A kind of preparation method of corn modified starch

A technology of corn modified starch and corn starch, which is applied in the field of modified starch, can solve the problems of poor water retention and poor taste of meat, and achieve the effects of improving water retention, increasing water content and pH value, and reducing drip loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

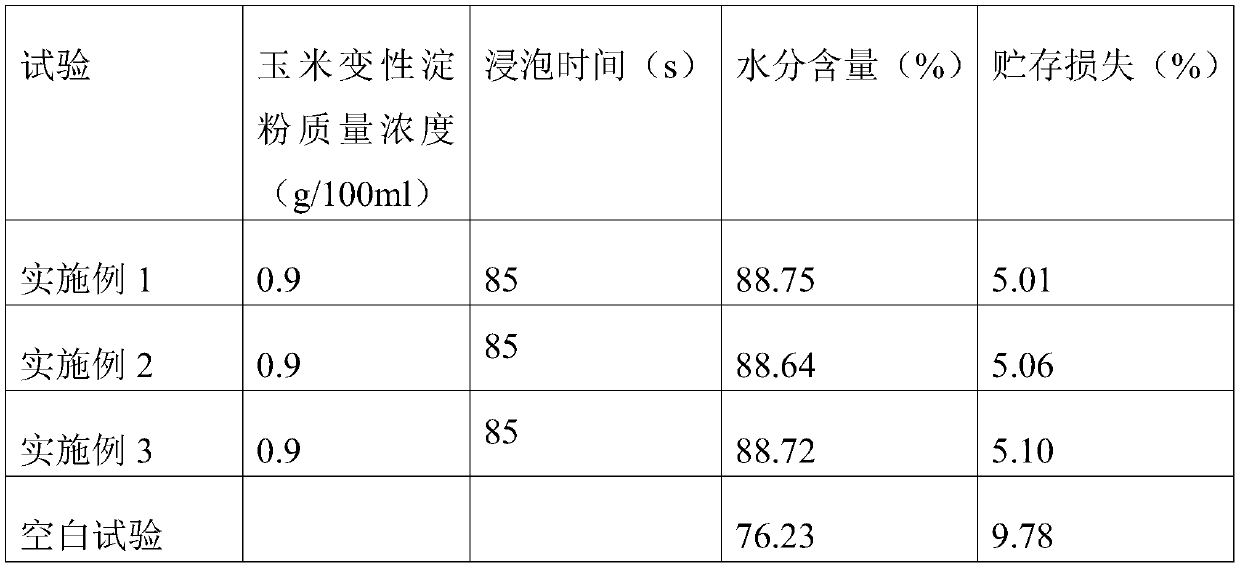

Examples

Embodiment 1

[0022] A preparation method of modified corn starch, comprising the following steps:

[0023] (1) Prepare 2 tons of cornstarch required for production, make slurry with cornstarch and water, control its Baume degree to be the cornstarch slurry of 19Be;

[0024] (2) add sodium chlorate and amylase in the cornstarch slurry that step (1) makes, stir, the weight that adds sodium chlorate is 0.6% of cornstarch raw material weight; The weight that adds amylase is cornstarch raw material 0.4% by weight, reacted for 40min at a temperature of 50-60°C;

[0025] (3) add hydrogen peroxide and copper sulfate in the cornstarch slurry after step (2) process and mix; The consumption of copper sulfate is 0.09% of the weight of cornstarch raw material, the weight that adds hydrogen peroxide is cornstarch raw material weight 0.8% of;

[0026] (4) Add sodium chloroacetate, acetic anhydride, cross-linking agent and hydroxypropyl distarch phosphate to the slurry prepared in step (3), and react fo...

Embodiment 2

[0030] A preparation method of modified corn starch, comprising the following steps:

[0031] (1) Prepare 2 tons of cornstarch required for production, make slurry with cornstarch and water, control its Baume degree to be the cornstarch slurry of 16Be;

[0032] (2) add sodium chlorate and amylase in the cornstarch slurry that step (1) makes, stir, the weight that adds sodium chlorate is 0.4% of cornstarch raw material weight; The weight that adds amylase is cornstarch raw material 0.7% by weight, reacted for 60min at a temperature of 50-60°C;

[0033] (3) add hydrogen peroxide and copper sulfate in the corn starch slurry after step (2) process and mix; The consumption of copper sulfate is 0.08% of the weight of corn starch raw material, and the weight of adding hydrogen peroxide is the corn starch raw material weight 1.1% of;

[0034] (4) Add sodium chloroacetate, acetic anhydride, cross-linking agent and hydroxypropyl distarch phosphate to the slurry prepared in step (3), a...

Embodiment 3

[0038] A preparation method of modified corn starch, comprising the following steps:

[0039] (1) prepare 2 tons of cornstarch required for production, make slurry with cornstarch and water, control its Baume degree to be the cornstarch slurry of 22Be;

[0040] (2) add sodium chlorate and amylase in the cornstarch slurry that step (1) makes, stir, the weight that adds sodium chlorate is 0.9% of cornstarch raw material weight; The weight that adds amylase is cornstarch raw material 0.3% by weight, reacted for 30 minutes at a temperature of 50-60°C;

[0041] (3) add hydrogen peroxide and copper sulfate in the corn starch slurry after step (2) process and mix; 0.6% of;

[0042] (4) adding sodium chloroacetate, acetic anhydride, cross-linking agent and hydroxypropyl distarch phosphate to the slurry prepared in step (3), and reacting for 4 hours at a temperature of 40-50° C., then Add hydrochloric acid to adjust the pH value to 7;

[0043] The weight of adding sodium chloroacet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com