Patents

Literature

30results about How to "Low cost recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

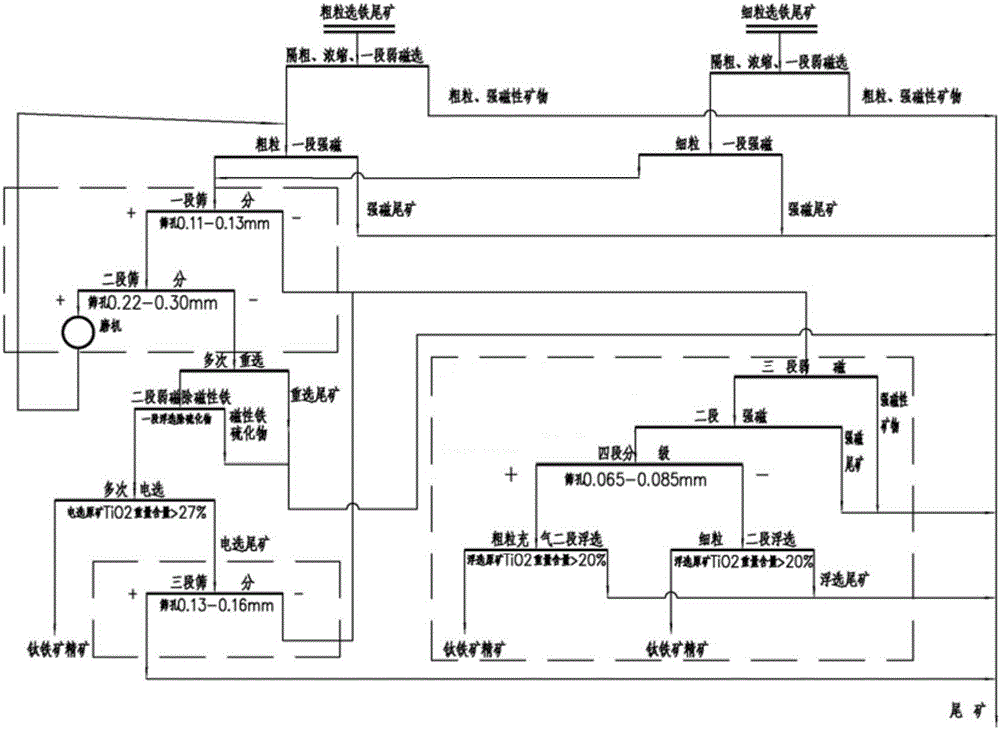

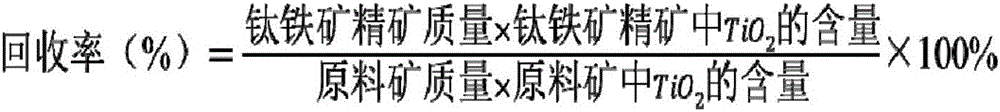

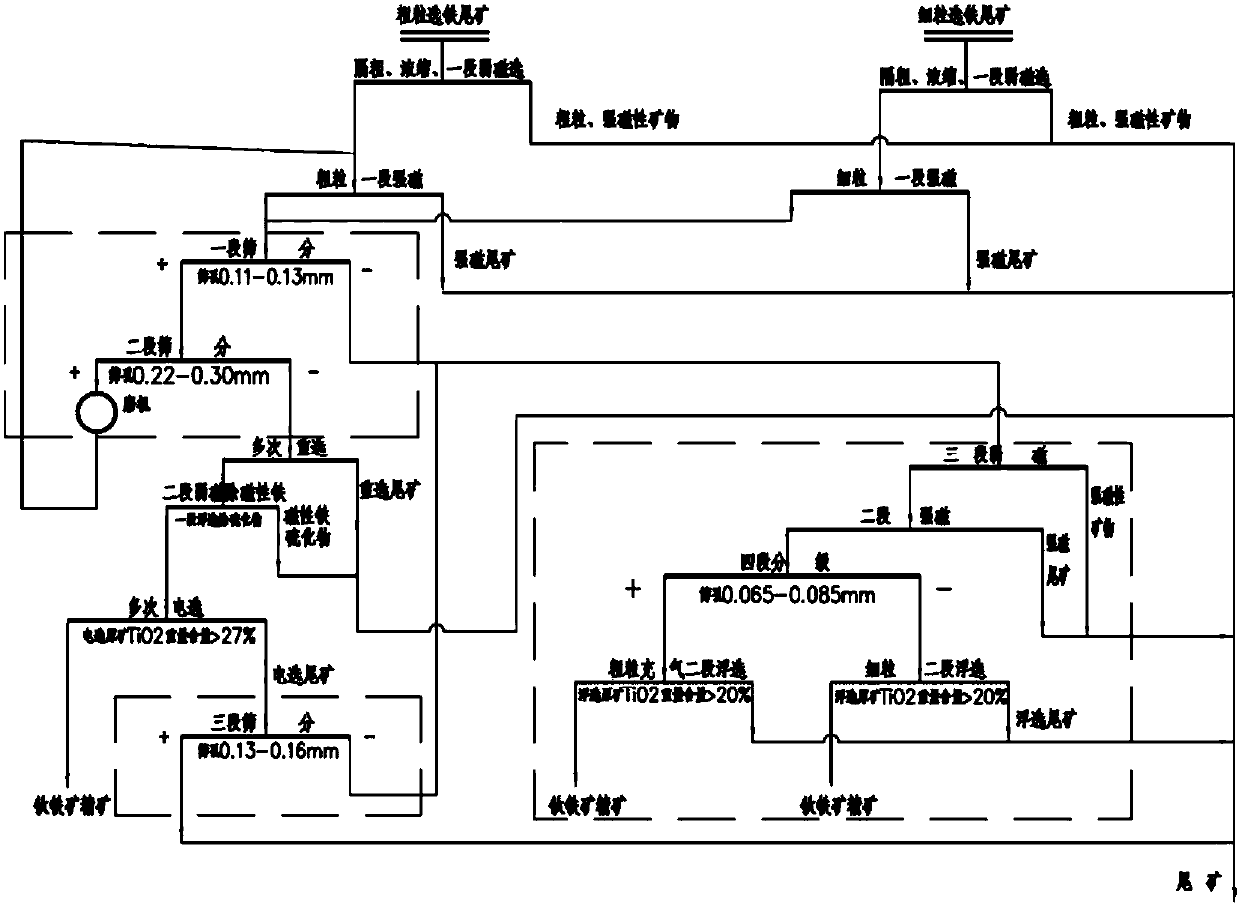

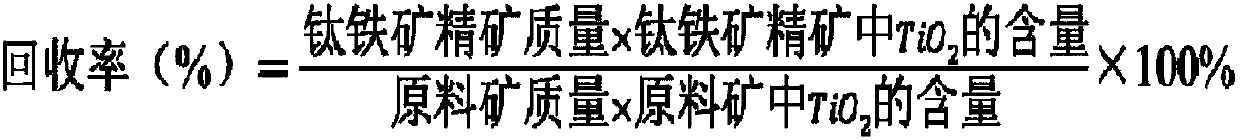

Method for recycling ilmenite from vanadium titano-magnetite iron dressing tailings

ActiveCN106179720AOvercome costsHigh recovery rateMechanical material recoveryWet separationMagnetiteClassification methods

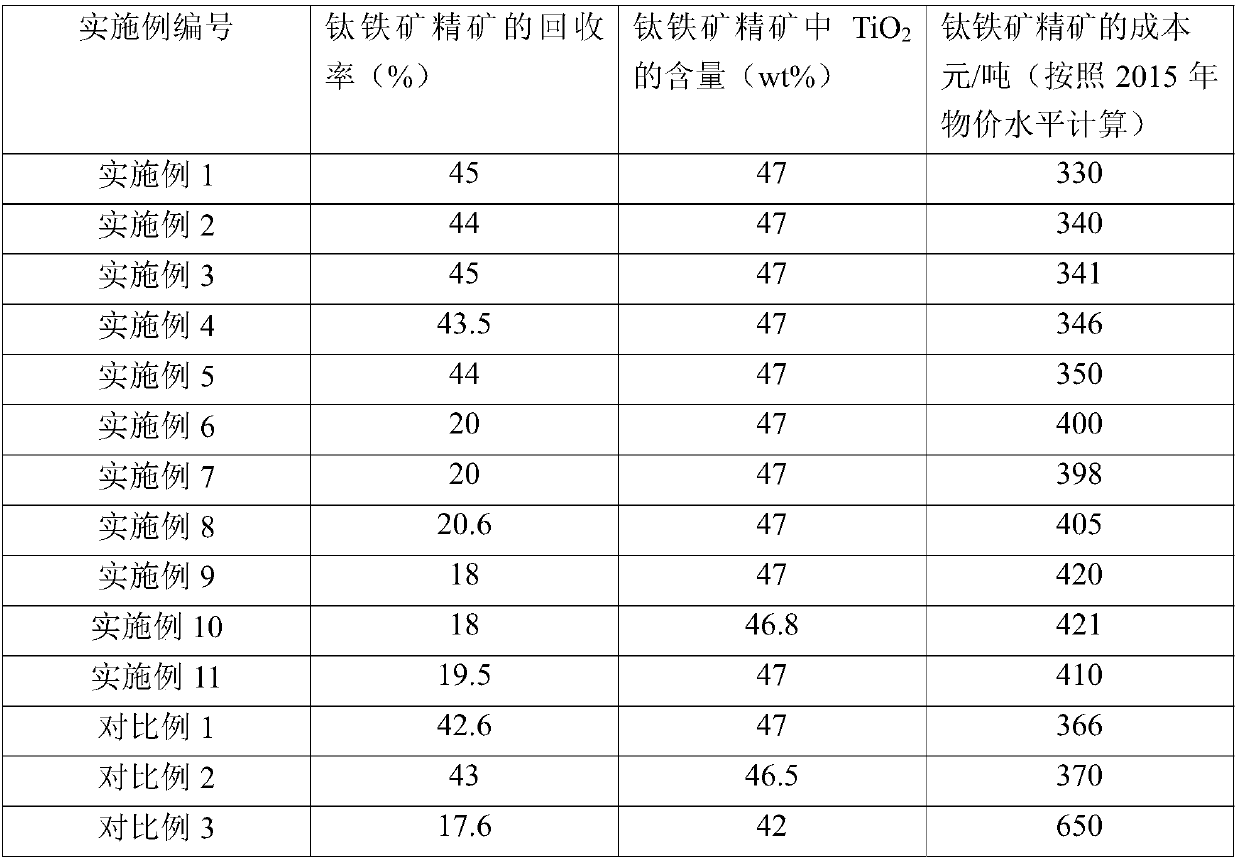

The invention discloses a method for recycling ilmenite from vanadium titano-magnetite iron dressing tailings. The method comprises the steps that the specific susceptibility of main gangue in the iron dressing tailings, the specific susceptibility of the ilmenite in the iron dressing tailings and the content of TiO2 in the iron dressing tailings are determined; when the iron dressing tailings meet the condition 1, the iron dressing tailings are subjected to first-section strong magnetic separation, first-section strong magnetism concentrates are subjected to one-time or multi-time reselection, and gravity concentrates are obtained; the gravity concentrates are subjected to first-time flotation and one-time or multi-time electric separation, and ilmenite concentrates are obtained, wherein the condition 1 can be shown in the formula: X1>(X2*60%), the total amount of the iron dressing tailings serves as a standard, the content of the TiO2 in the iron dressing tailings is lower than 5 wt%, X1 is the specific susceptibility value of the main gangue in the iron dressing tailings, and X2 is the specific susceptibility value of the ilmenite in the iron dressing tailings; and otherwise, the iron dressing tailings are subjected to a strict granularity classification method. By mean of the method, the production cost of the ilmenite is reduced, and the grade of the TiO2 of selected raw ore obtained after electric separation and flotation is improved.

