Wear and corrosion resistant castable prepared from bauxite-based homogenous material and preparation method thereof

A homogeneous material and castable technology, applied in the field of refractory castables, can solve the problems of poor wear resistance and alkali corrosion resistance, poor wear resistance and alkali corrosion resistance, low medium temperature strength, etc., and achieve high hot strength, low open pores, The effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The wear-resistant and anti-corrosion castable prepared by alumina-based homogeneous material is prepared according to the following ratio:

[0023] 70 Alumina-based homogeneous material with a particle size of 3-5mm 16%

[0024] (Al 2 o 3 content is 70%)

[0025] 70 Alumina-based homogeneous material with a particle size of 1-3mm 38%

[0026] 70 Alumina-based homogeneous material with a particle size of 0-1 mm 27%

[0027] Aluminum oxide powder 8%

[0028] Microsilica 6%

[0029] Pure calcium aluminate cement 5%

[0030] Admixture 0.3%

Embodiment 2

[0032] The wear-resistant and anti-corrosion castable prepared by alumina-based homogeneous material is prepared according to the following ratio:

[0033] 80 Alumina-based homogeneous material with a particle size of 3-5 mm 20%

[0034] (Al 2 o 3 content is 80%)

[0035] 80 Alumina-based homogeneous material with a particle size of 1-3 mm 30%

[0036] 80 Alumina-based homogeneous material with a particle size of 0-1mm 18%

[0037] Aluminum oxide powder 21%

[0038] Microsilica 5%

[0039] Pure calcium aluminate cement 6%

[0040] Admixture 0.235%

Embodiment 3

[0042] The wear-resistant and anti-corrosion castable prepared by alumina-based homogeneous material is prepared according to the following ratio:

[0043] 88 bauxite-based homogeneous material with a particle size of 5-8mm 12%

[0044] (Al 2 o 3 content is 88%)

[0045] 88 bauxite-based homogeneous material with a particle size of 3-5mm 12%

[0046] 88 bauxite-based homogeneous material with a particle size of 1-3mm 16%

[0047] 88 Alumina-based homogeneous material with a particle size of 0-1 mm 36%

[0048] Aluminum oxide powder 15%

[0049] Microsilica 4%

[0050] Pure calcium aluminate cement 5%

[0051] Admixture 0.43%

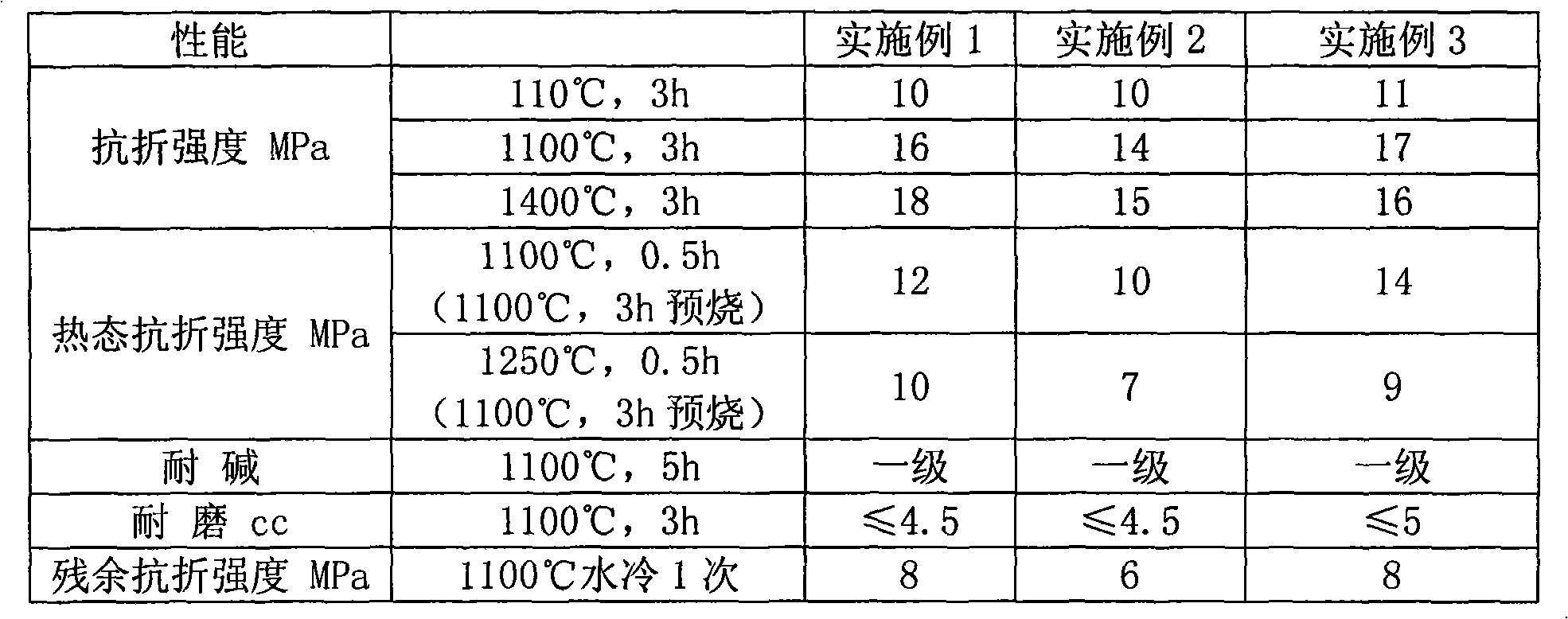

[0052] The properties of the wear-resistant and anti-erosion castables prepared by the present invention using alumina-based homogeneous materials are shown in the following table:

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com