Solid waste pelletizing process and efficient sintering method thereof

A sintering method and pelletizing technology, which is applied in the sintering process of the metallurgical industry and the field of solid waste recycling, can solve the problems of solid waste fuel consumption, unfavorable sinter iron grade, and emission problems that cannot significantly improve sintering productivity, so as to avoid decomposition Problems of heat consumption and CO2 emission, improvement of sintering production quality index, effect of sintering with low CO2 emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

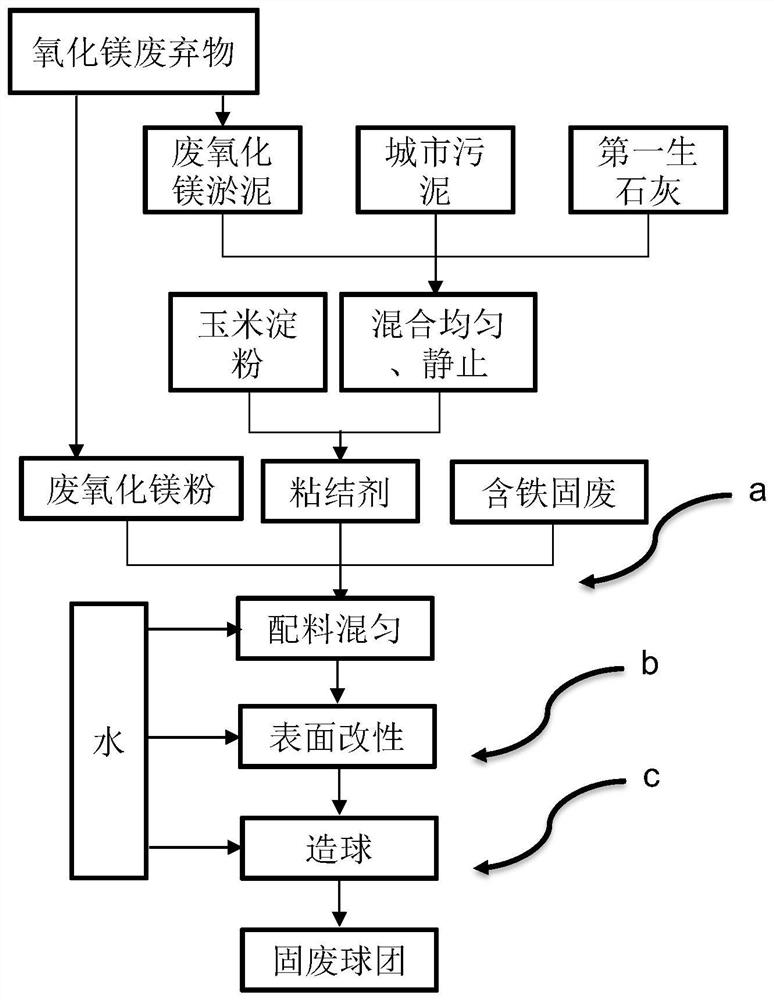

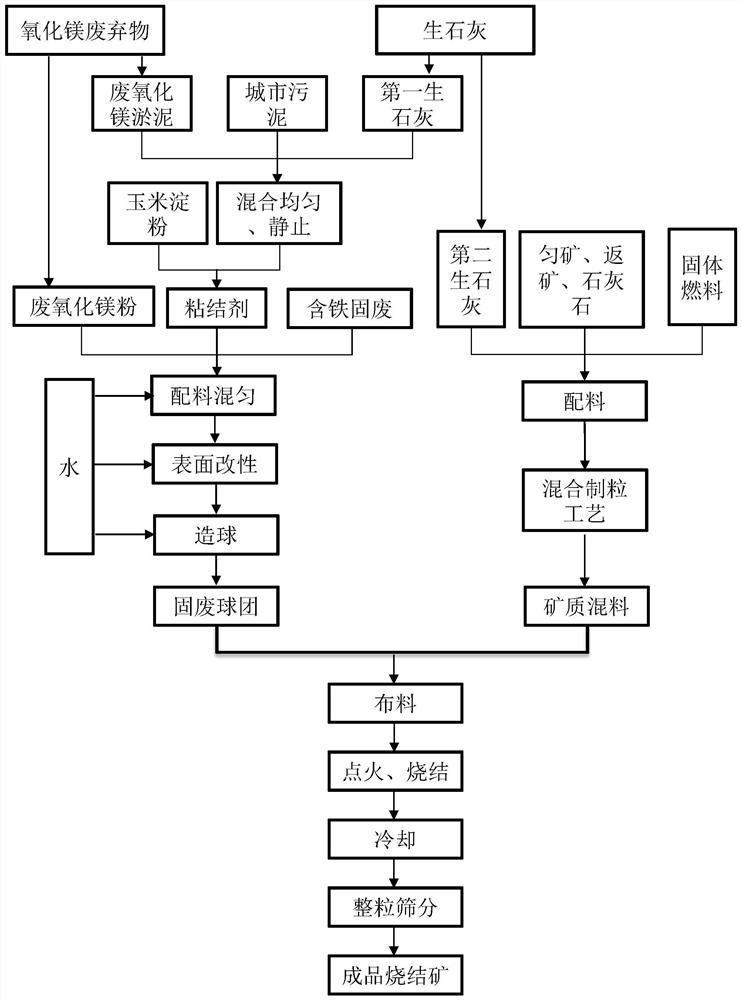

[0056] The waste magnesia sludge, waste magnesia powder, municipal sludge and iron-containing solid waste in the present embodiment are processed in the following ways:

[0057] (1) Preparation of binder: After the waste magnesia sludge, municipal sludge and the first quicklime are mixed uniformly according to the mass ratio of 1:1:8, they are placed for 10 minutes, and then mixed with corn starch in a mass ratio of 2:1. After the second strong mixing, the binder is obtained after mixing evenly;

[0058] (2) Preparation of solid waste pellets: 3wt% of waste magnesium oxide powder and 97wt% of iron-containing solid waste are added to a strong mixer as solid waste raw materials, mixed with the binder prepared in this example, and added with water After intensive mixing, the solid waste mixture is obtained, in which the binder accounts for 0.5wt% of the dry mass of the solid waste raw material; and then the surface modification treatment of the grinding mill is carried out to mak...

Embodiment 2

[0062] The waste magnesia sludge, waste magnesia powder, municipal sludge and iron-containing solid waste in the present embodiment are processed in the following ways:

[0063] (1) Preparation of binder: After the waste magnesia sludge, municipal sludge and the first quicklime are mixed uniformly according to the mass ratio of 1:2:10, they are placed for 30 minutes, and then mixed with corn starch in a mass ratio of 4:1. After the second strong mixing, the binder is obtained after mixing evenly;

[0064] (2) Preparation of solid waste pellets: 8wt% of waste magnesium oxide powder and 92wt% of iron-containing solid waste are added to a strong mixer as solid waste raw materials, mixed with the binder prepared in this example, and added with water After intensive mixing, the solid waste mixture is obtained, in which the binder accounts for 2.0wt% of the dry weight of the solid waste raw material; and then the surface modification treatment of the grinding mill is carried out to ...

Embodiment 3

[0068] The waste magnesia sludge, waste magnesia powder, municipal sludge and iron-containing solid waste in the present embodiment are processed in the following ways:

[0069] (1) Preparation of the binder: After the waste magnesia sludge, municipal sludge and the first quicklime are mixed uniformly according to the mass ratio of 1:2:9, they are placed for 20 minutes, and then mixed with corn starch in a mass ratio of 3:1. After the second strong mixing, the binder is obtained after mixing evenly;

[0070] (2) Preparation of solid waste pellets: 5wt% of waste magnesium oxide powder and 95wt% of iron-containing solid waste are added to a strong mixer as solid waste raw materials, mixed with the binder prepared in this example, and added with water After intensive mixing, a solid waste mixture is obtained, in which the binder accounts for 1.0wt% of the dry weight of the solid waste raw material; and then the surface modification treatment of the grinding mill is carried out to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com