Owner:PANGANG GRP MINING

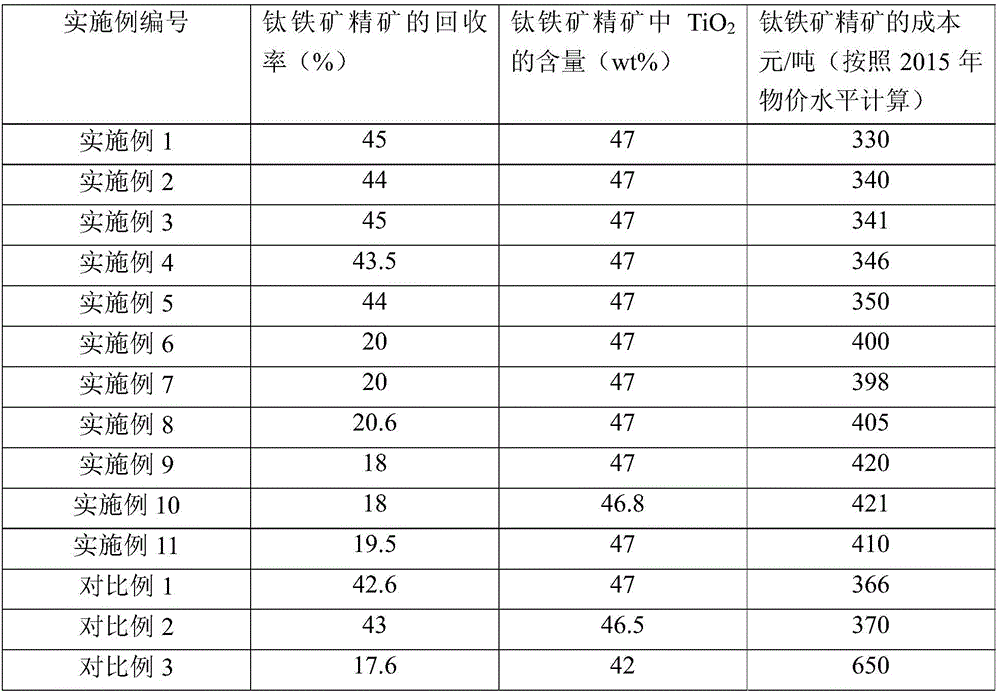

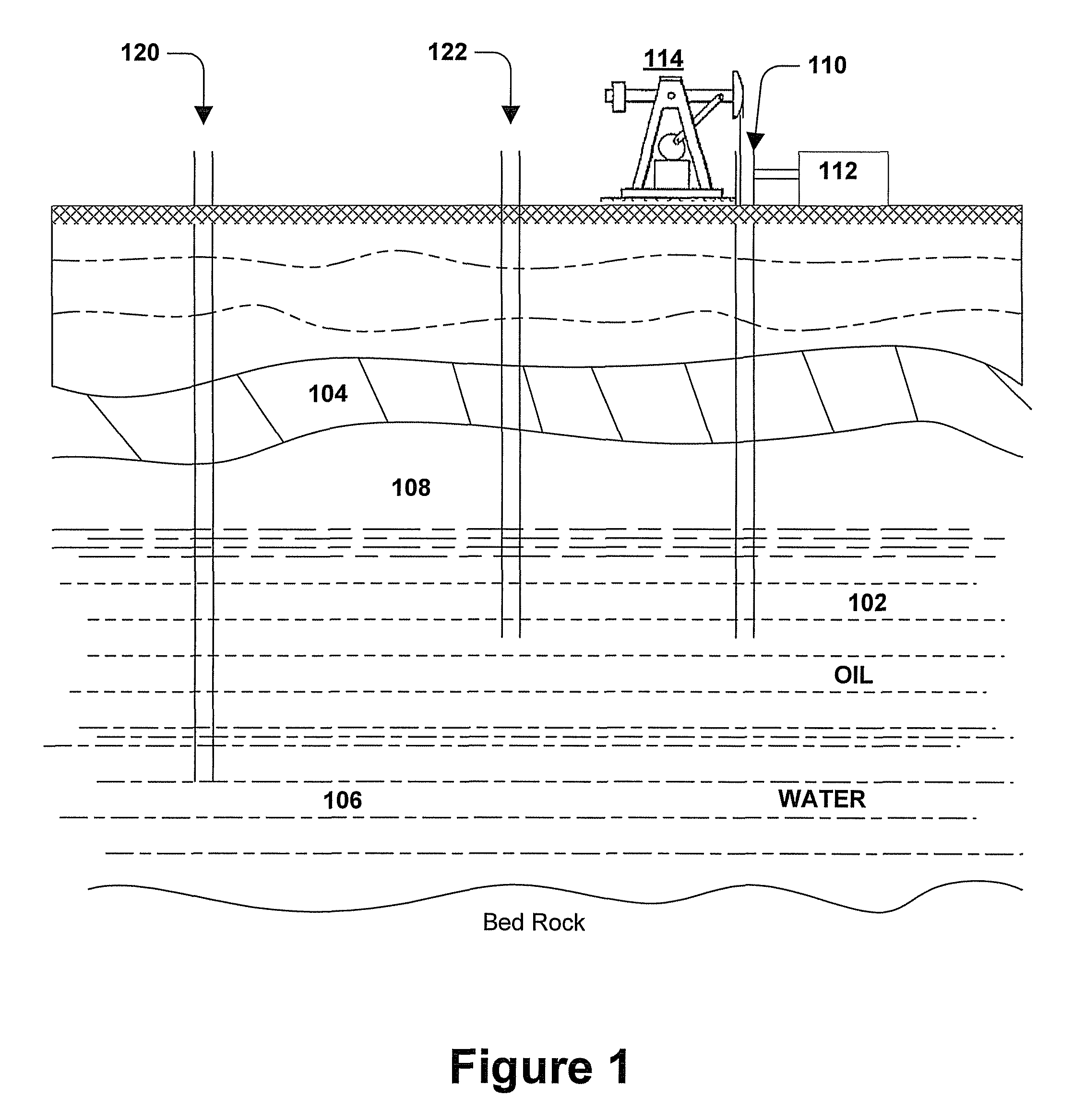

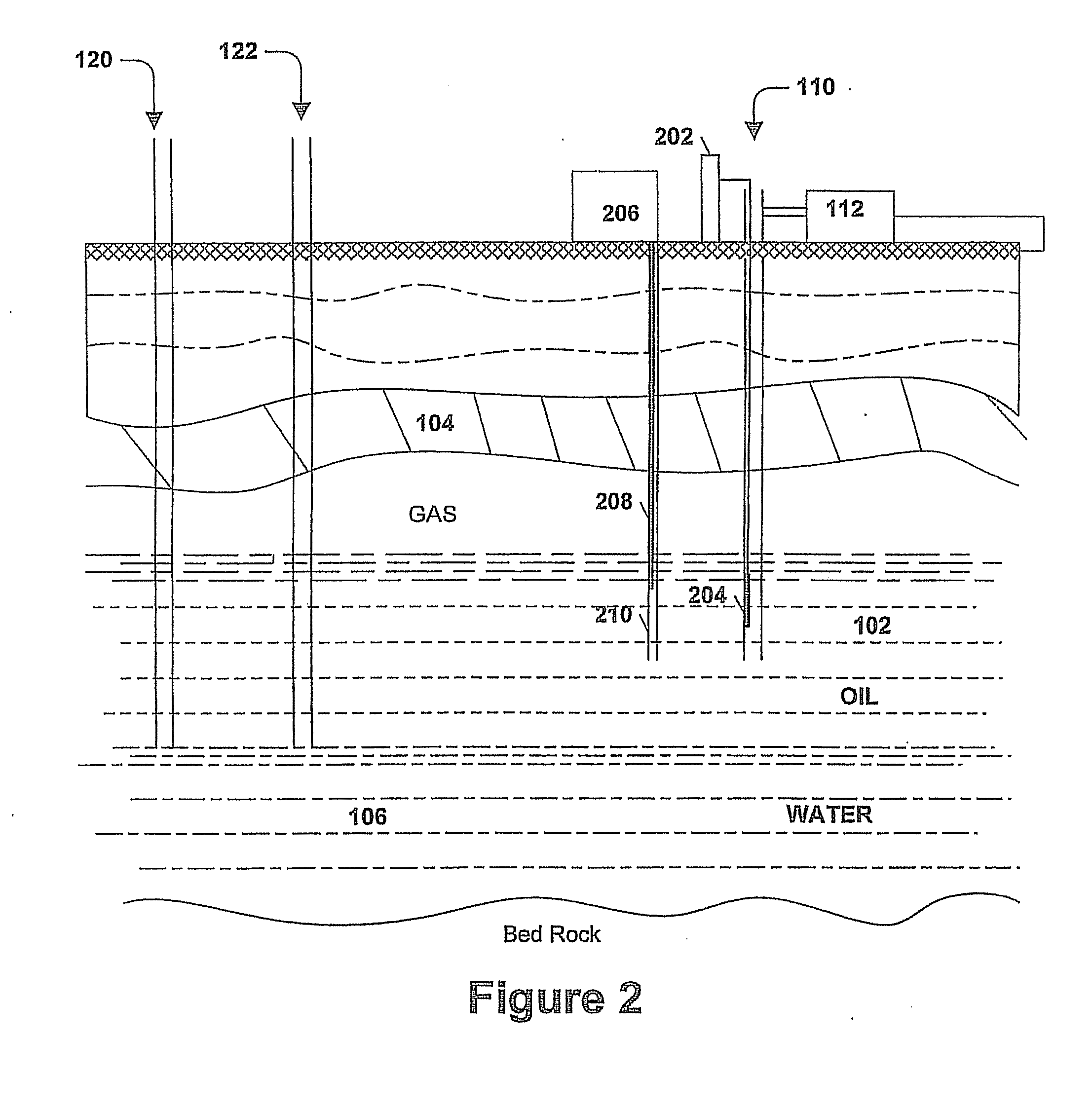

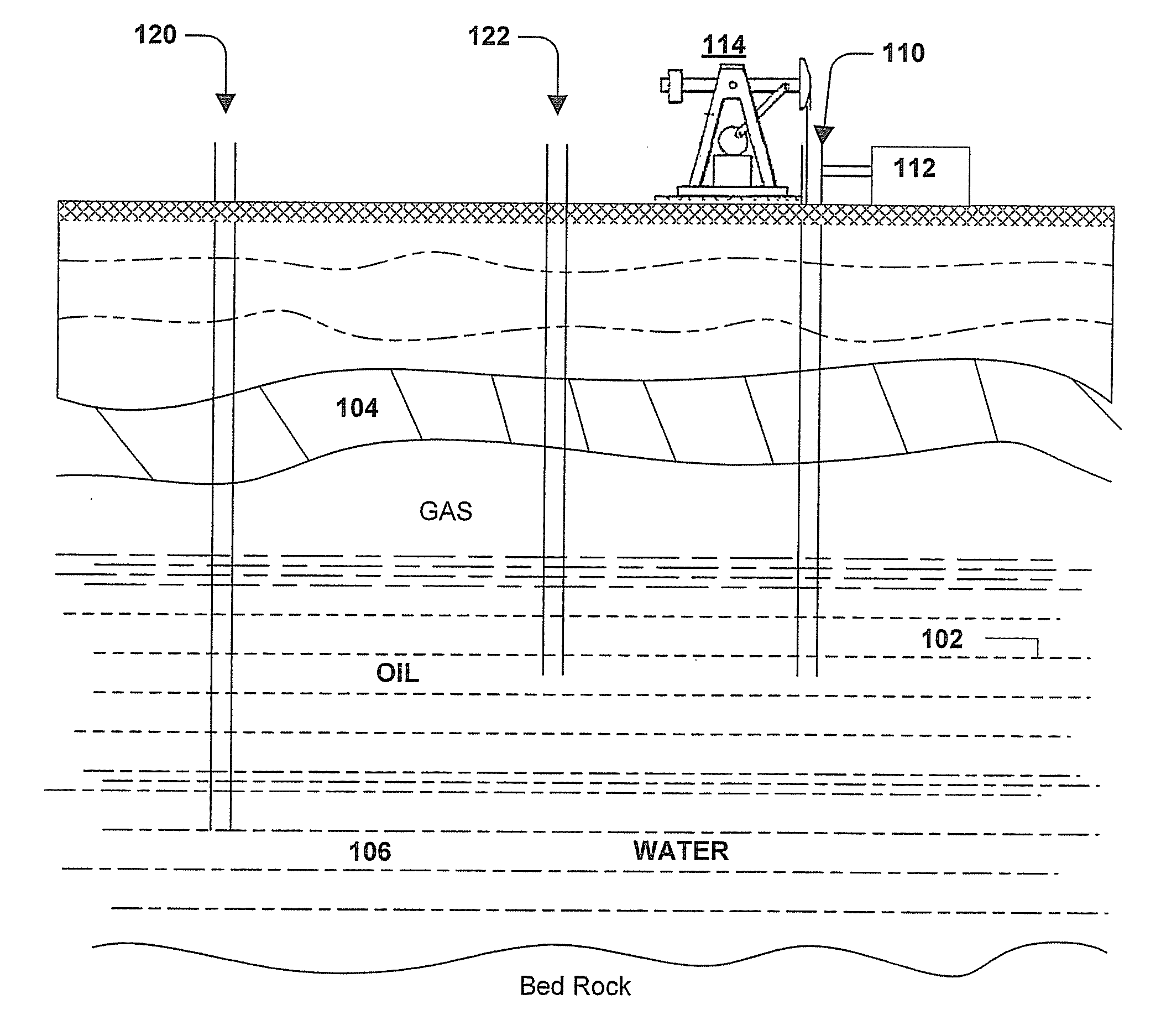

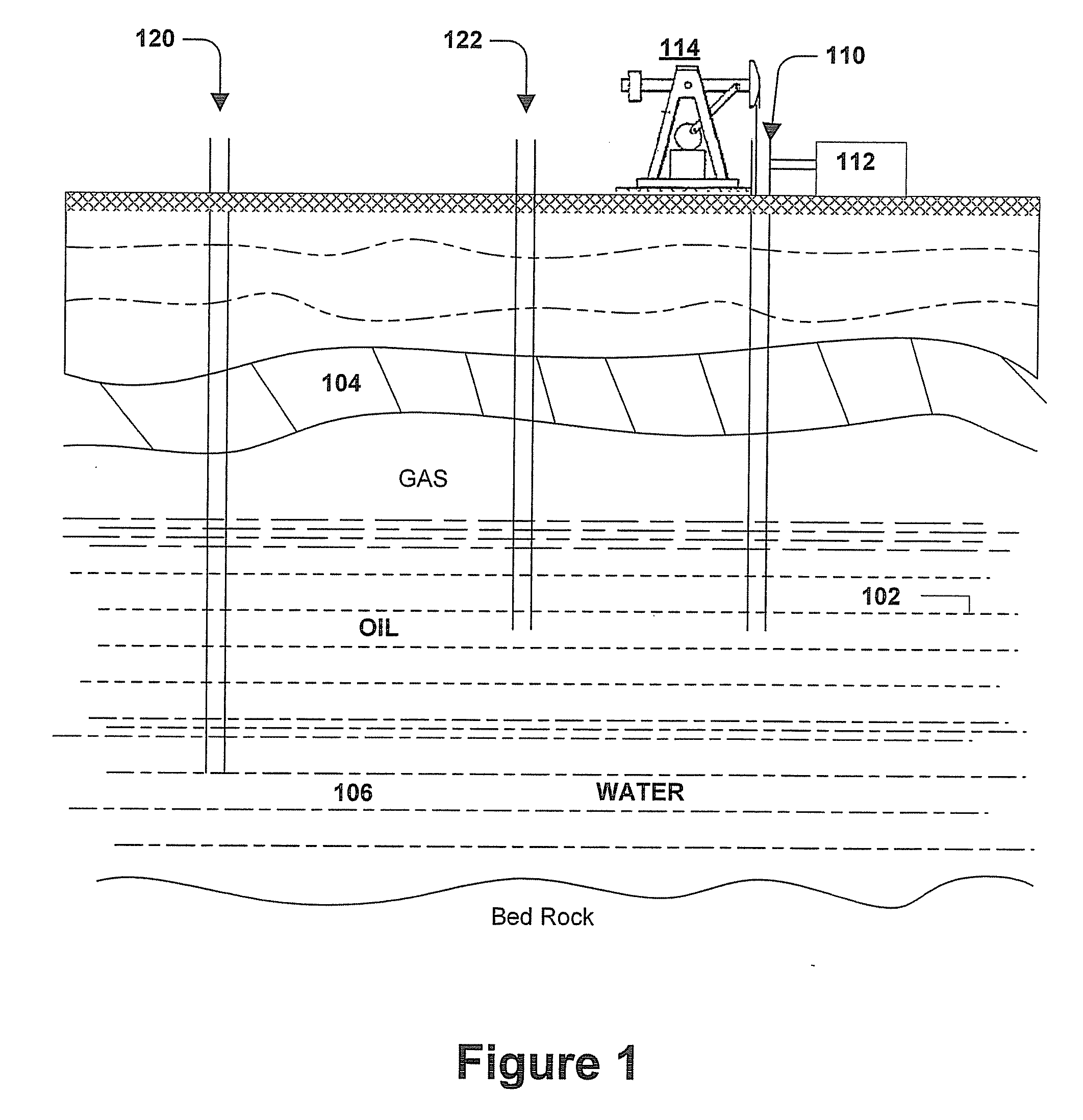

