Anti-oxidation high-bending-resistance iron runner castable

A iron channel castable, anti-oxidation technology, applied in the field of iron channel castable with high oxidation resistance and high bending resistance, to achieve the effect of increasing strength and bulk density, improving various properties, and promoting high temperature densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described further below:

[0016] A high anti-oxidation and anti-bending iron channel castable, the components are proportioned as follows in parts by weight: 5mm2 o 3 2-10 parts, 1-3 parts of calcium boride, 1-10 parts of binder.

[0017] The binder is pure calcium aluminate cement.

[0018] Raw material indicators are as follows:

[0019] Al in fused brown corundum 2 o 3 99.44wt%, CaO 0.03wt%, MgO 0.13wt%, Fe 2 o 3 0.01 wt%.

[0020] Al in white corundum 2 o 3 73.79wt%, CaO 1.00wt%, MgO 23.52wt%, SiO 2 0.93wt%, Fe 2 o 3 0.28 wt%.

[0021] Active α-Al 2 o 3 Middle Al 2 o 3 99.18wt%, CaO 0.02wt%, MgO 0.13wt%, SiO 2 0.05wt%, Fe 2 o 3 0.01 wt%.

[0022] The index of pure calcium aluminate cement is: Al 2 o 3 67.68wt%, CaO 28.45wt%, MgO 0.26wt%, SiO 2 0.12wt%, Fe 2 o 3 0.11 wt%.

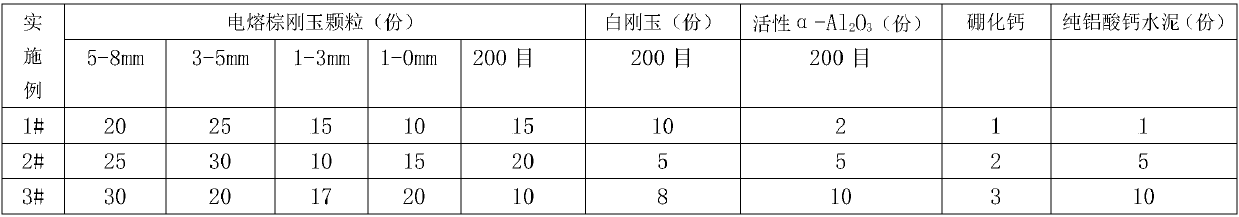

[0023] Embodiment sees table 1:

[0024] Table 1: Examples 1-3

[0025]

[0026] Aggregate crushing, screen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com