Alkali-resistant aluminosilicate glass and application thereof

An aluminosilicate glass and alkali-resistant technology, applied in the field of special glass materials and their preparation, can solve the problems of reducing the transmittance of windows, high transmittance, increasing the complexity of replacement operations, and improving production and labor conditions. , High transmittance, good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Application in concrete reinforcement:

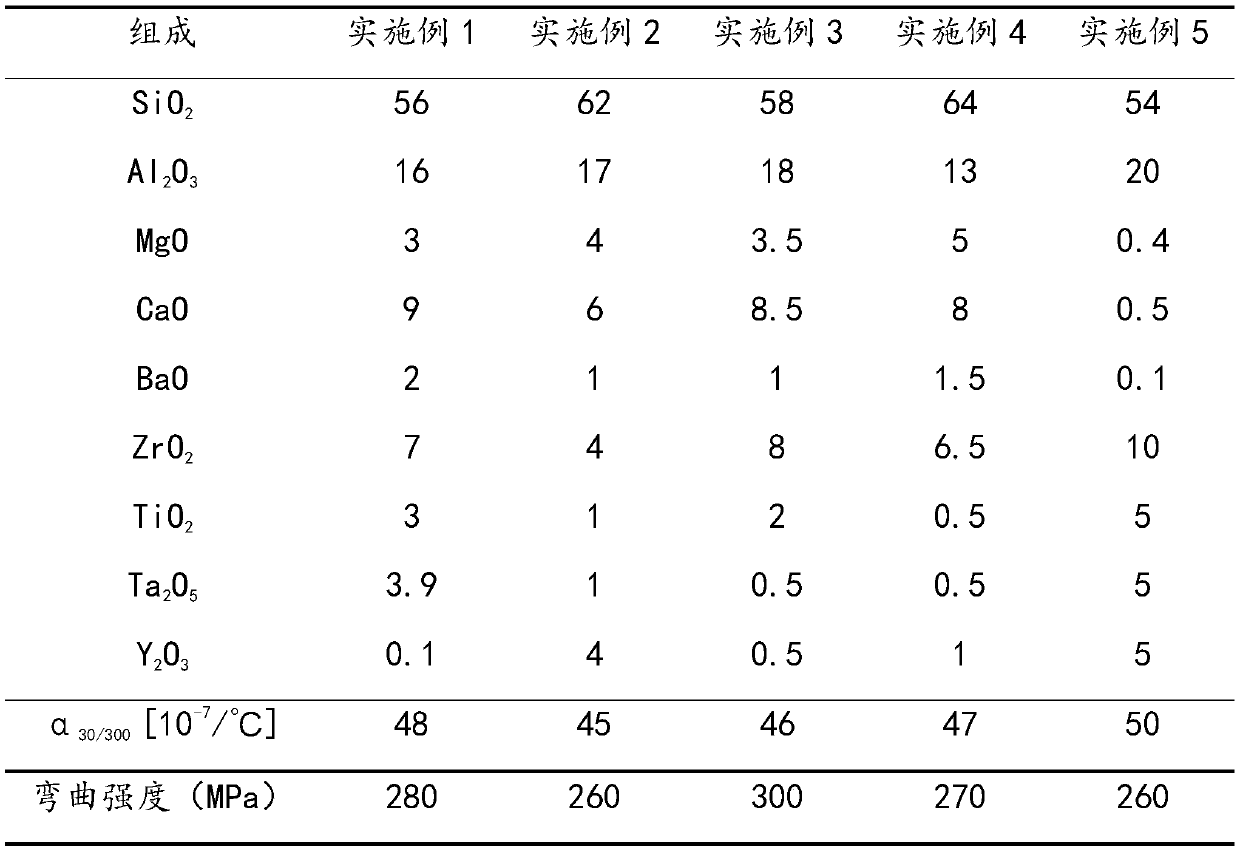

[0063] Chemical composition (wt.%), SiO 2 : 56%; Al 2 o 3 : 16%; MgO: 3%; CaO: 9%; BaO: 2%; ZrO 2 : 7%; TiO 2 : 3%; Ta 2 o 5 : 3.9%; Y 2 o 3 : 0.1%;

[0064] First, select the glass raw material according to the glass composition of Example 1 in Table 1, the raw material requirements, quartz sand (high purity, 150 μm oversize is less than 1%, 45 μm undersize is less than 30%, Fe 2 o 3content less than 1PPm), alumina powder (average particle size 50μm), basic magnesium carbonate (analytical pure), calcium carbonate (analytical pure, average particle size 250μm), barium carbonate (analytical pure, purity ≥ 99.0%), zirconia (analytical pure), titanium oxide (analytical pure), tantalum pentoxide (5N), yttrium trioxide (5N), and the main raw materials in the glass raw materials are treated with iron removal to improve the purity of the glass raw materials oxides such as Fe 2 o 3 etc. are strictly controlled, and the finis...

Embodiment 2

[0066] Applications in lighting or display technology:

[0067] Chemical composition (wt.%), SiO 2 : 62%; Al 2 o 3 : 17%; MgO: 4%; CaO: 6%; BaO: 1%; ZrO 2 : 4%; TiO 2 : 1%; Ta 2 o 5 : 1%; Y 2 o 3 : 4%;

[0068] The actual composition of the glass refers to Example 2 in Table 1, using the same raw materials and raw material requirements as in Example 1, and adopting the same test conditions as in Example 1. Table 1 shows the basic properties of the samples. (1) The average coefficient of linear expansion at 30-300°C is 45×10 -7 / °C; (2) Bending strength 260MPa; (3) Chemical stability level A1, in line with lighting or display technology applications.

Embodiment 3

[0070] Applications in container glass for chemically aggressive liquids:

[0071] Chemical composition (wt.%), SiO 2 : 58%; Al 2 o 3 : 18%; MgO: 3.5%; CaO: 8.5%; BaO: 1%; ZrO 2 : 8%; TiO 2 : 2%; Ta 2 o 5 : 0.5%; Y 2 o 3 : 0.5%;

[0072] The actual composition of the glass refers to Example 3 in Table 1, using the same raw materials and raw material requirements as in Example 1, and adopting the same test conditions as in Example 1. Table 1 shows the basic properties of the samples. (1) The average coefficient of linear expansion at 30-300°C is 46×10 -7 / °C; (2) Bending strength 300MPa; (3) Chemical stability level A1, suitable for application in container glass for chemically erosive liquids.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strain point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com