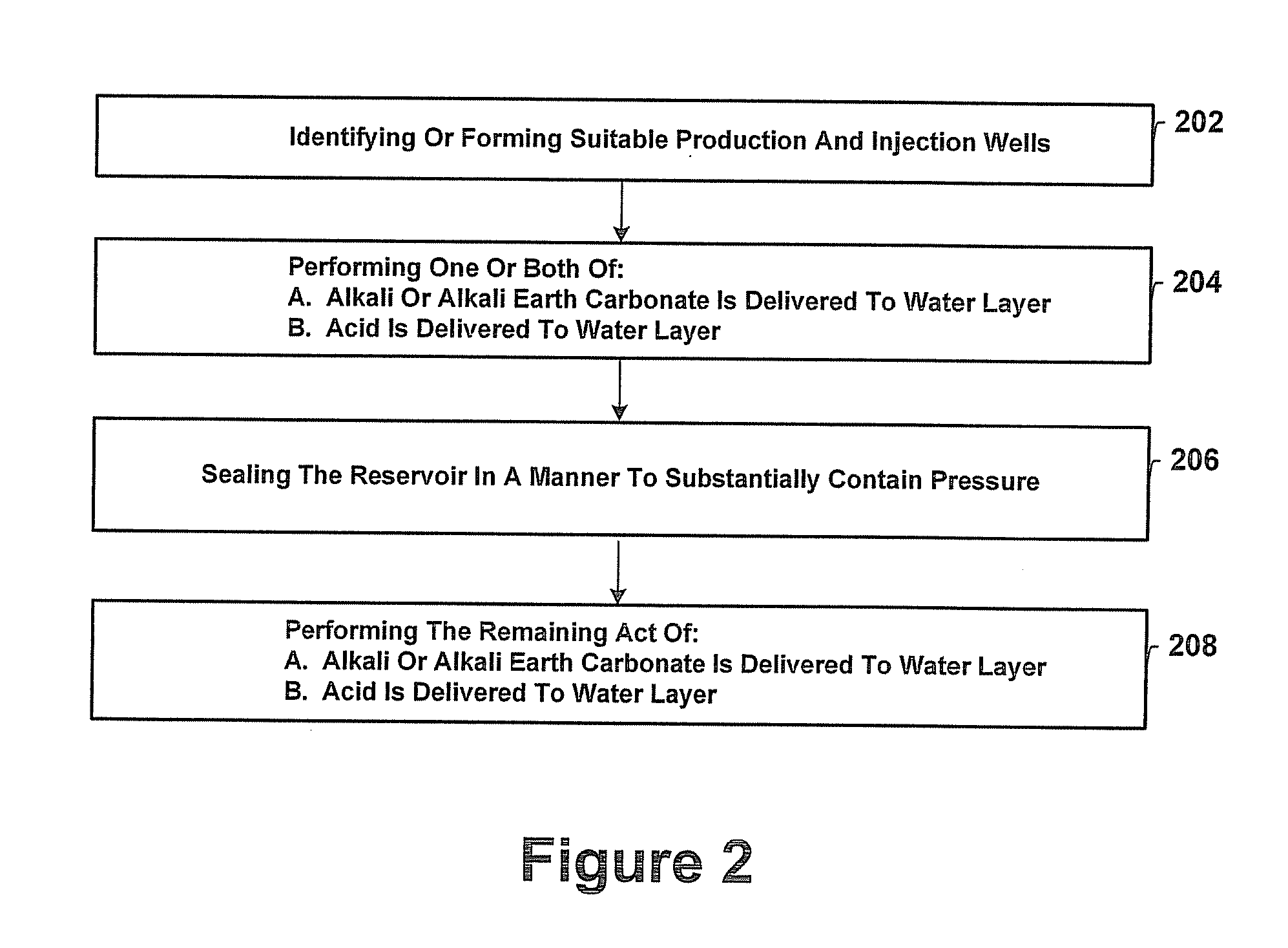

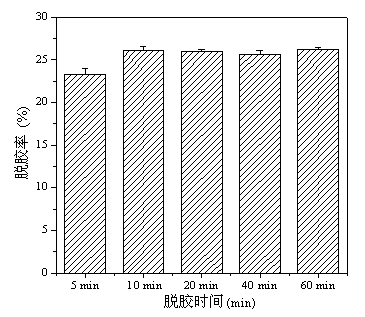

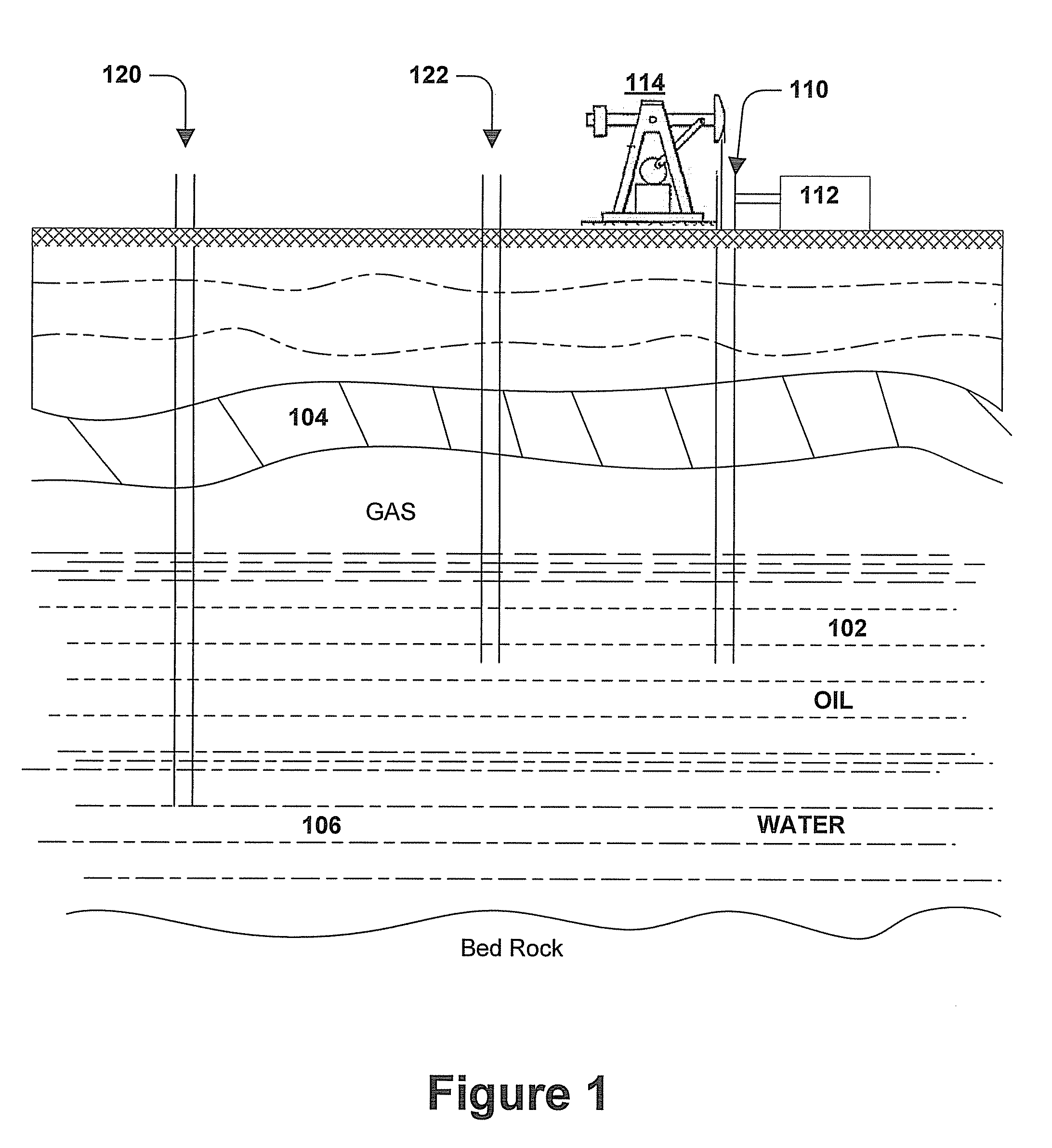

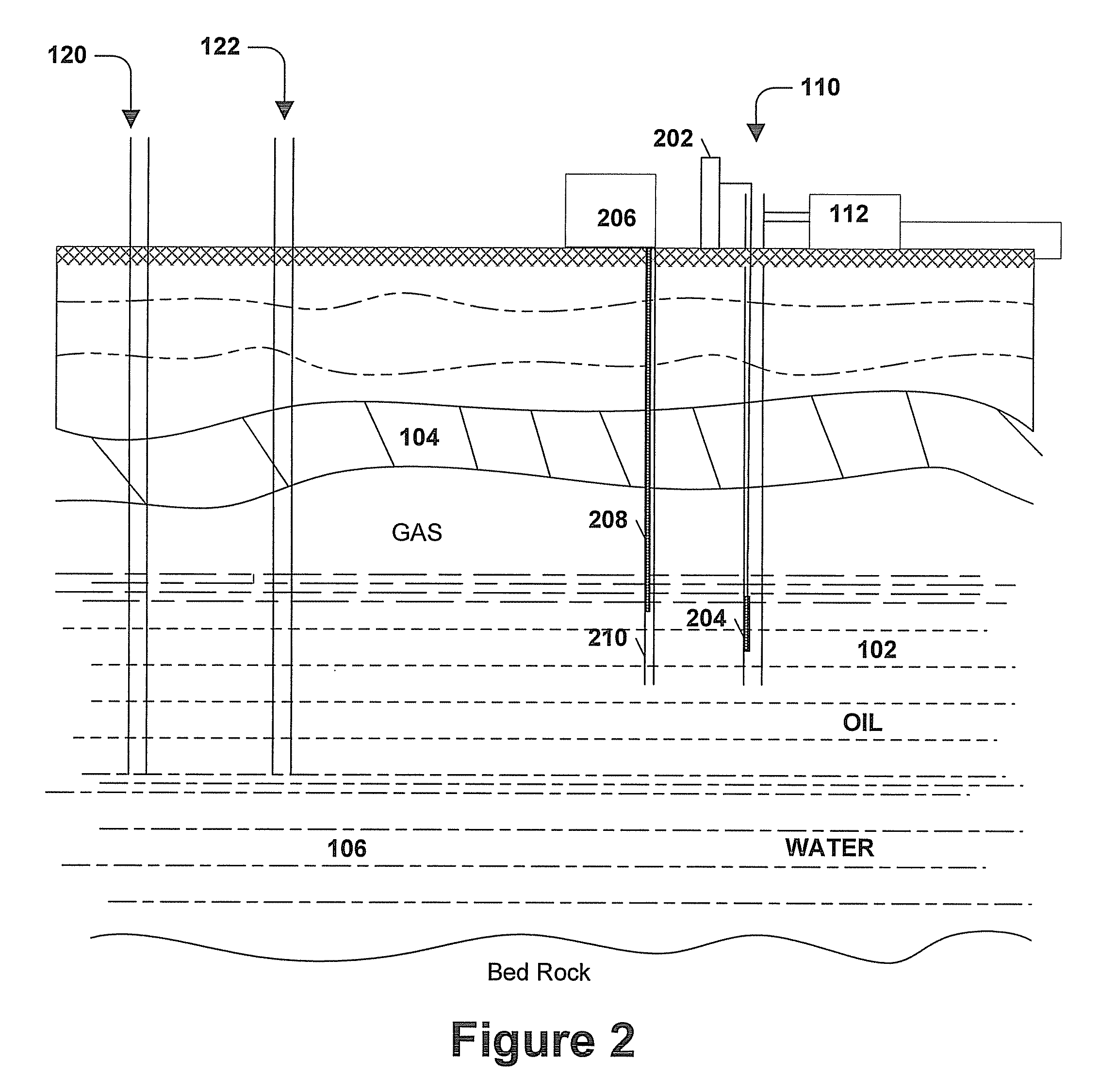

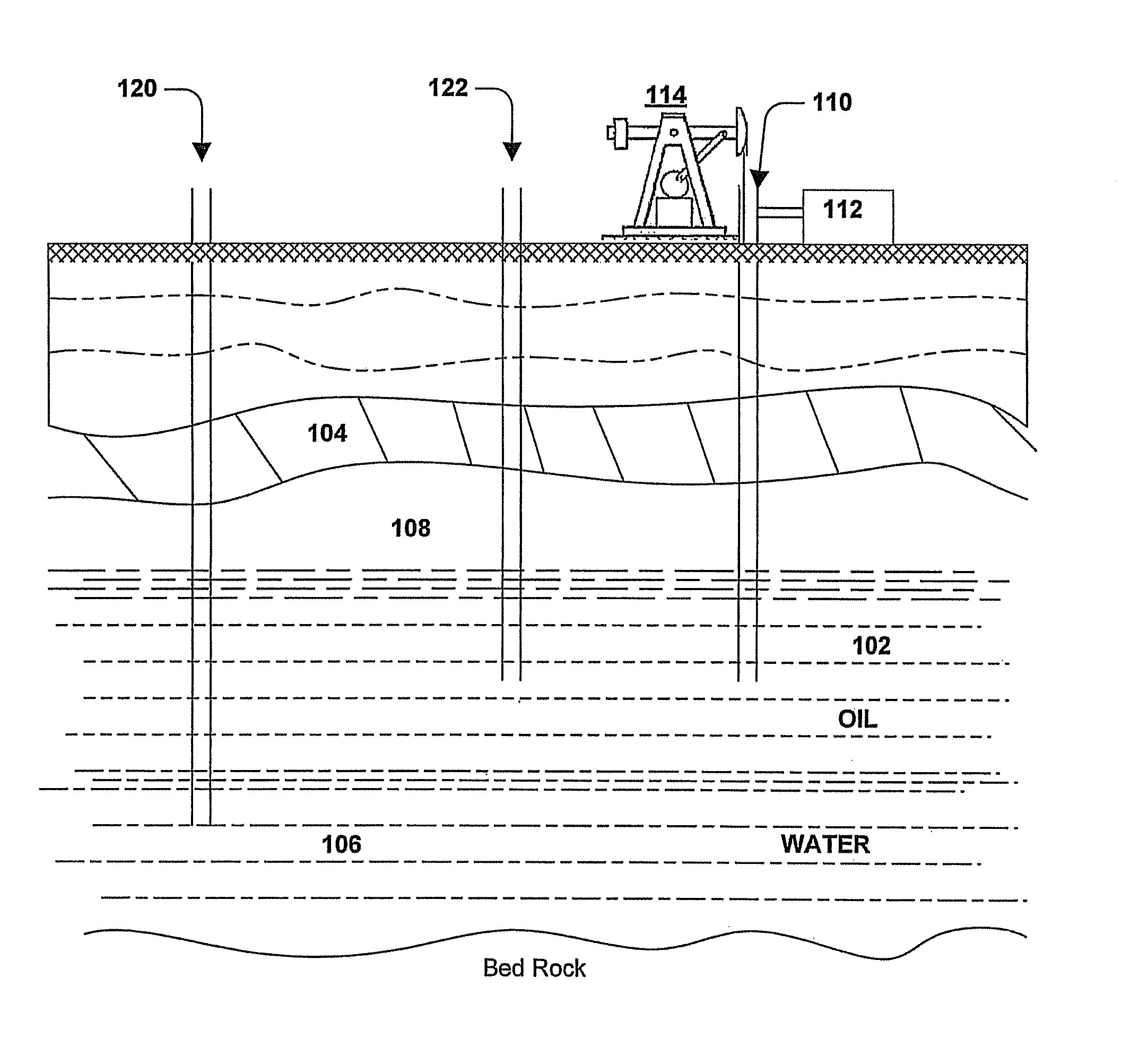

