Permanently anti-static polyolefin master batch and preparation method thereof

A polyolefin and antistatic technology, applied in the field of permanent antistatic polyolefin masterbatch and its preparation, can solve the problems of high polymer permanent antistatic agent products, such as large addition amount, limited color and high price, and achieve excellent antistatic properties. Static effect, stable anti-static effect, slight effect on color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

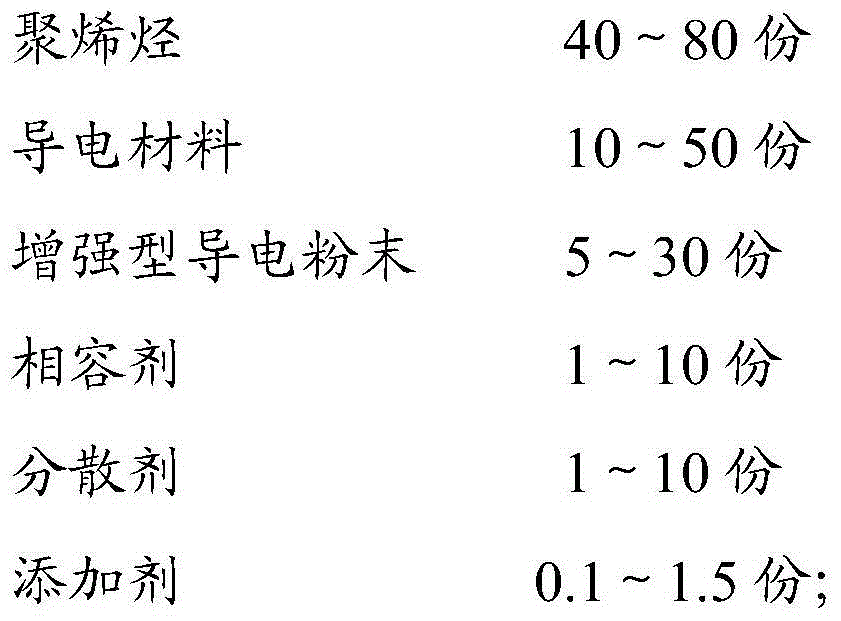

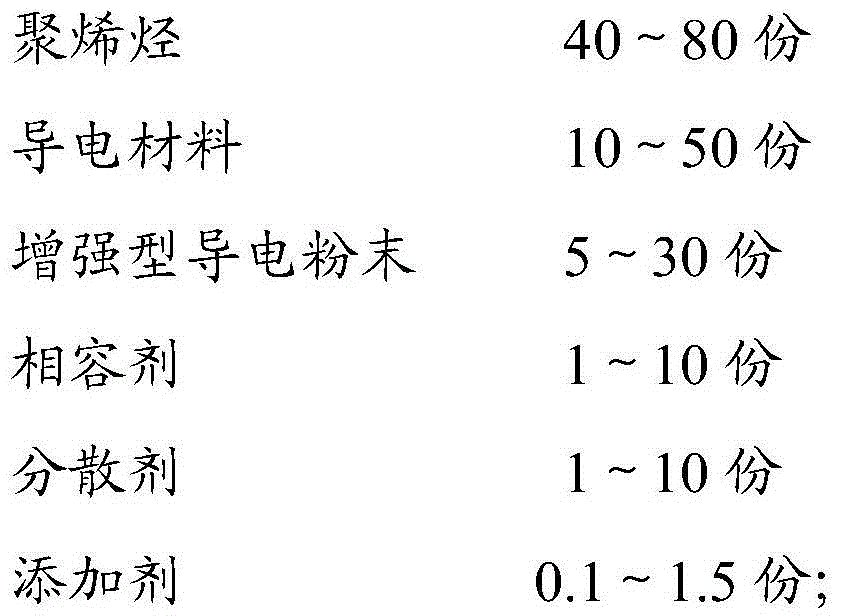

[0030] A kind of permanent antistatic polyolefin masterbatch, comprising polyolefin (PE) 40 parts by weight, conductive material (conductive polymer composite material containing polyacetylene) 50 parts, enhanced conductive powder (carbon black powder) 5 parts, compatibilizer (maleic anhydride graft polymer) 1.5 parts, dispersant (polyethylene wax) 2 parts and additive 1.5 parts.

Embodiment 2

[0032] A kind of permanent antistatic polyolefin masterbatch, comprising polyolefin (PVC) 45 parts by weight, conductive material (containing polypyrrole conductive polymer composite material) 20 parts, reinforced conductive powder (carbon fiber) 25 parts 8 parts, 8 parts of compatibilizer (ethylene-methyl acrylate copolymer acid), 10 parts of dispersant (polypropylene wax) and 1 part of additive.

Embodiment 3

[0034] A kind of permanent antistatic polyolefin masterbatch, comprising polyolefin (TPE) 50 parts by weight, conductive material (containing the conductive polymer composite material of polyparaphenylene vinylene) 33 parts, reinforced conductive powder (iron Powder) 5 parts, compatibilizer (methacrylic acid) 10 parts, dispersant (zinc stearate) 1.5 parts and additive 0.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com