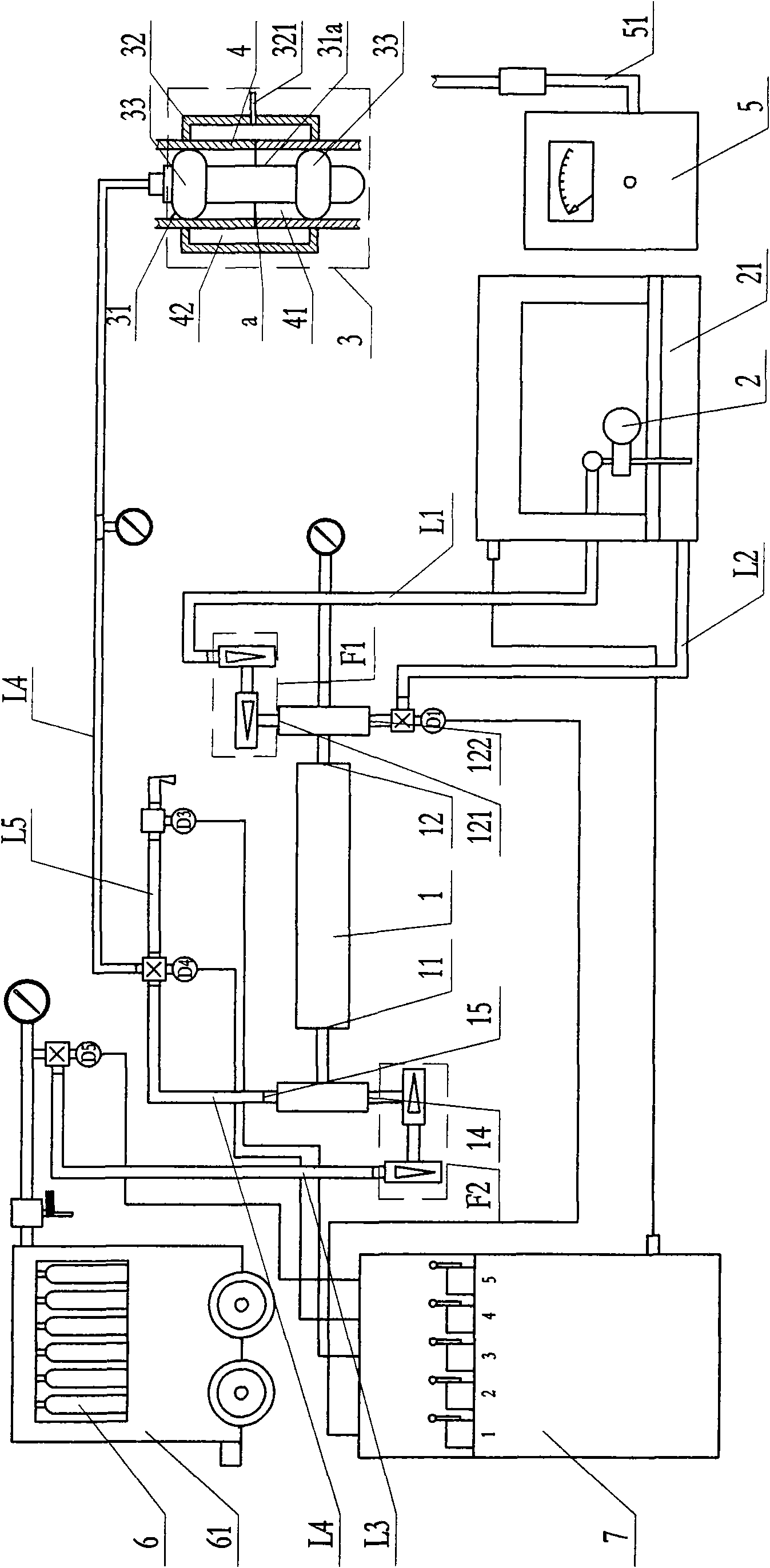

[0052] The high-efficiency high-pressure gas leak detection method provided by the present invention is carried out in equipment comprising a power part, an accumulator and a detection tool, and the equipment includes:

