Aluminum oxide-silicon carbide-carbon castable with high hot strength

An alumina and silicon carbide technology, which is applied in the field of alumina-silicon carbide-carbon castables, can solve the problems of low bonding strength, poor construction performance and high water content, and achieves improved thermal strength, enhanced direct bonding, volumetric good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

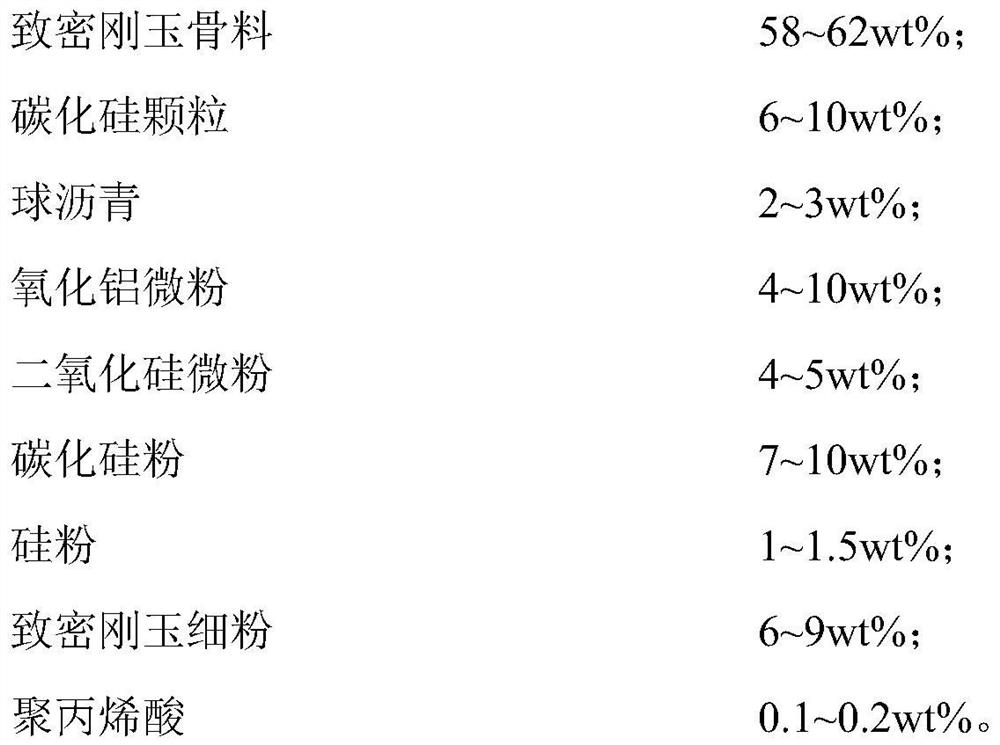

[0034] A high hot strength alumina-silicon carbide-carbon castable. The components and contents of the alumina-silicon carbide-carbon castable are:

[0035]

[0036] According to the components and contents of the alumina-silicon carbide-carbon castable, mix and mix; then add 3.2wt% water of the total mass of each component, stir evenly, vibrate and shape, dry naturally for 24 hours, at 110°C After heat treatment for 24 hours, an alumina-silicon carbide-carbon castable with high thermal strength is prepared.

[0037] The high thermal strength alumina-silicon carbide-carbon castable prepared in this example was tested for performance, and the results are shown in Table 1 (the test results are the average test results of 3 times, the same below).

[0038] Table 1 The performance test results of the alumina-silicon carbide-carbon castable with high thermal strength prepared in Example 1

[0039]

Embodiment 2

[0041] A high hot strength alumina-silicon carbide-carbon castable. The components and contents of the alumina-silicon carbide-carbon castable are:

[0042]

[0043] Mix according to the components and contents of the alumina-silicon carbide-carbon castable; add 3.1wt% water of the total mass of each component, stir evenly, vibrate and shape, dry naturally for 24 hours, at 110°C After heat treatment for 24 hours, an alumina-silicon carbide-carbon castable with high thermal strength is prepared.

[0044] The performance of the alumina-silicon carbide-carbon castable with high thermal strength prepared in this example was tested, and the results are shown in Table 2.

[0045] Table 2 The performance test results of the alumina-silicon carbide-carbon castable with high thermal strength prepared in Example 2

[0046]

Embodiment 3

[0048] A high hot strength alumina-silicon carbide-carbon castable. The components and contents of the alumina-silicon carbide-carbon castable are:

[0049]

[0050]Mix according to the components and contents of the alumina-silicon carbide-carbon castable; add 3.0wt% water of the total mass of each component, stir evenly, vibrate and shape, and dry naturally for 24 hours at 110°C After heat treatment for 24 hours, an alumina-silicon carbide-carbon castable with high thermal strength is prepared.

[0051] The performance test of the alumina-silicon carbide-carbon castable with high thermal strength prepared in this example is shown in Table 3.

[0052] Table 3 The performance test results of the alumina-silicon carbide-carbon castable with high thermal strength prepared in Example 3

[0053]

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com