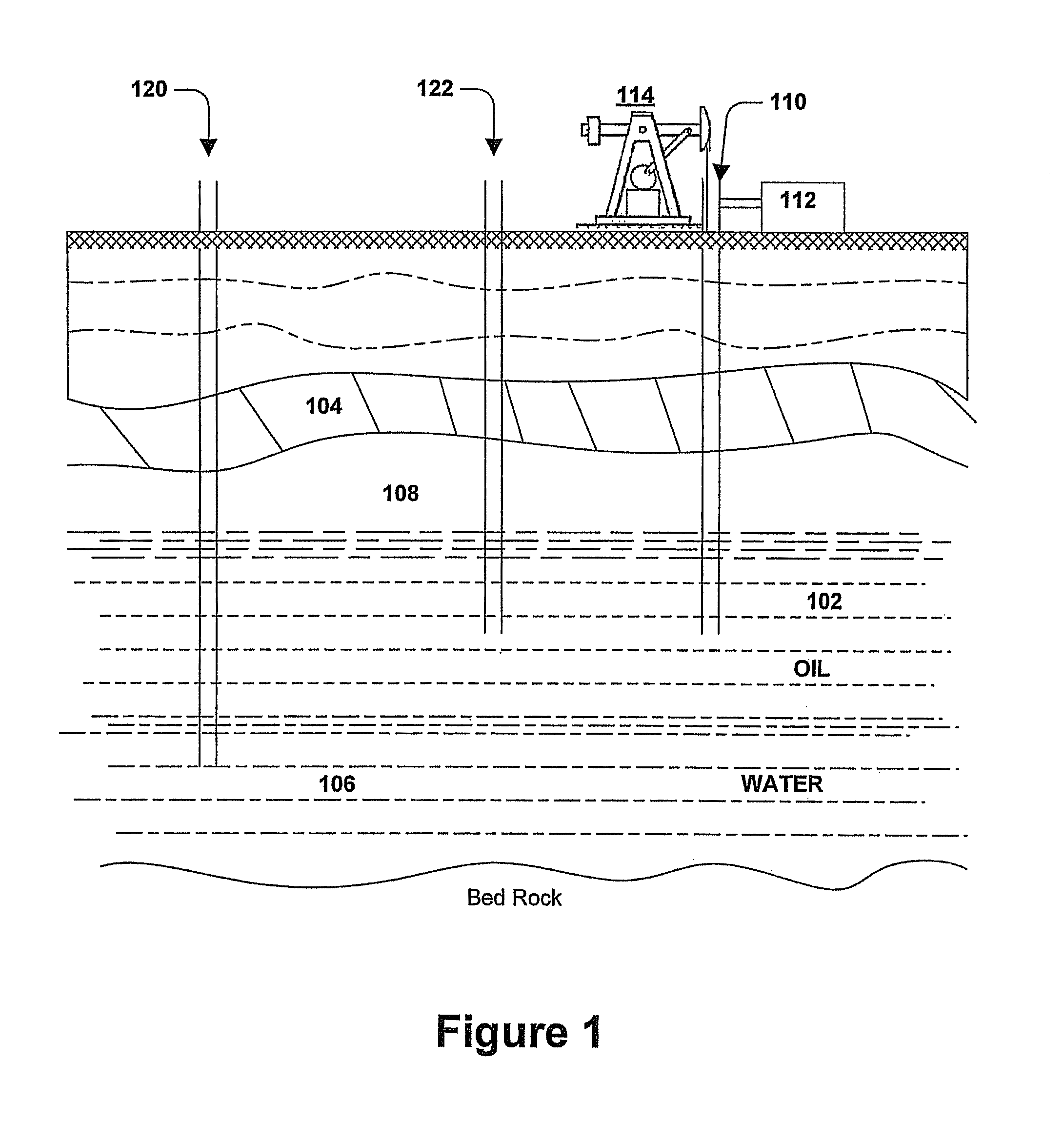

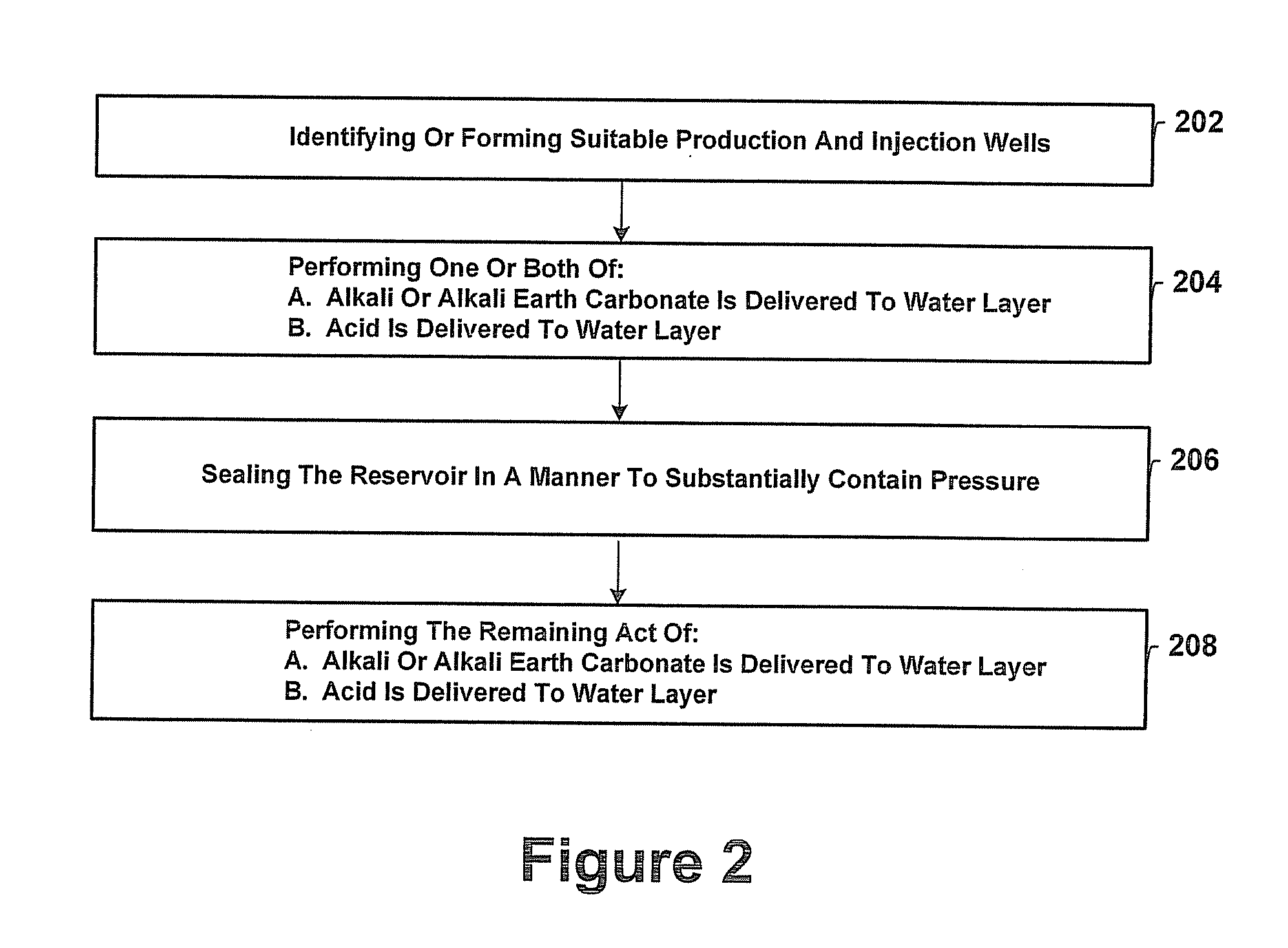

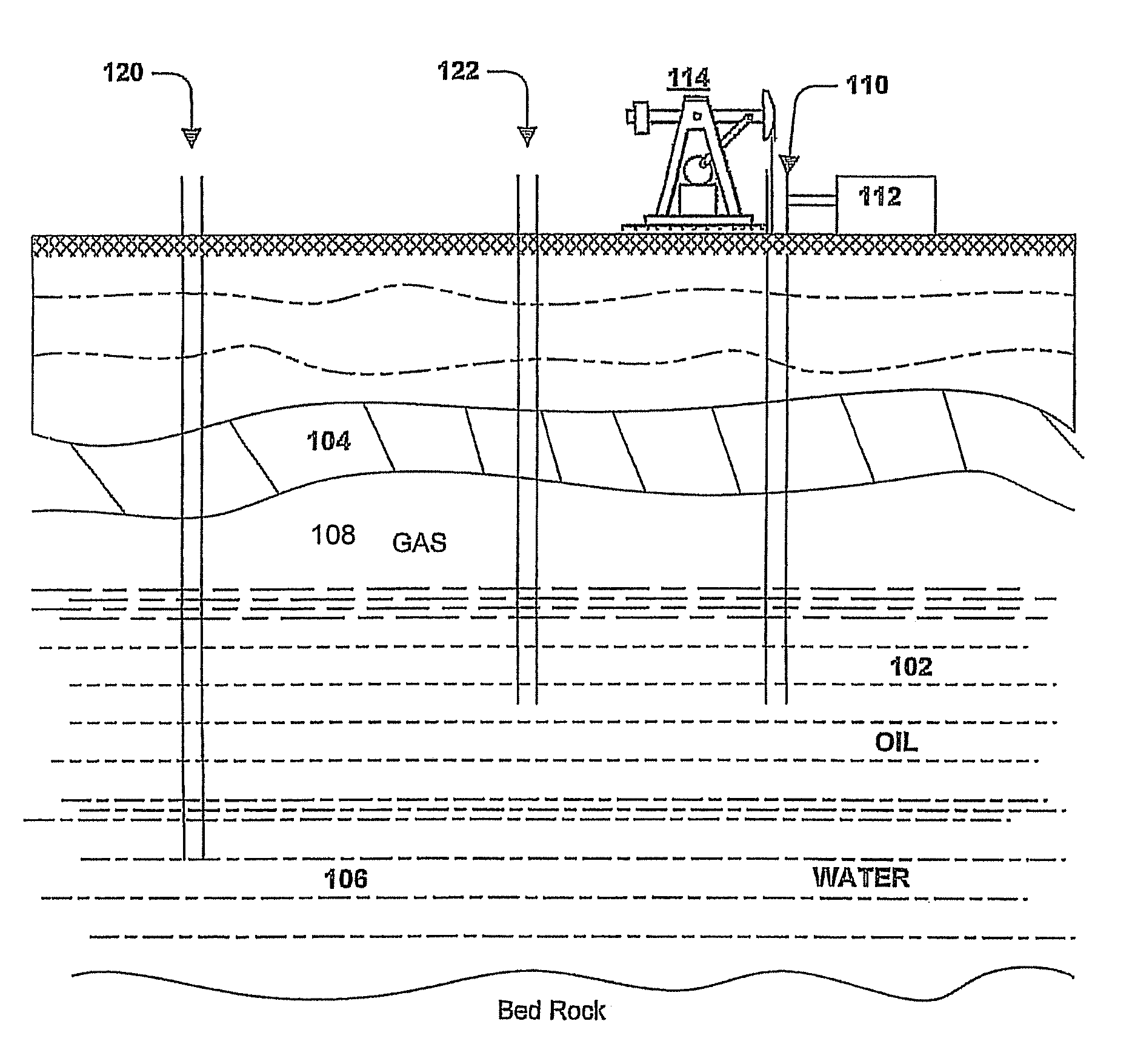

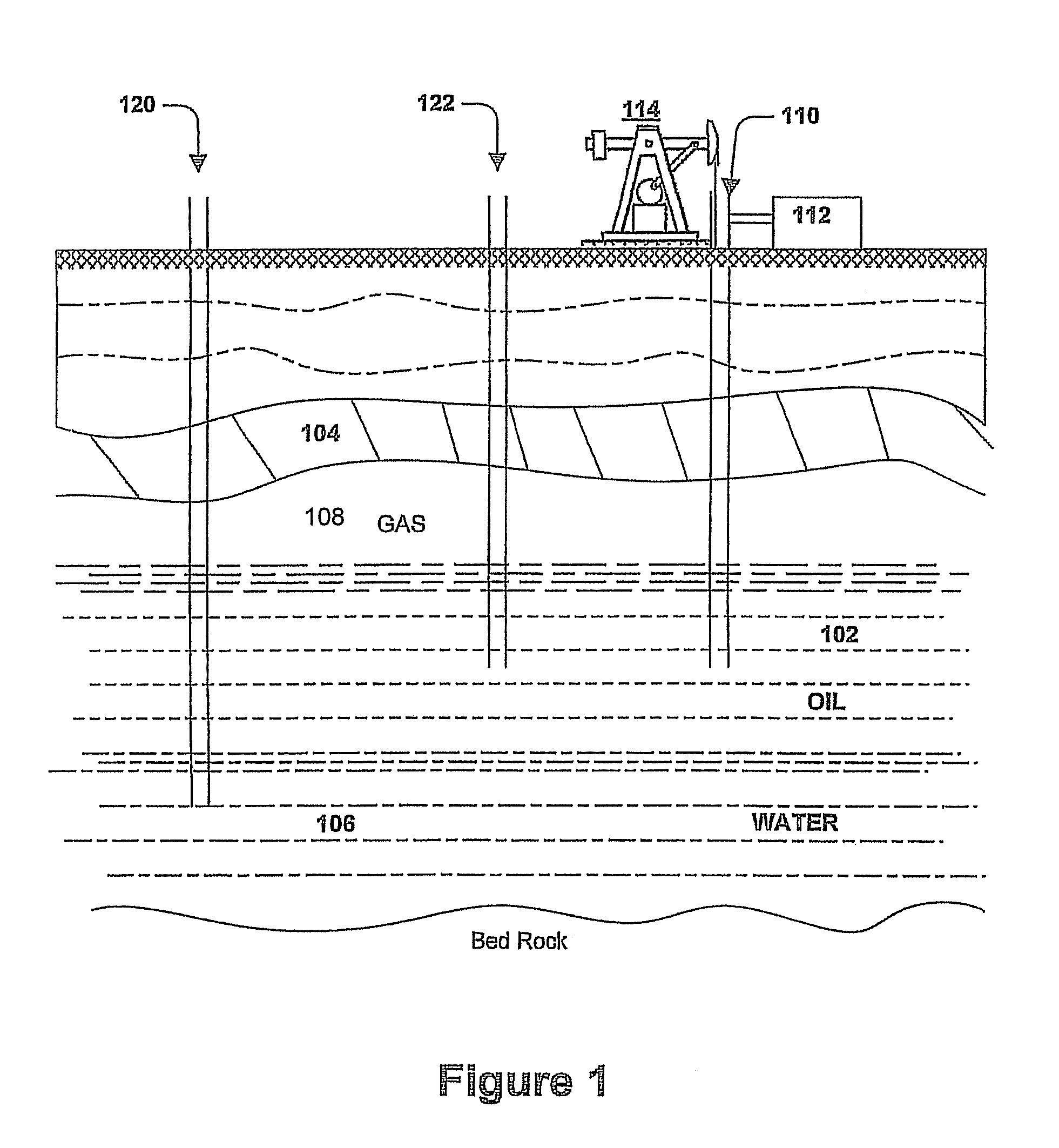

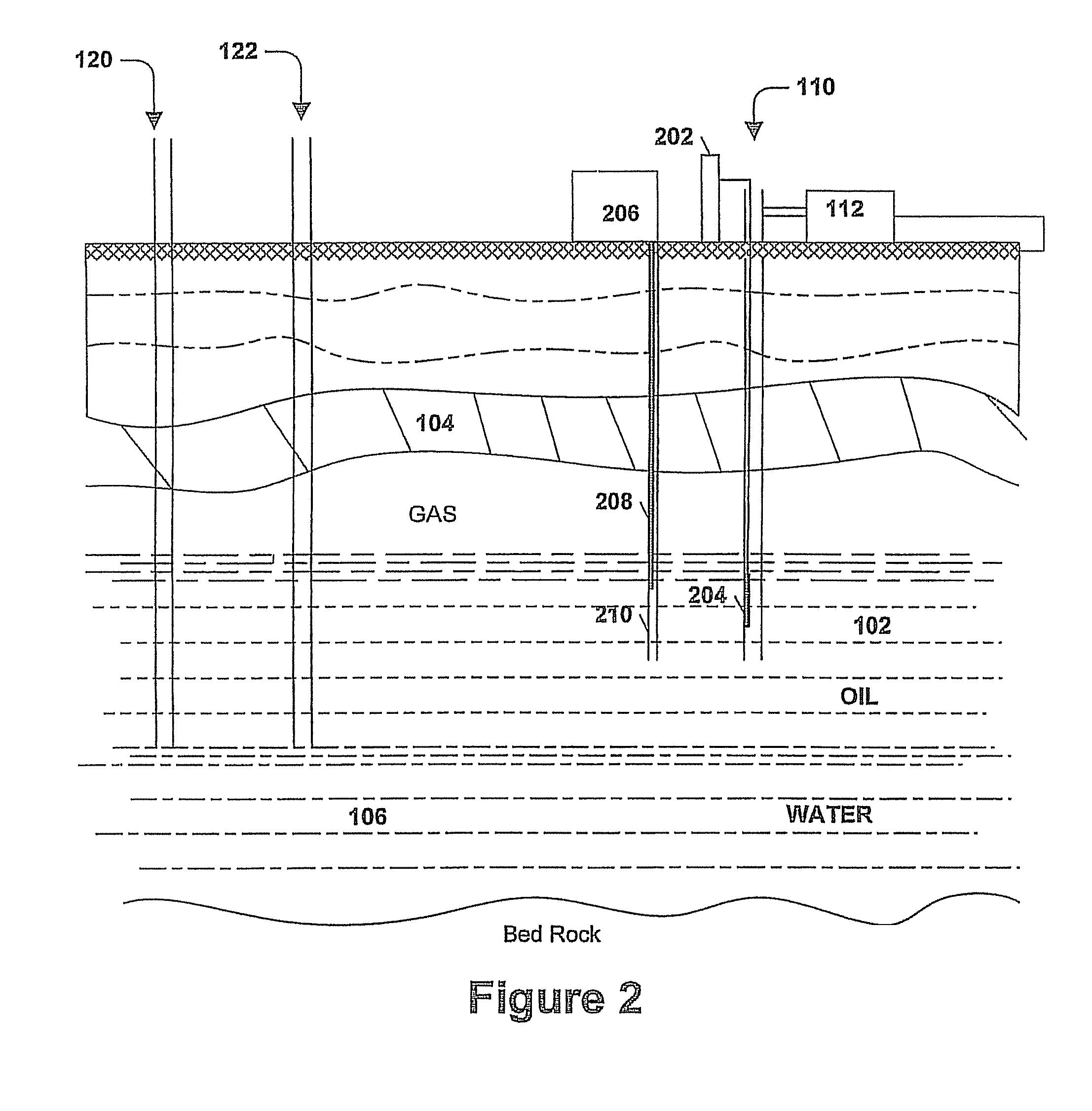

Methods for increasing oil production

InactiveUS8132628B2Low cost recyclingIncrease oil productionOther gas emission reduction technologiesFluid removalAlkaline earth metalOil production

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir.

