Jewelry surface protective film and jewelry processing technology

A surface protective film, protective film technology, applied in jewelry, application, coating and other directions, can solve the problem of jewelry tarnishing, etc., to achieve the effect of good durability, good friction resistance and elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

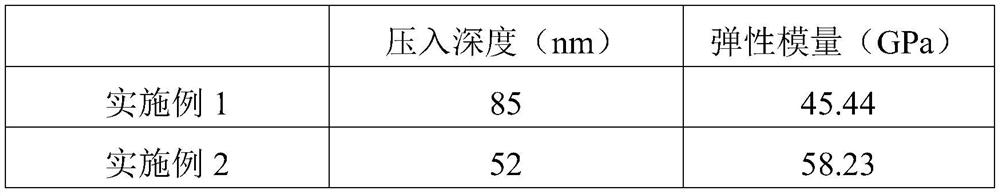

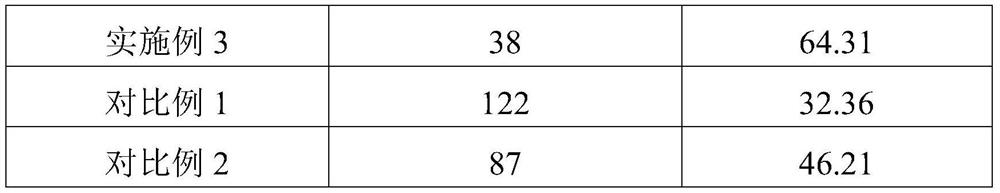

Examples

Embodiment 1

[0051] A preparation method for a jewelry surface protective film, the steps are:

[0052] S1 Mix 100g of methyltriethoxysilane and 200g of glacial acetic acid for 15min under stirring at 300r / min to obtain system I; add system I to 2000g of constantly stirring silica sol at a dropping rate of 20g / min , continue to stir for 60min to obtain activated silica sol;

[0053] S2 At 65°C, 2000g of water-based polyurethane resin, 50g of polyvinylidene fluoride, 200g of nano-titanium dioxide, 1000g of N,N-dimethylacetamide, 10g of carboxymethyl ethyl cellulose, and 1000g of the activated carbon dioxide of step S1 Mix the silica sol for 60 minutes under stirring; naturally cool to 25°C to obtain a protective film treatment precursor;

[0054] S3 uniformly spray the protective film treatment precursor in step S2 onto the pretreated jewelry surface with a spray gun, and let it dry naturally for 2 hours at a temperature of 25° C. to obtain jewelry with a jewelry surface protective film wi...

Embodiment 2

[0057] A preparation method for a jewelry surface protective film, the steps are:

[0058] S1 Mix 100g of methyltriethoxysilane and 200g of glacial acetic acid for 15min under stirring at 300r / min to obtain system I; add system I to 2000g of constantly stirring silica sol at a dropping rate of 20g / min In, continue to stir for 60min to obtain system II;

[0059] S2 Mix 200g of cyclopentasiloxane, 400g of zirconium tetra-tert-butoxide, and 200g of glacial acetic acid for 30min under stirring at a speed of 500r / min to obtain system III; add 2000g of water to the In the continuously stirring system III, continue stirring for 20 minutes to obtain system IV;

[0060] S3 Add the system IV of step S2 to the system II of step S1 at a dropping rate of 40 g / min, stir at a speed of 400 r / min and continue stirring for 6 hours to obtain an activated silica sol;

[0061] S4 At 65°C, 2000g water-based polyurethane resin, 50g polyvinylidene fluoride, 200g nano-titanium dioxide, 1000g N,N-dim...

Embodiment 3

[0065] A preparation method for a jewelry surface protective film, the steps are:

[0066] S1 Mix 100g of methyltriethoxysilane and 200g of glacial acetic acid for 15min under stirring at 300r / min to obtain system I; add system I to 2000g of constantly stirring silica sol at a dropping rate of 20g / min In, continue to stir for 60min to obtain system II;

[0067] S2 Mix 200g of cyclopentasiloxane, 400g of zirconium tetra-tert-butoxide, 200g of glacial acetic acid, and 1g of 3-methyl-2-benzothiazolone hydrazone hydrochloride under stirring at a speed of 500r / min for 30min, System III was obtained; 2000g of water was added to the constantly stirring system III at a drop rate of 50g / min, and the stirring was continued for 20min to obtain system IV;

[0068] S3 Add the system IV of step S2 to the system II of step S1 at a dropping rate of 40 g / min, stir at a speed of 400 r / min and continue stirring for 6 hours to obtain an activated silica sol;

[0069] S4 At 65°C, 2000g water-bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com