Prefabricated part of coal injection pipe head

A technology of prefabricated parts and coal injection pipes, which is applied in the field of refractory materials, can solve the problems of harsh working environment of refractory materials, affecting the operation cycle of rotary kiln, and difficult control of castable performance, and achieves high thermal strength, convenient maintenance and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

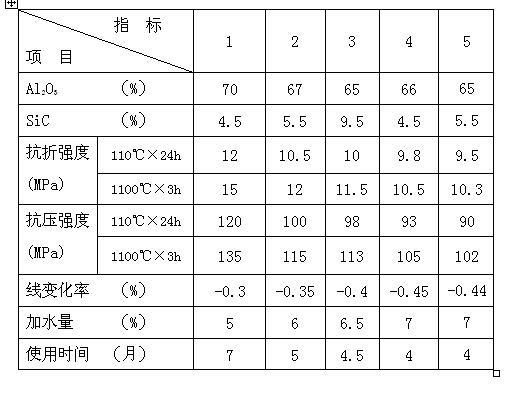

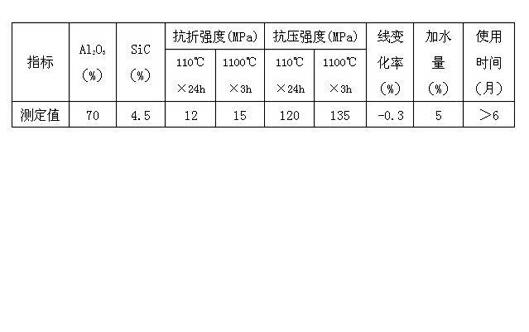

Embodiment 1

[0032] Example 1, the prefabricated part of the coal injection pipe head, 25 parts of 5-3mm sintered mullite, 28 parts of 3-1mm sintered mullite, 12 parts of 1-0mm sintered mullite, 8 parts of white corundum, 5 parts Silicon carbide, 5 parts of sillimanite, 5 parts of α-alumina micropowder, 4 parts of silicon micropowder, 8 parts of pure calcium aluminate cement, 0.15 part of water reducing agent, 5 parts of water are mixed and stirred evenly, vibrating pouring, after conventional curing and baking use.

Embodiment 2

[0033] Example 2, the prefabricated part of the coal injection pipe head, 28 parts of 5-3mm sintered mullite, 21 parts of 3-1mm sintered mullite, 18 parts of 1-0mm sintered mullite, 5 parts of white corundum, 6 parts Silicon carbide, 5 parts of sillimanite, 6 parts of α-alumina micropowder, 5 parts of silicon micropowder, 6 parts of pure calcium aluminate cement, 0.2 part of water reducer, 6 parts of water are mixed and stirred evenly, vibrating pouring, after conventional curing and baking use.

Embodiment 3

[0034] Example 3, the prefabricated part of the coal injection pipe head, 29 parts of 5-3mm sintered mullite, 22 parts of 3-1mm sintered mullite, 14 parts of 1-0mm sintered mullite, 6 parts of white corundum, 10 parts Silicon carbide, 6 parts of sillimanite, 5 parts of α-alumina micropowder, 4 parts of silicon micropowder, 4 parts of pure calcium aluminate cement, 0.2 part of water reducing agent, 6.5 parts of water are mixed and stirred evenly, vibrating pouring, after conventional curing and baking use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com