Owner:YANG DUCK JOO +1

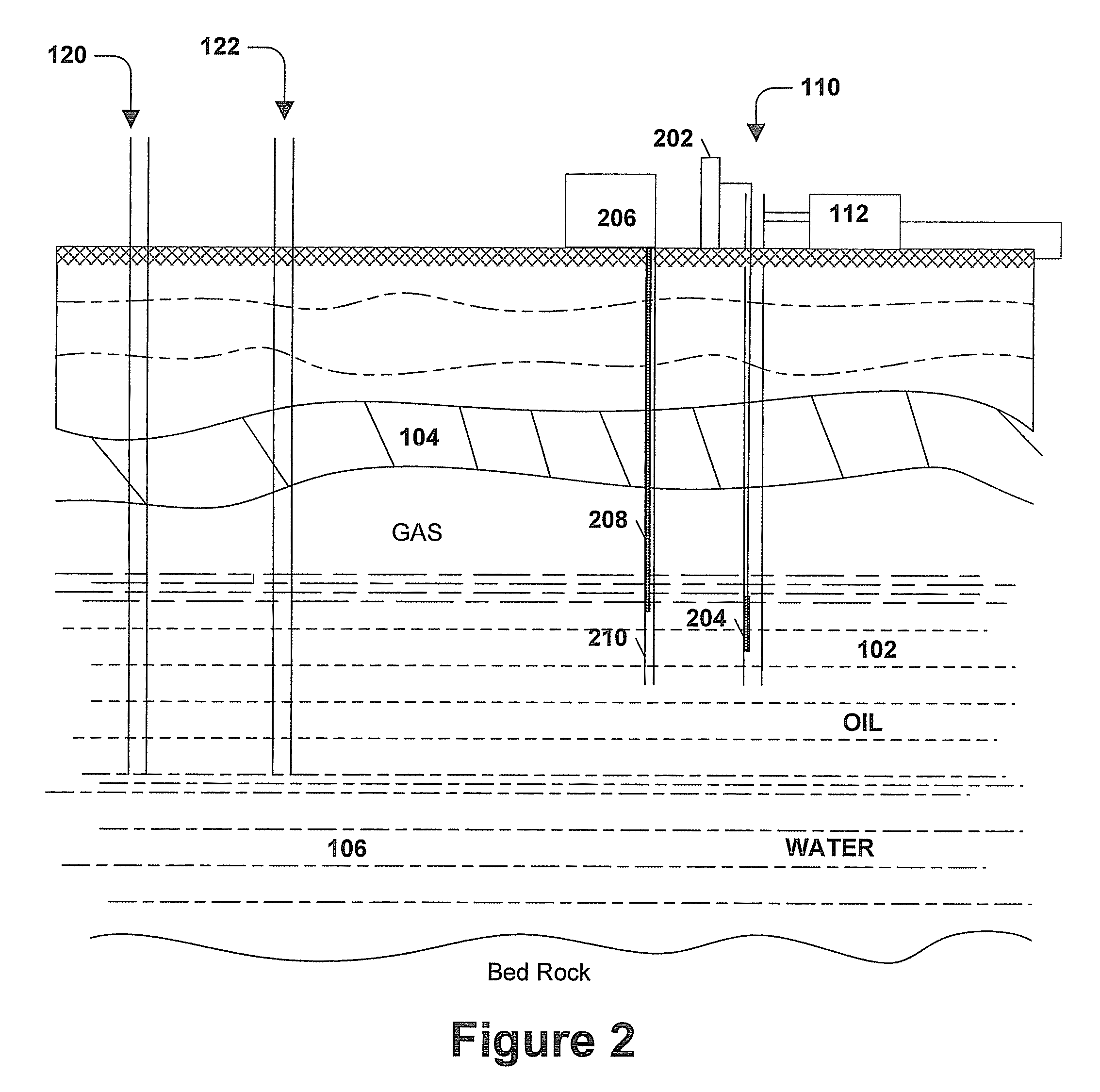

Methods for increasing oil production

InactiveUS20120055685A1Enhance productionReduce solubilityOther gas emission reduction technologiesFluid removalOil productionChemistry

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells is disclosed. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir. Petroleum recovery can be further enhanced through the use of recycling.

Owner:JAMES K & MARY SANDERS FAMILY +1

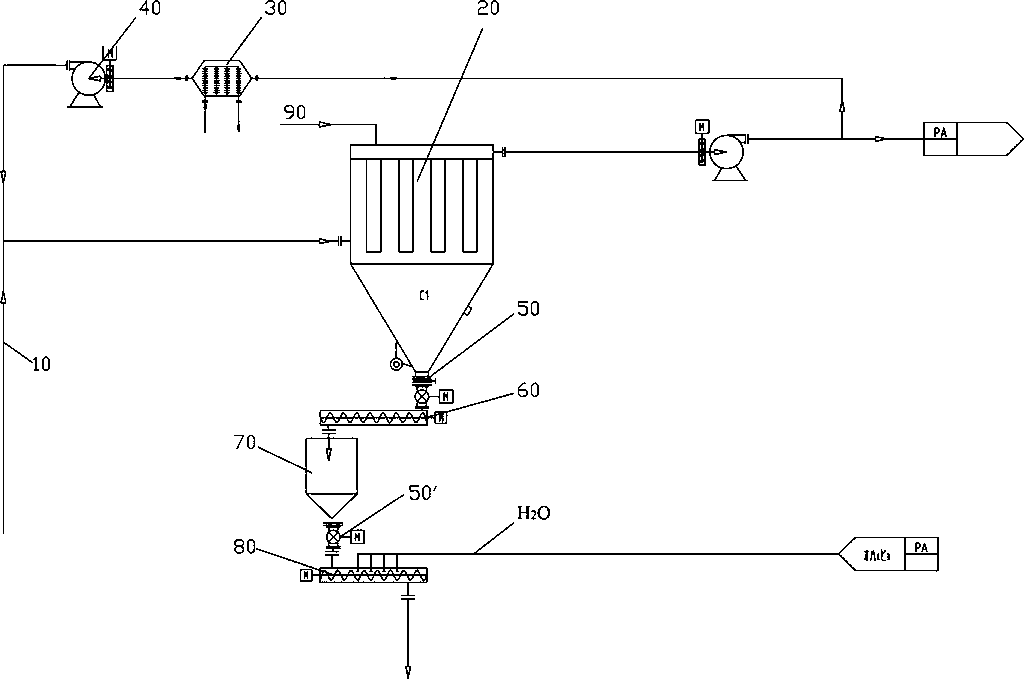

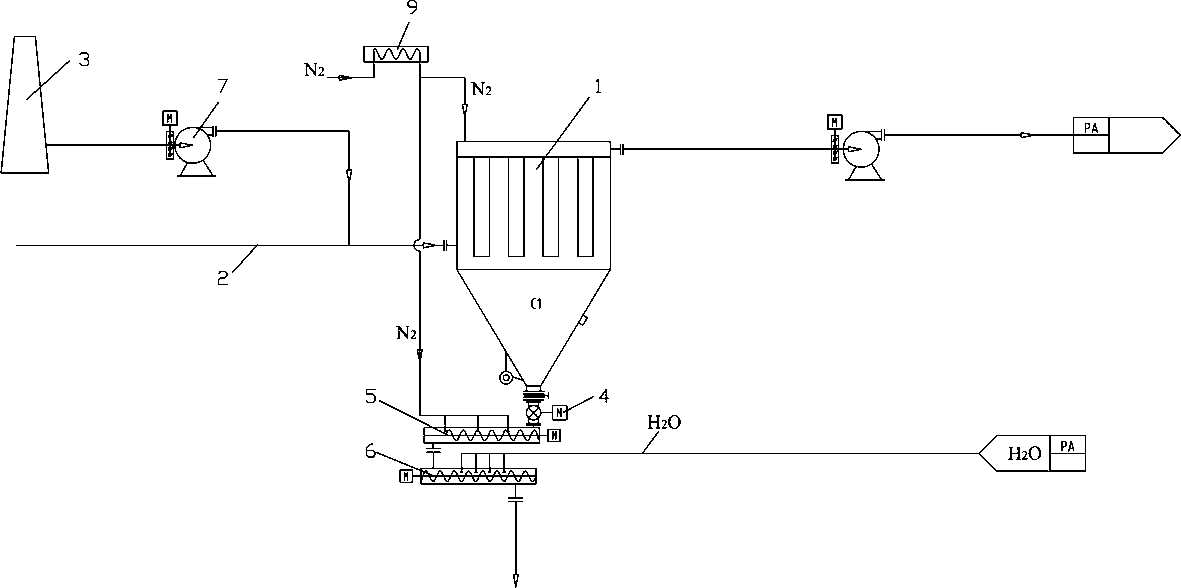

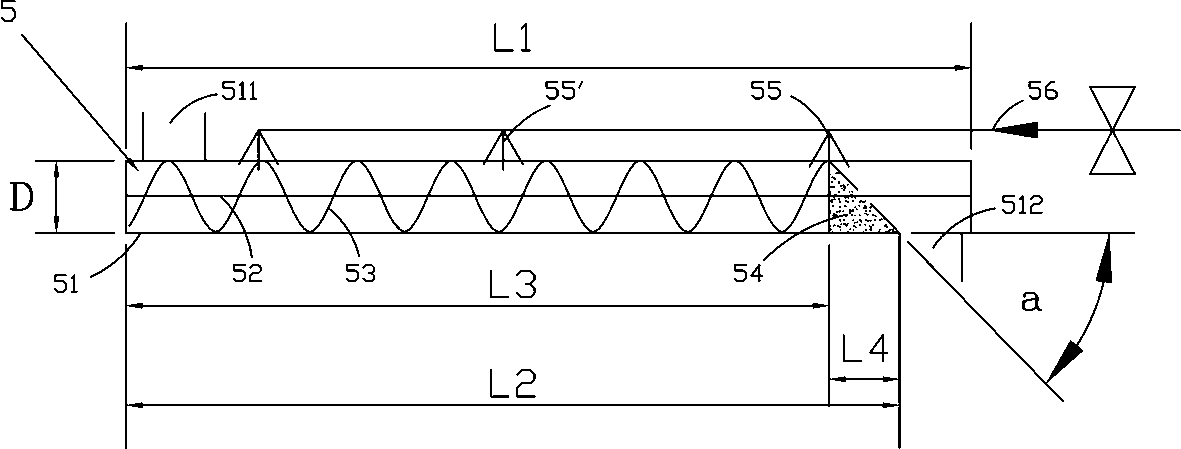

Dedusting method and system for coal moisture control

ActiveCN102847383AReduce middlewareClean evenlyDispersed particle filtrationCoke ovensMoistureEnvironmental engineering

The invention provides a dedusting method and a system for coal moisture control. The method includes mixing flue gas from drier outlet with high-temperature coke oven flue gas, introducing into a bag dust collector, introducing coal dust from the dust bin of the bag dust collector into an ash discharge screw via a rotary ash unloading valve, humidifying the dried coal dust in a humidifying stirrer, discharging, and recovering. The ash discharge screw has gas seal and packing seal structure. The invention solves the problems of existing coal moisture control process, such as high flammability, explosiveness, dewing of flue gas induced difficulty in ash removal, and blocking of ash discharge system caused by formation of a large amount of water vapor due to contact of hot coal dust with cold water.

