Polyelectrolyte composite solution for flame-retardant treatment of cotton fabric and preparation method and application thereof

A compound solution and flame retardant treatment technology, which is applied in fiber treatment, flame retardant fibers, textiles and papermaking, etc., can solve the problems of cumbersome preparation process and achieve the effect of simple and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

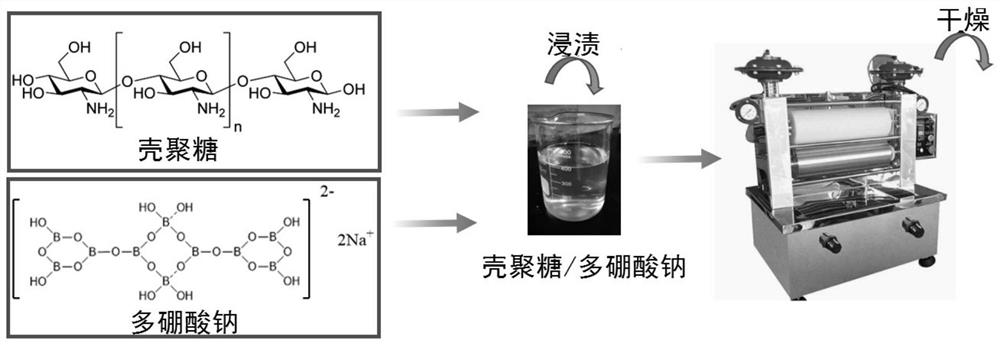

[0046] Preparation of polyelectrolyte complex solution:

[0047] 4 g of acetic acid and 194 g of deionized water were used to prepare an acetic acid solution, and 4 g of chitosan was added to the above solution for ultrasonic dispersion for 10 minutes, and then magnetically stirred for 2 h at room temperature to obtain a 2 wt % chitosan solution.

[0048] Add 20g of boric acid and 25g of borax into 100ml of hot water at 100°C, stir for 1h, and then cool to room temperature. Then add 230ml of deionized water to dilute, and magnetically stir for 2h to obtain a 12wt% sodium polyborate solution.

[0049] Take 200ml 2wt% chitosan solution and 200ml 12wt% sodium polyborate solution and mix to obtain about 400ml 1wt% chitosan and 6wt% polyelectrolyte composite solution, and let it stand for 2h.

[0050] Application of the above-mentioned polyelectrolyte composite solution in the flame-retardant treatment of cotton fabrics:

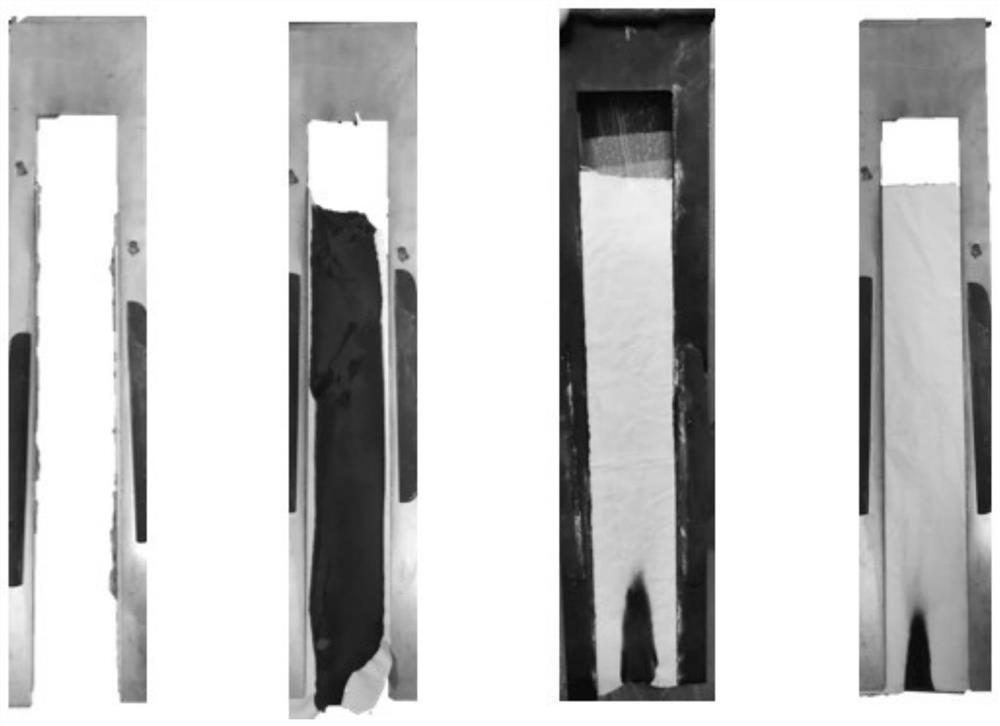

[0051] Cook the cotton fabric in 1% NaOH solution for 30m...

Embodiment 2

[0053] Preparation of polyelectrolyte complex solution:

[0054] 4 g of acetic acid and 192 g of deionized water were used to prepare an acetic acid solution, and 4 g of chitosan was added to the solution for ultrasonic dispersion for 10 minutes, and then magnetically stirred for 2 h at room temperature to obtain a 4 wt % chitosan solution.

[0055] Add 20g of boric acid and 25g of borax into 100ml of hot water at 100°C, stir for 1h, and then cool to room temperature. Then add 176ml of deionized water for dilution, and magnetically stir for 2h to obtain a 14wt% sodium polyborate solution.

[0056] Get the chitosan solution of 200ml 4wt% and the sodium polyborate solution of 200ml 14wt% mix, obtain the polyelectrolyte complex solution of the 1wt% chitosan of about 400ml and 7wt% sodium polyborate. Let stand for 2h.

[0057] Application of the above-mentioned polyelectrolyte composite solution in the flame-retardant treatment of cotton fabrics:

[0058] Cook the cotton fabric i...

Embodiment 3

[0060] Preparation of polyelectrolyte complex solution:

[0061] 4 g of acetic acid and 194 g of deionized water were used to prepare an acetic acid solution, and 4 g of chitosan was added to the above solution for ultrasonic dispersion for 10 minutes, and then magnetically stirred for 2 h at room temperature to obtain a 2 wt % chitosan solution.

[0062] Add 20g of boric acid and 25g of borax into 100ml of hot water at 100°C, stir for 1h, and then cool to room temperature. Then add 230ml of deionized water to dilute, and magnetically stir for 2h to obtain a 12wt% sodium polyborate solution.

[0063] Get 200ml 2wt% chitosan solution and 200ml 12wt% sodium polyborate solution and mix to obtain about 400ml 1wt% chitosan and 6wt% sodium polyborate polyelectrolyte complex solution, let stand for 2h.

[0064] Application of the above-mentioned polyelectrolyte composite solution in the flame-retardant treatment of cotton fabrics:

[0065] The cotton fabric was boiled in 1wt% NaOH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com