Composite facing material of fire-fighting chemical protective clothing based on electrostatic spinning fiber film

A composite fabric and fiber film technology, applied in clothing, clothing, applications, etc., can solve the problems of the film being difficult to degrade in nature, the protection effect is reduced, etc., to improve the water pressure resistance strength and permeability, light weight, strong air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

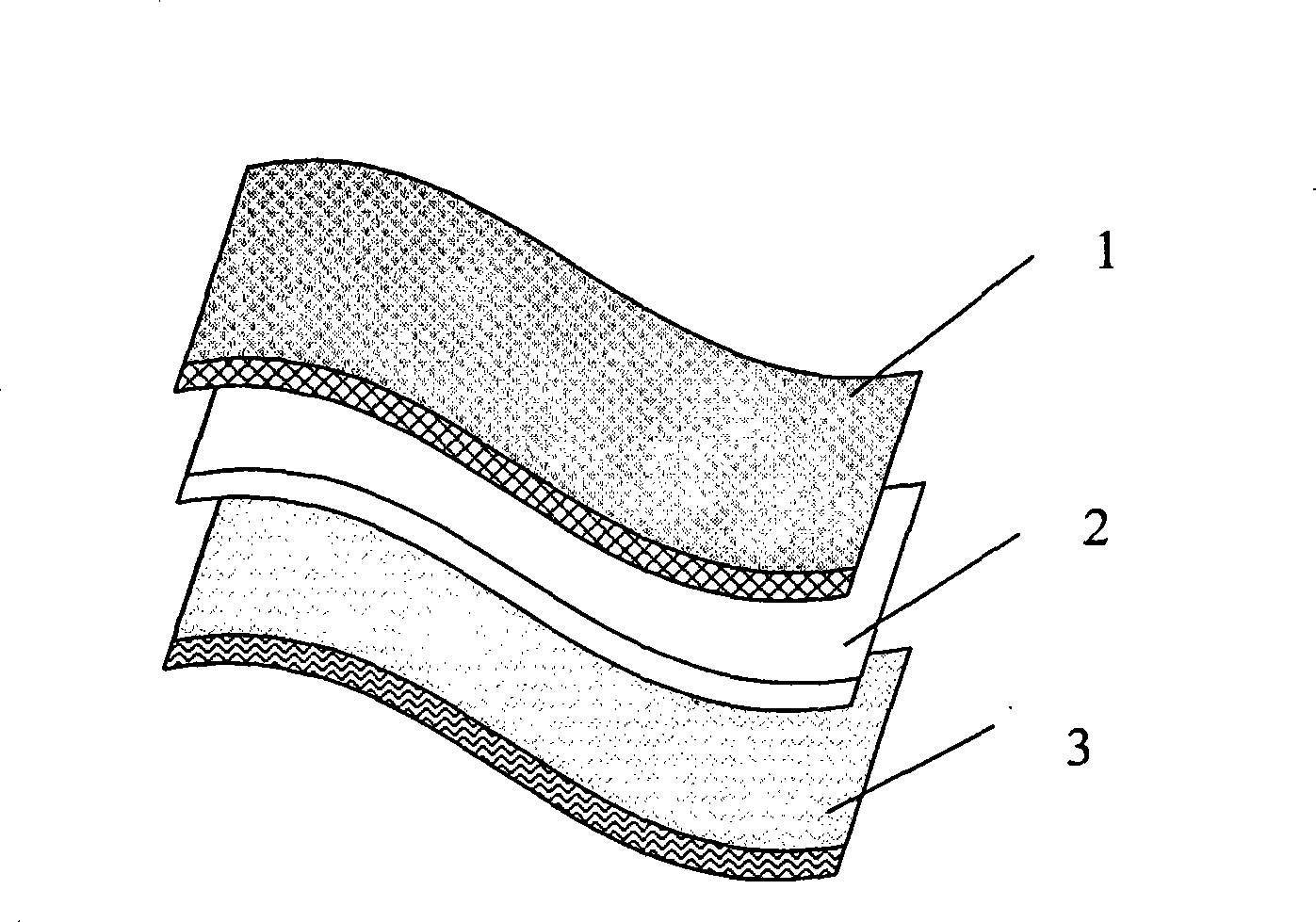

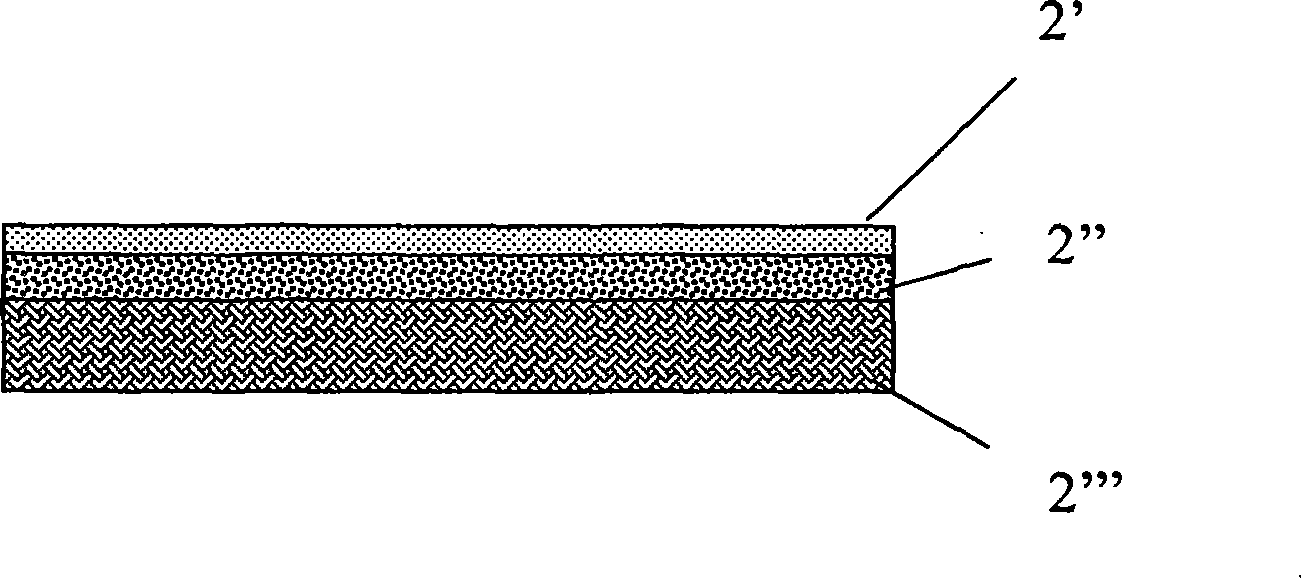

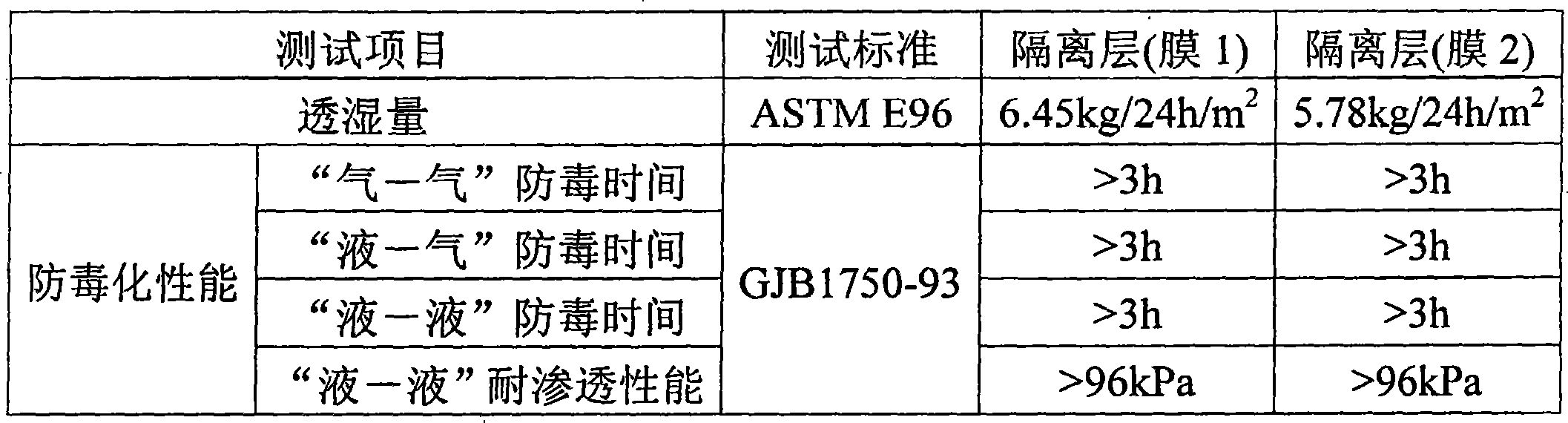

[0025] Flame retardant and fireproof outer layer 1 is Pure spun flame-retardant fabric, the interwoven organic conductive fiber spacing is 10mm; the anti-chemical isolation layer 2 is a laminated composite material of electrospun fiber film, base fabric, and activated carbon cloth; the heat insulation layer 3 is 100% arylsulfone fiber insulation hot felt. The test values of various indicators of the flame-retardant outer layer 1 and the heat-insulating protective layer 3 are shown in Table 2.

[0026] Table 2.

[0027]

Embodiment 2

[0029] Flame-retardant and fire-resistant outer layer 1 is flame-retardant cotton (FR Cotton) fabric, and the proportion of blended metal conductive fiber is 2.0%. 100% Fiber felt. The test values of various indicators of the flame-retardant outer layer 1 and the heat-insulating protective layer 3 are shown in Table 3.

[0030] table 3

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com