Owner:BAOSHAN IRON & STEEL CO LTD

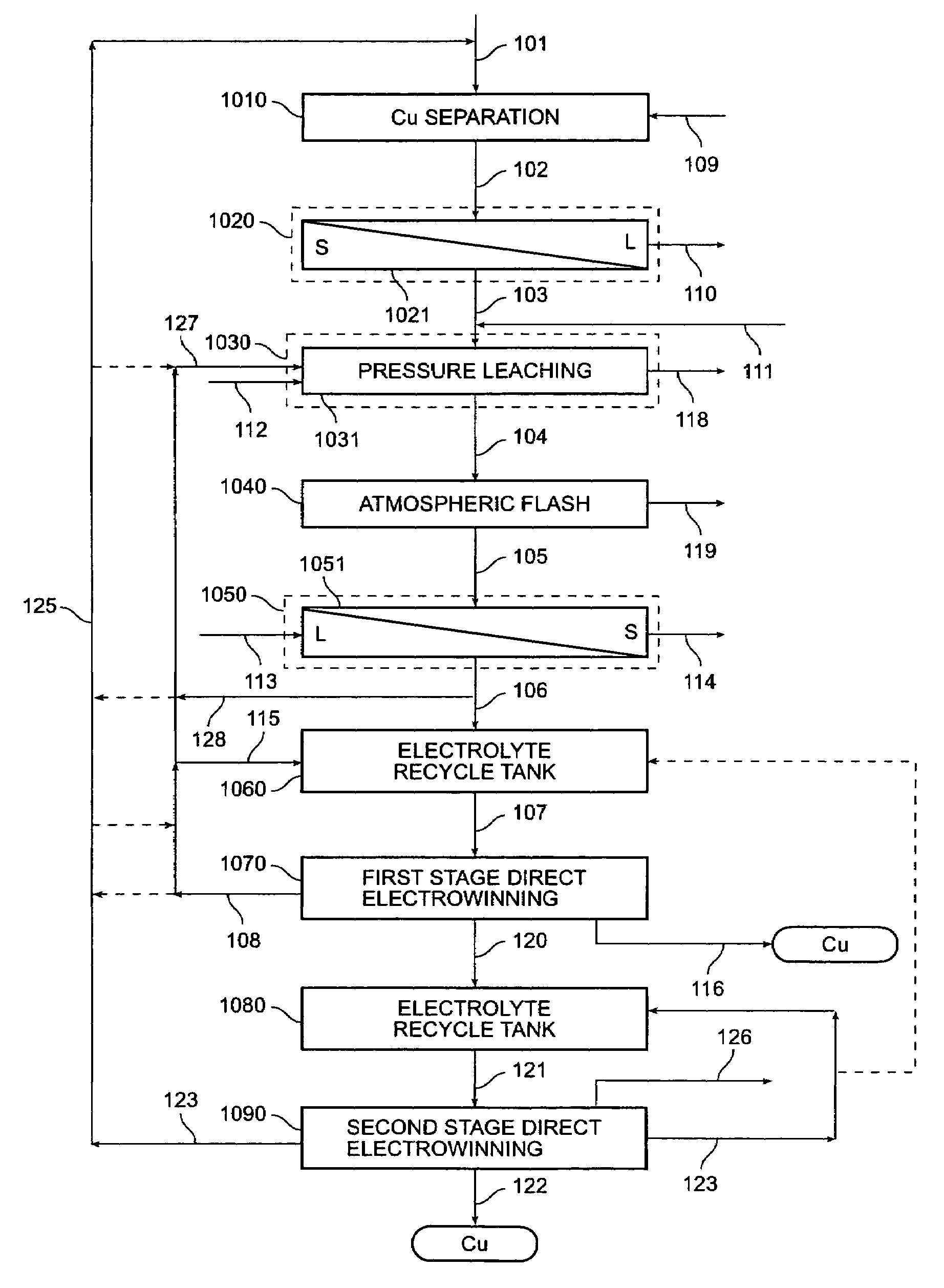

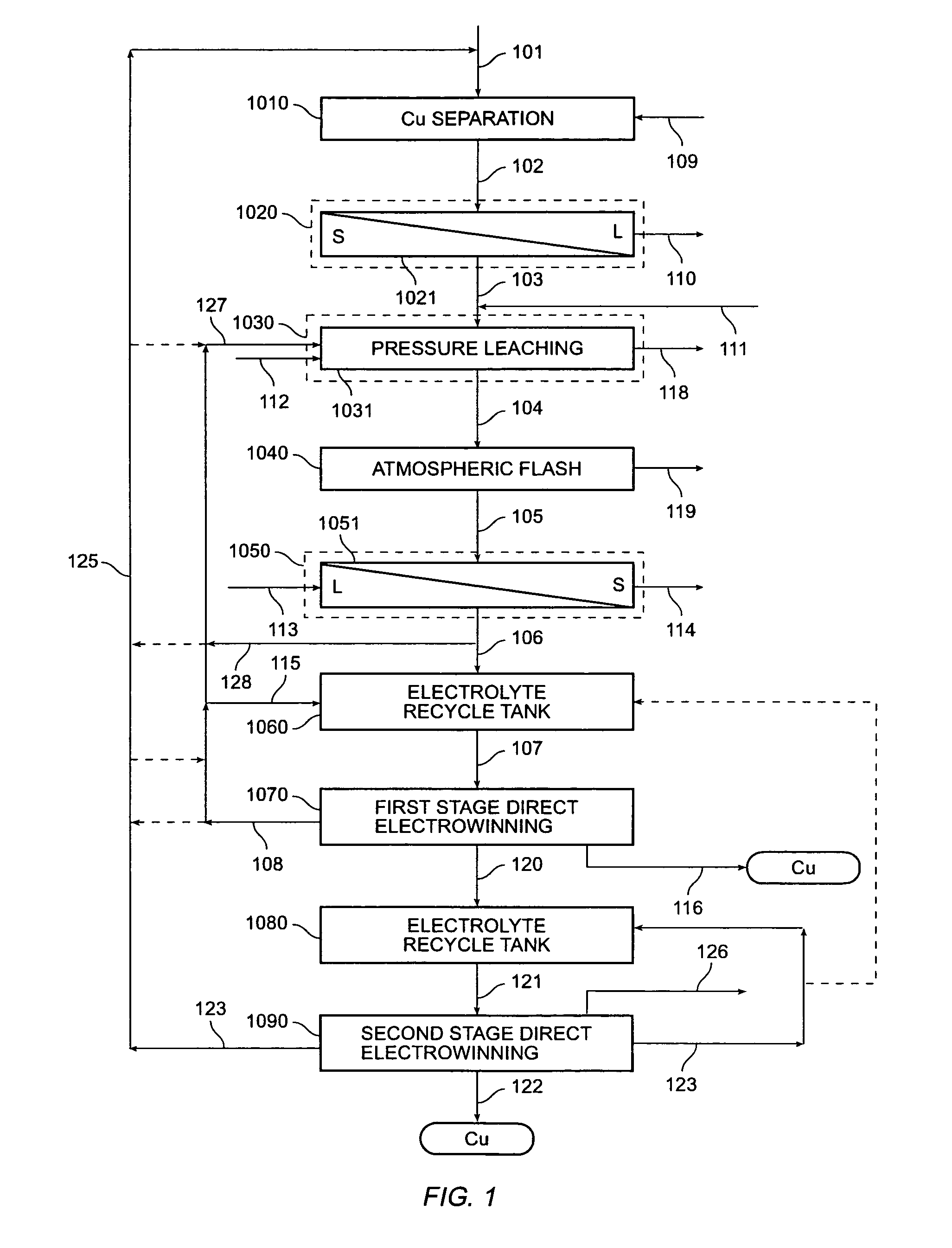

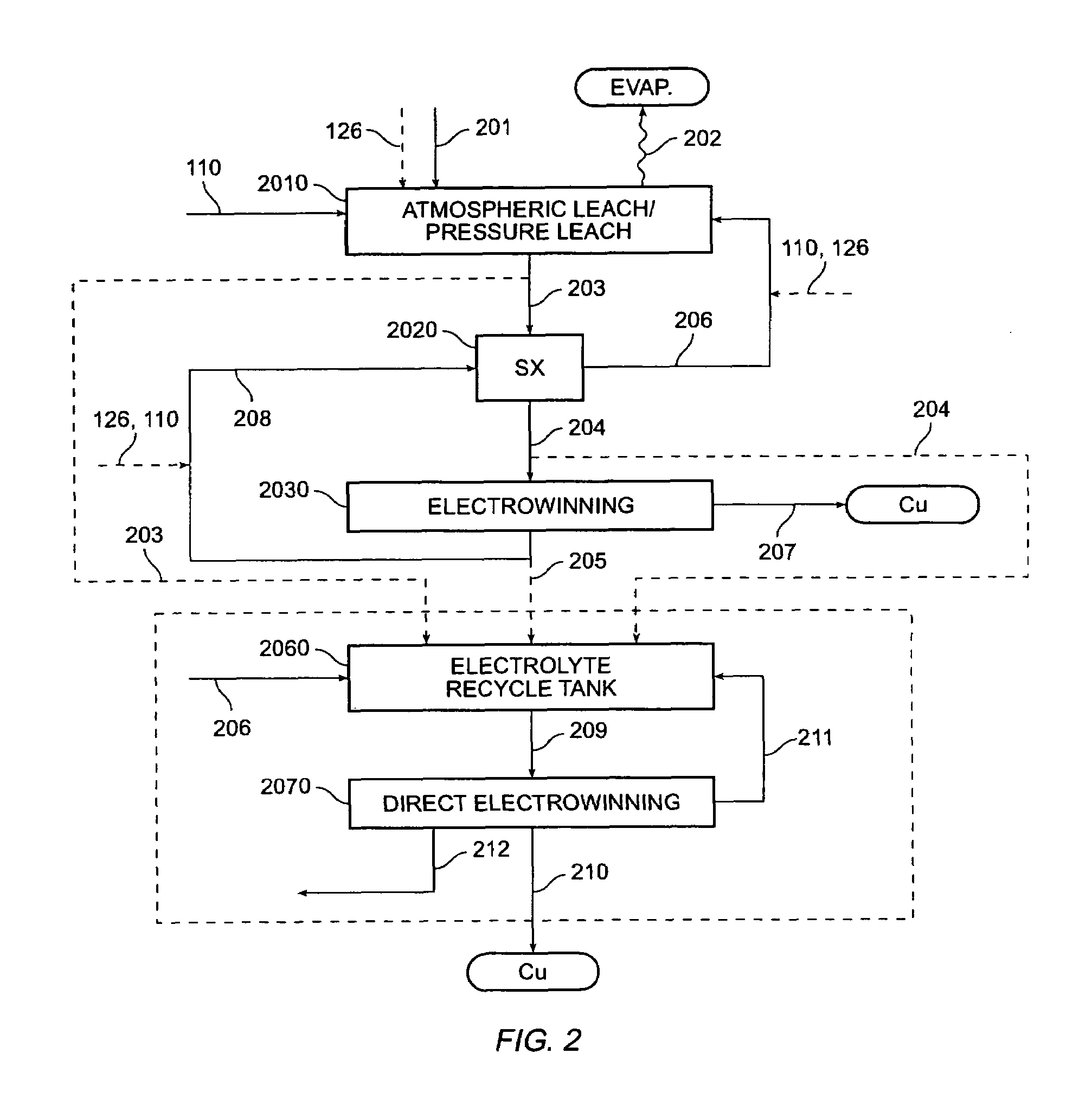

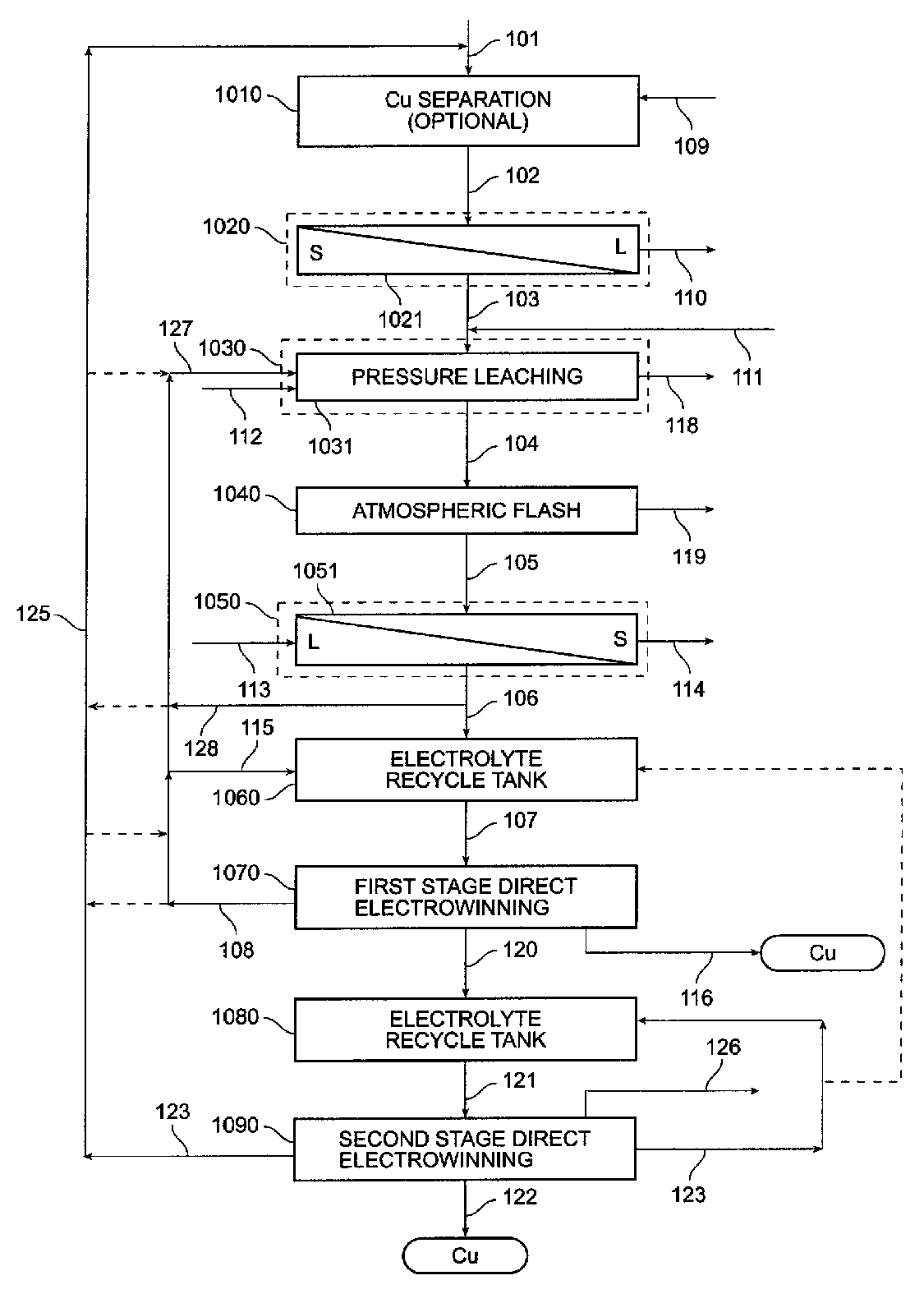

