Nanooxide-doped red solder glass and preparation method thereof

A nano-oxide and solder glass technology is applied in the field of nano-oxide-doped red solder glass and its preparation, so as to achieve the effects of large forming area, enhancing sealing strength and thermal stability, and reducing softening temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

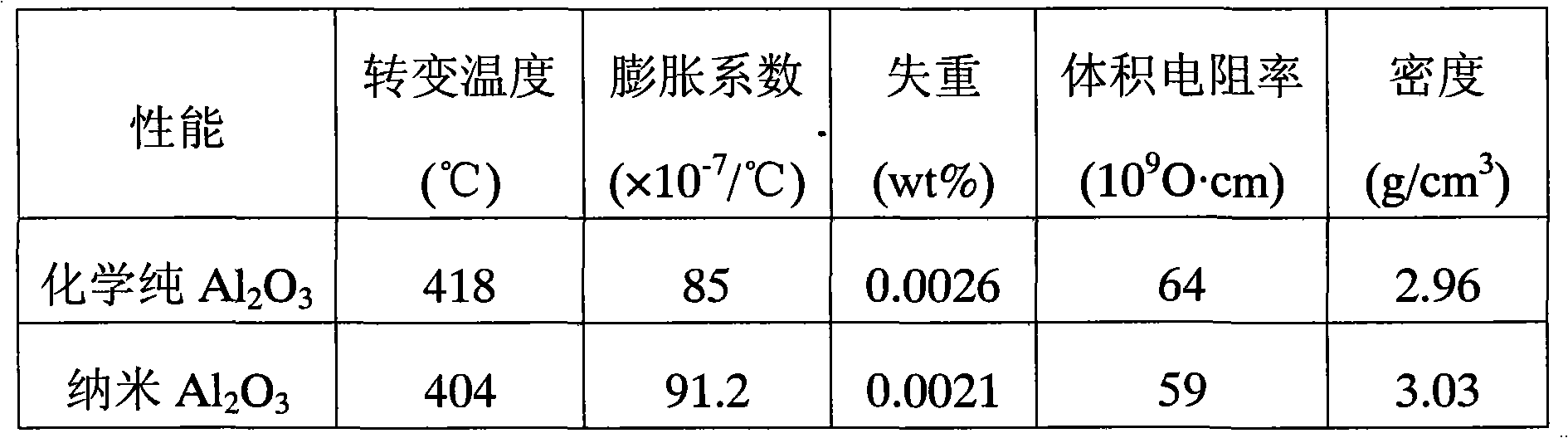

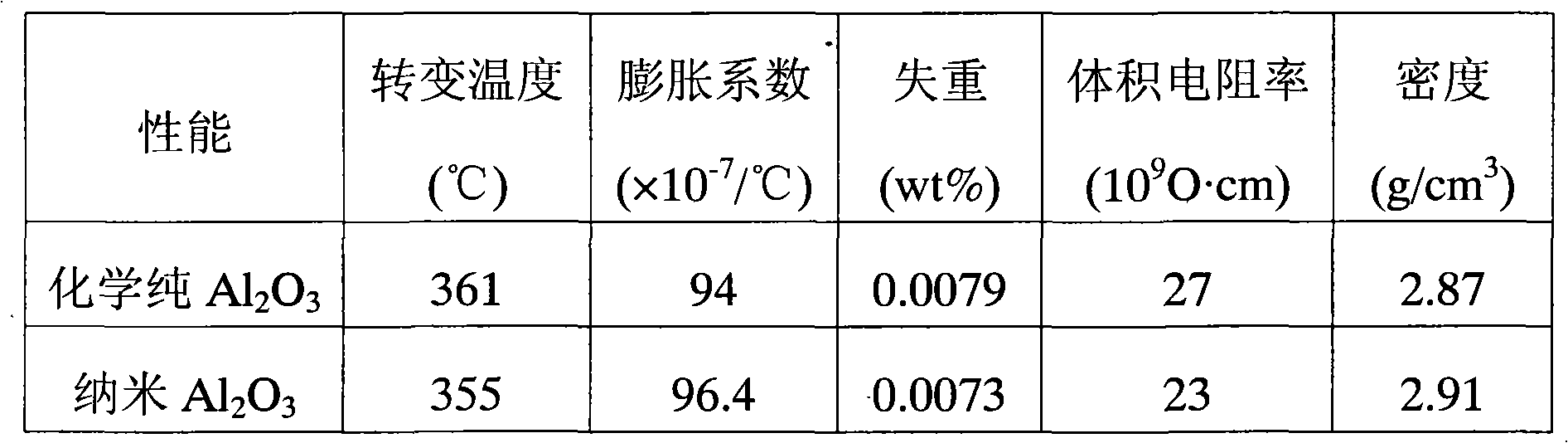

Embodiment 1

[0045] (1) The composition of the raw materials is as follows in molar percentage:

[0046] P 2 o 5 35%

[0047] ZnO 44%

[0048] B 2 o 3 10%

[0049] al 2 o 3 3%

[0050] SiO 2 0.5%

[0051] Na 2 O 5%

[0052] MgO 0.3%

[0053] Li 2 O 0.3%

[0054] Fe 2 o 3 1%

[0055] MnO 2 0.7%

[0056] CuO 0.2%

[0057] (2) Introduction of raw materials:

[0058] Each raw material except Al 2 o 3 All are chemically pure grade raw materials, of which ZnO, SiO 2 , Fe 2 o 3 , MnO 2 are introduced as oxides, P 2 o 5 Introduced as phosphorus pentoxide, B 2 o 3 Introduced with boric acid, CuO introduced with cuprous oxide, MgO, Na 2 O. Li 2 O was introduced in the form of carbonate, Al 2 o 3 Gamma nano-alumina with an average particle size of 10 nm is used for introduction.

[0059] (3) Preparation method:

[0060] ① Weigh each raw material according to mole percentage a...

Embodiment 2

[0072] (1) The composition of the raw materials is as follows in molar percentage:

[0073] P 2 o 5 40%

[0074] ZnO 34.5%

[0075] B 2 o 3 10%

[0076] al 2 o 3 3%

[0077] SiO 2 1%

[0078] Na 2 O 4.5%