[0053] The power part, which includes a water pump, the water pump is driven by an engine or a motor, and the engine is suitable for field operations;

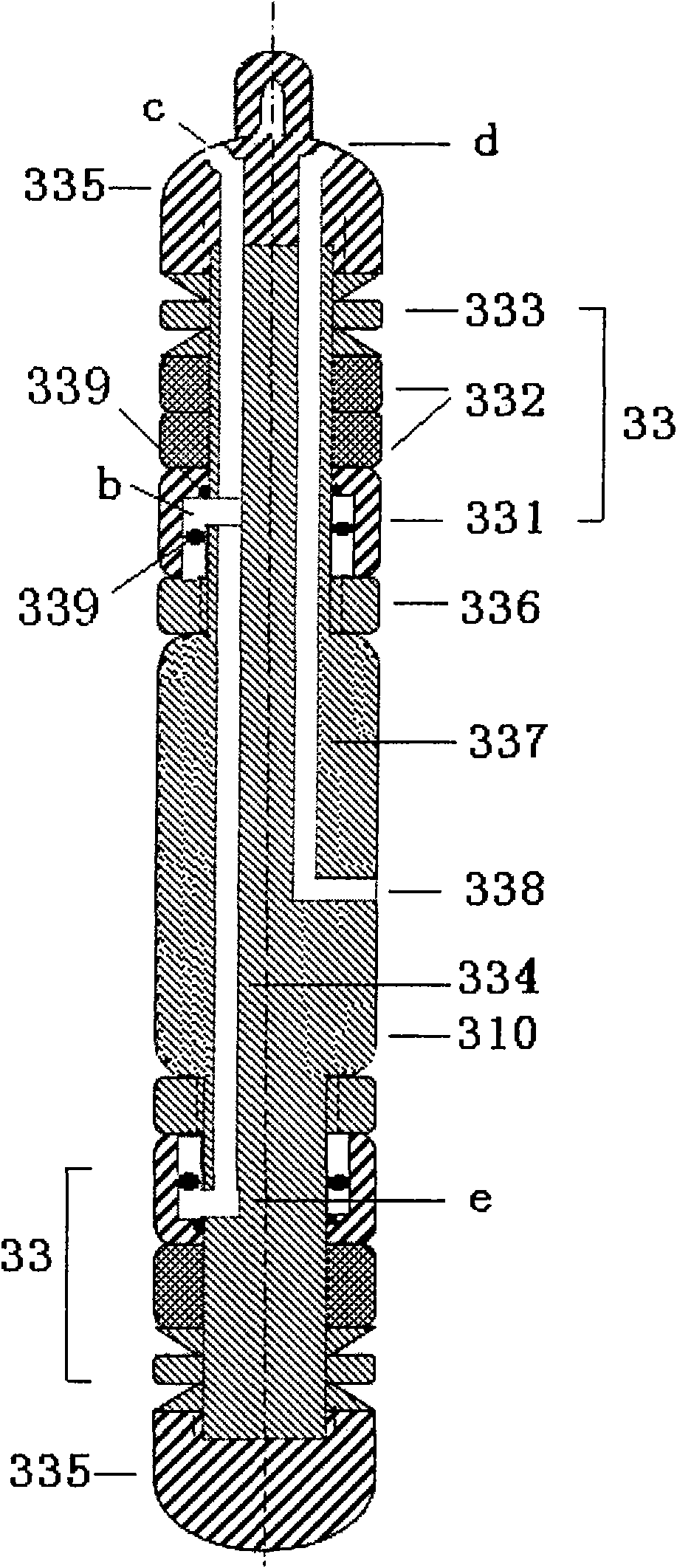

[0054] The detection tool includes a sealing tool and a detection gas collection sleeve.

[0055] The accumulator includes a pressurized container with a high-pressure detection gas outlet and a low-pressure detection gas inlet. The high-pressure detection gas outlet is connected to the sealing tool through a high-pressure exhaust pipe, and the low-pressure detection gas inlet is connected to the Gas source connection; the lower end of the pressurized container is provided with a high-pressure liquid inlet and a liquid discharge port, the high-pressure liquid inlet is connected to the high-pressure liquid outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com