Air brick for special steel refining and preparation method thereof

A technology of breathable brick and special steel, applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of harsh working environment, shortened service life and increased workload of breathable bricks, and achieves excellent high temperature performance and breathable performance. , The effect of preventing cracks and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

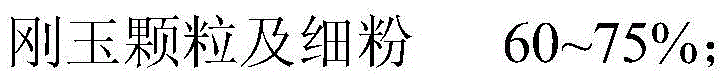

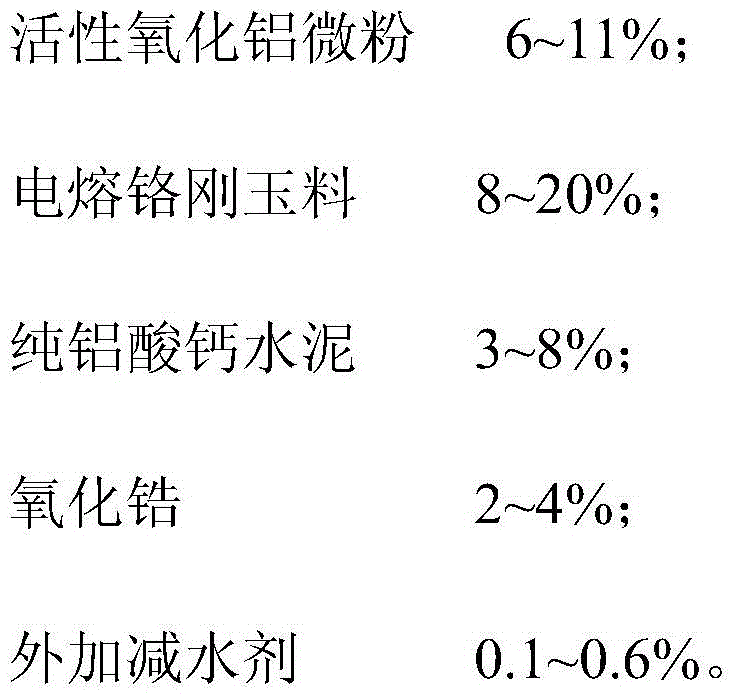

[0032] The percentage that is used for present embodiment to prepare the permeable brick raw material of ladle is:

[0033] The particle size of plate corundum is 6~3mm, 3~1mm, 1~0mm respectively 30%, 20%, 15%; 325 mesh platy corundum fine powder 9%; activated alumina fine powder 6%; 325 mesh fused chromium Corundum fine powder 12% (alumina / chromium oxide = 80 / 18); zirconia 3%; pure calcium aluminate cement 5%; dispersed alumina superplasticizer (additional) 0.5%.

[0034] The preparation method of this embodiment is the same as that of Comparative Example 1, adding 3.66% water of the total mass of solid materials.

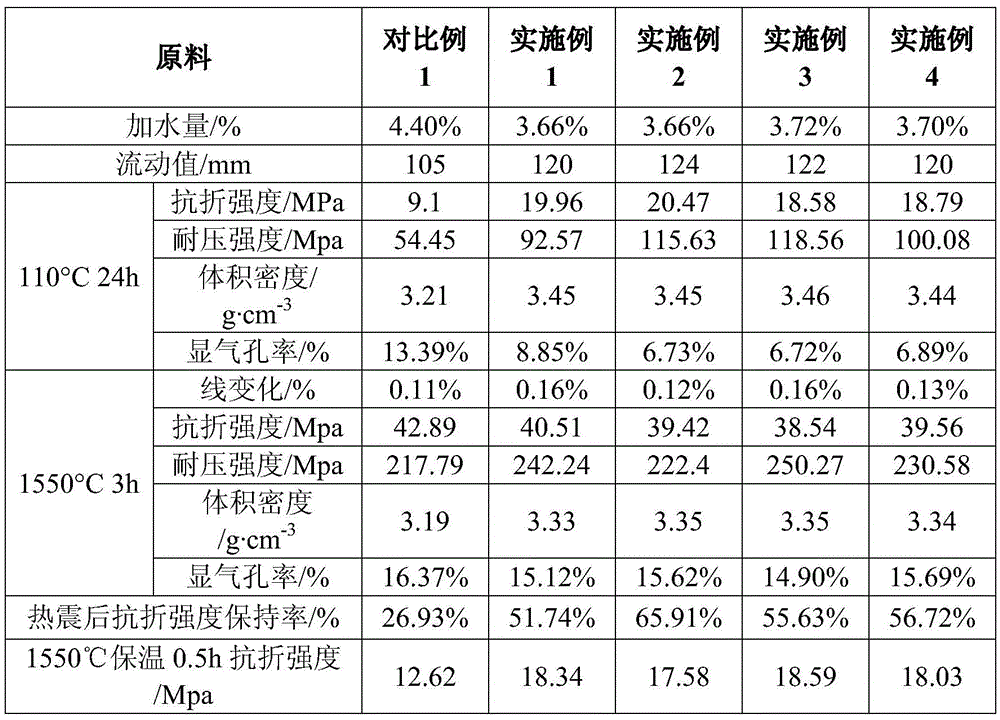

[0035] The results of using the obtained ladle permeable brick:

[0036] It is used in a 150-ton ladle in a domestic steel factory to smelt special steel types. The average number of times of use has reached more than 18 times, and the refining time has exceeded 100 hours. In case of spalling, the service life of traditional ventilation bricks is increased by ab...

Embodiment 2

[0038] The percentage that is used for present embodiment to prepare the permeable brick raw material of ladle is:

[0039] The percentages of platy corundum particle diameters of 6-3mm, 3-1mm, and 1-0mm are 30%, 15% and 16% respectively; white corundum fine powder 200 mesh 3%; platy corundum fine powder 325 mesh 5%; Activated alumina fine powder 8%; fused chromium corundum fine powder 0.5-0mm and 325 mesh fine powder 5% and 9% respectively (alumina / chromium oxide=70 / 28); zirconia 3%; pure calcium aluminate cement 6%; plus 0.3% of dispersed alumina superplasticizer.

[0040] The preparation steps of the present embodiment are as follows:

[0041] (1) First, fully mix corundum 1-0mm and fine powder, activated alumina micro-powder, fused chromium corundum 0.5-0mm particles and fine powder, pure calcium aluminate cement, and dispersed alumina high-efficiency water reducer for 10 minutes, then Add corundum pellets, continue mixing until fully uniform, add clean tap water, the am...

Embodiment 3

[0048] The percentage that is used for the present embodiment to prepare the permeable brick of ladle is:

[0049] The percentages of platy corundum particle sizes of 6-3mm, 3-1mm, and 1-0mm are 33%, 13% and 10% respectively; platy corundum fine powder 325 mesh is 7%; white corundum 3-1mm is 5%; Activated alumina fine powder 6%; fused chromium corundum fine powder 1-0mm and 325 mesh fine powder are 7% and 10% respectively (alumina / chromium oxide=60 / 38), zirconia fine powder 3%; pure calcium aluminate 6% cement; dispersed alumina plus 0.5% superplasticizer.

[0050] The preparation steps of this example are the same as those of Example 2, and water with a total mass of solid materials of 3.72% is added.

[0051] The results of using the obtained ladle permeable brick:

[0052] It is used in a 120-ton ladle in a domestic steel factory to smelt special steel types. The average number of times of use is more than 30 times, and the refining time is more than 150 hours. In case o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com