[0079] MgO 4%

[0080] Li 2 O 0.5%

[0081] Fe 2 o 3 0.5

[0082] MnO 2 1.5%

[0083] CuO 0.5%

[0084] (2) Introduction of raw materials:

[0085] Each raw material except Al 2 o 3 All are chemically pure grade raw materials, of which ZnO, SiO 2 , Fe 2 o 3 , MnO 2 are introduced as oxides, P 2 o 5 Introduced as phosphorus pentoxide, B 2 o 3 Introduced with boric acid, CuO introduced with cuprous oxide, MgO, Na 2 O. Li 2 O was introduced in the form of carbonate, Al 2 o 3 Gamma nano-alumina with an average particle size of 10 nm is used for introduction.

[0086] (3) Preparation method:

[0087] ① Weigh each raw material according to mole p...

Embodiment 3

[0096] (1) The composition of raw materials in molar percentage is

[0097] P 2 o 5 45%

[0098] ZnO 38%

[0099] B 2 o 3 5%

[0100] Al 2 o 3 1%

[0101] SiO 2 2.3%

[0102] Na 2 O 5%

[0103] MgO 1

[0104] Li 2 O 0.3

[0105] Fe 2 o 3 1.5%

[0106] MnO 2 0.2

[0107] CuO 0.7%

[0108] (2) Introduction of raw materials:

[0109] Each raw material except Al 2 o 3 All are chemically pure grade raw materials, of which ZnO, SiO 2 , Fe 2 o 3 , MnO 2 are introduced as oxides, P 2 o 5 Introduced as phosphorus pentoxide, B 2 o 3 Introduced with boric acid, CuO introduced with cuprous oxide, MgO, Na 2 O. Li 2 O was introduced in the form of carbonate, Al 2 o 3 Gamma nano-alumina with an average particle size of 10 nm is used for introduction.

[0110] (3) Preparation method:

[0111] ① Weigh each raw material according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com