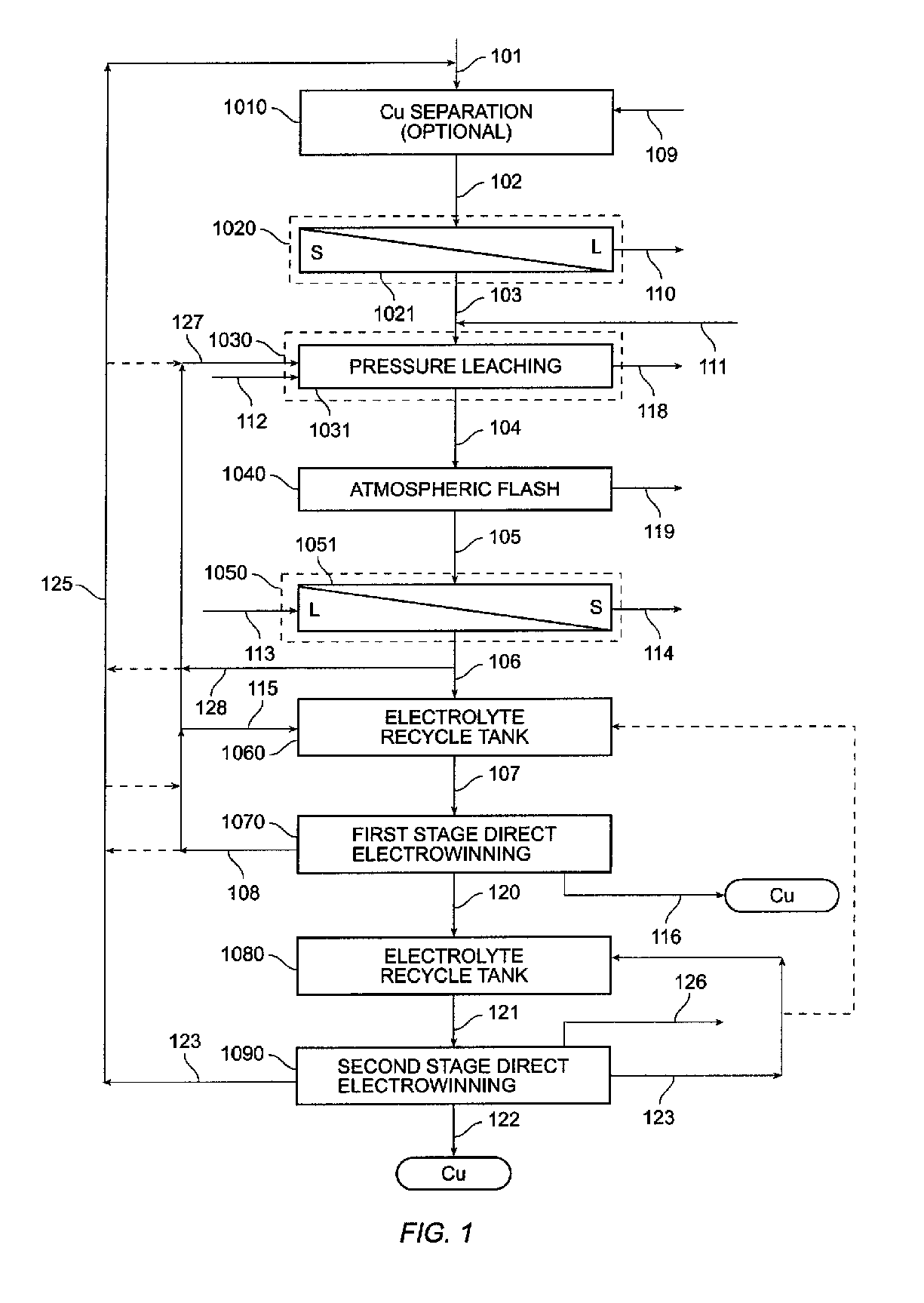

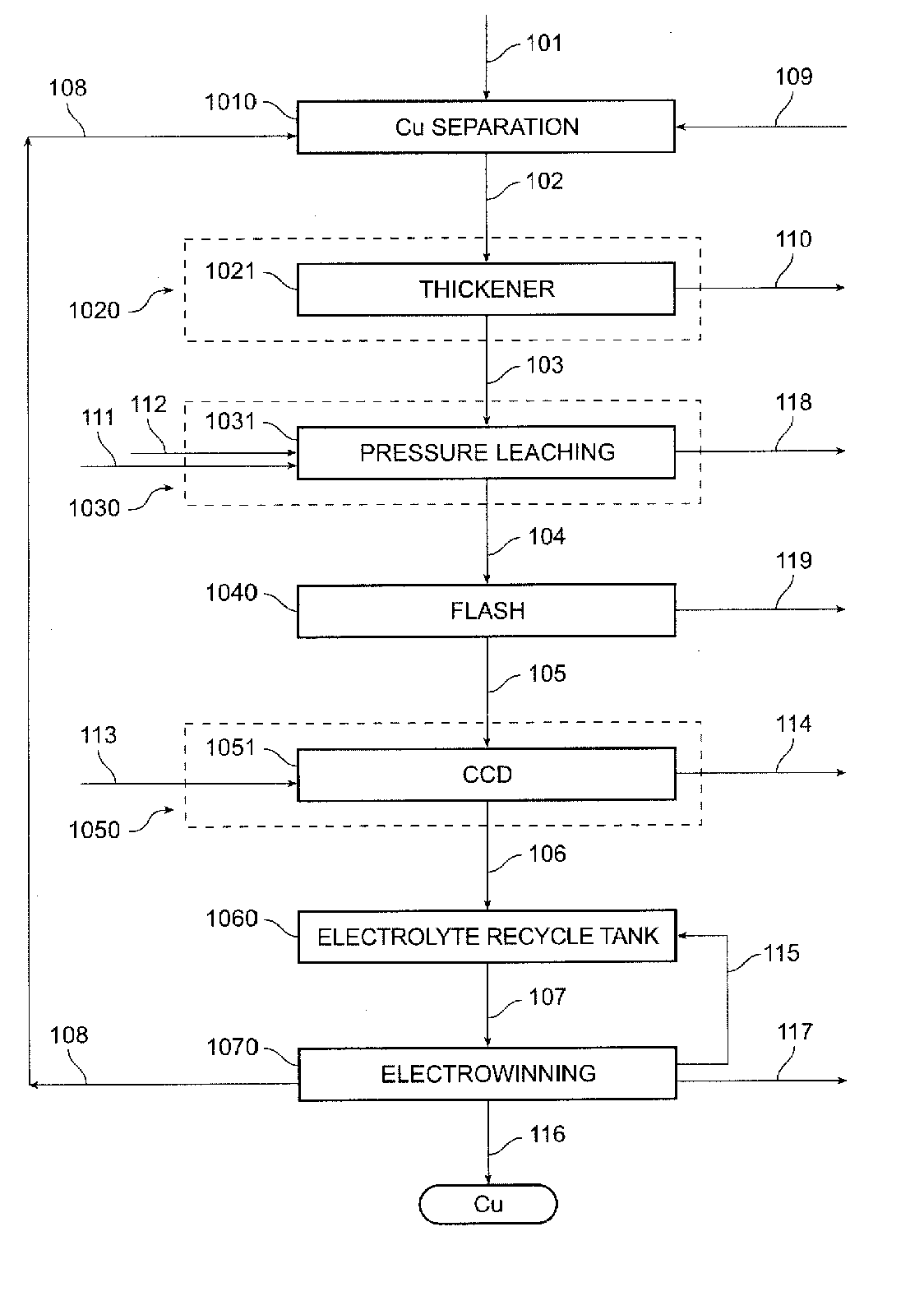

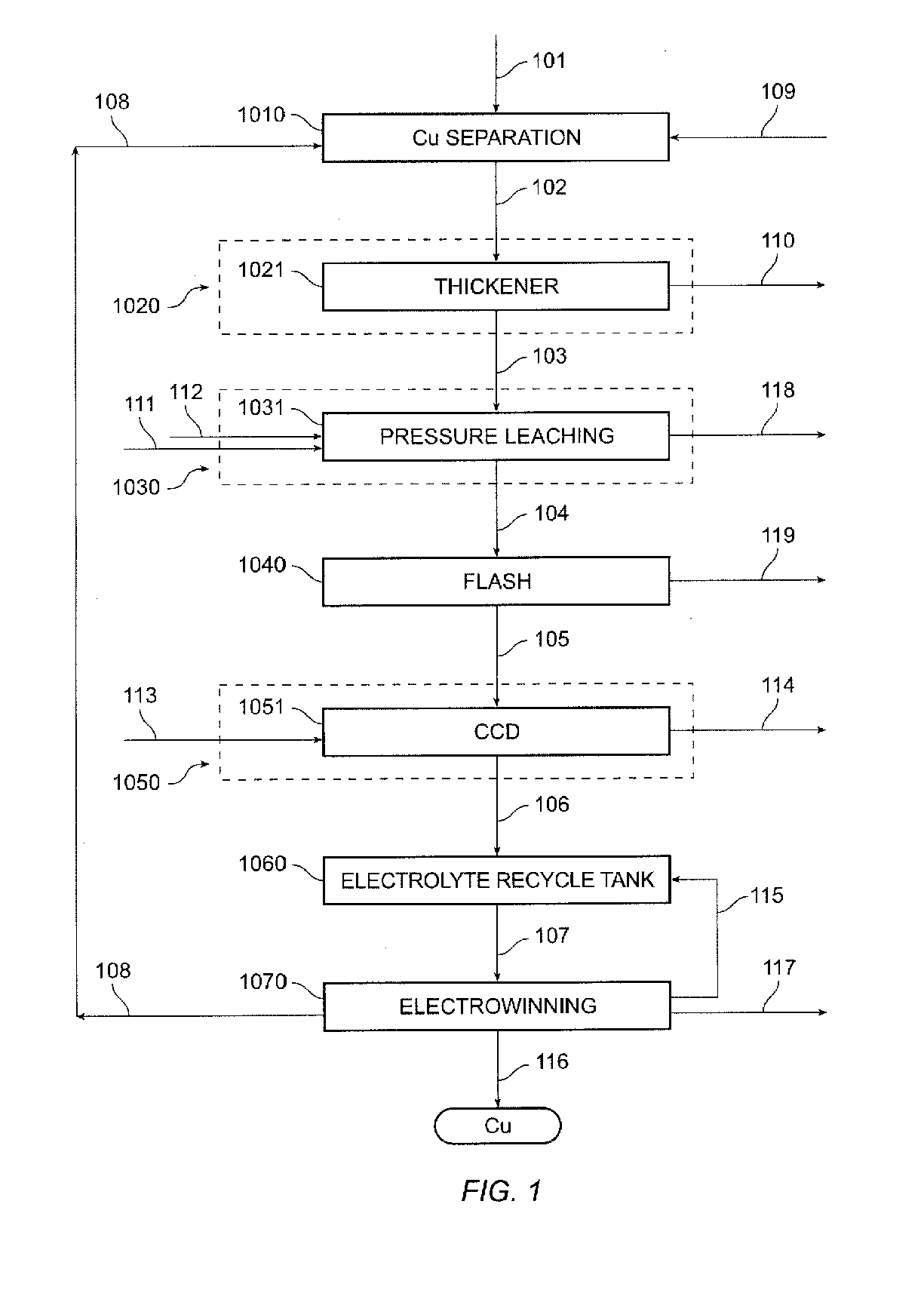

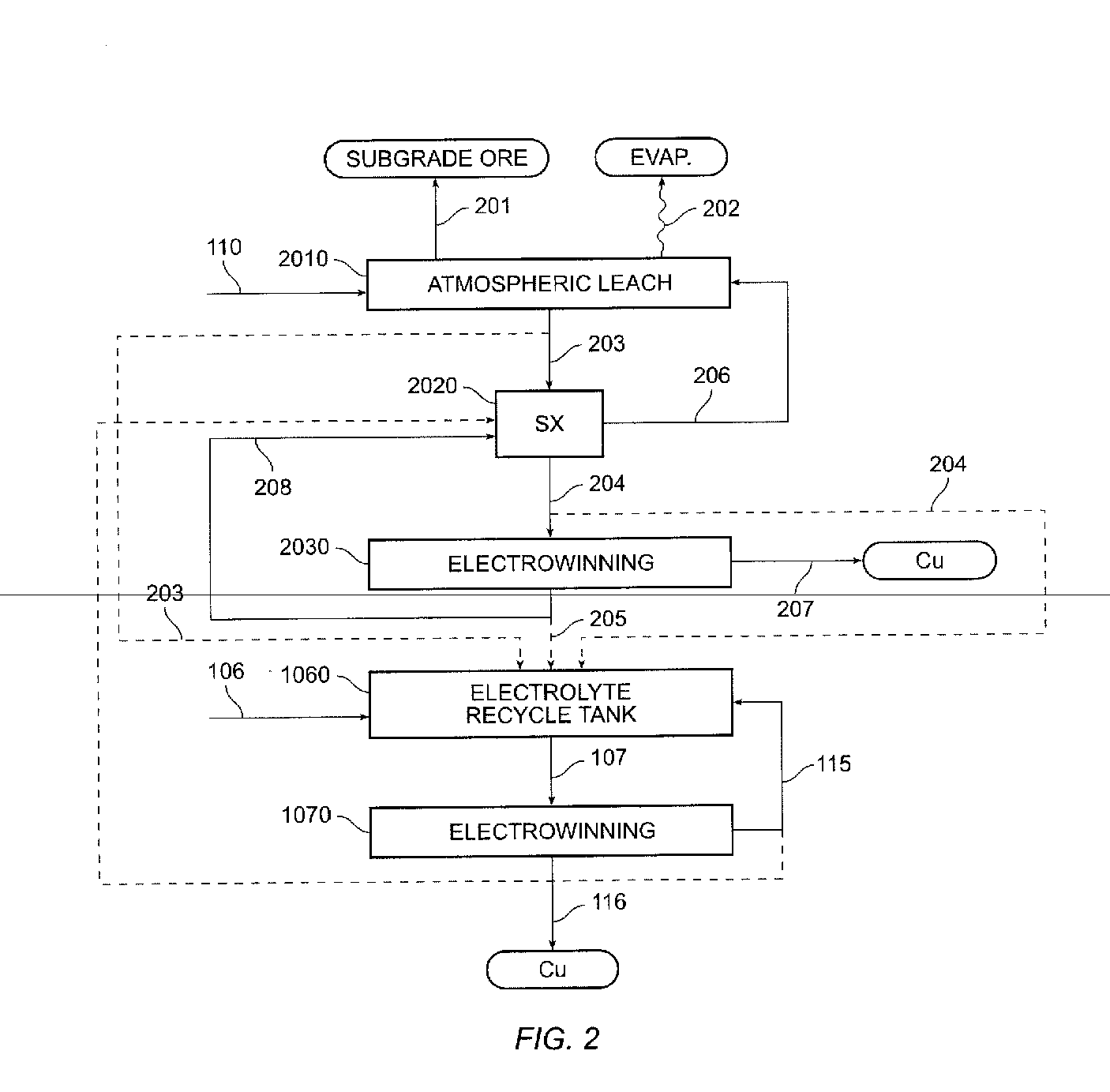

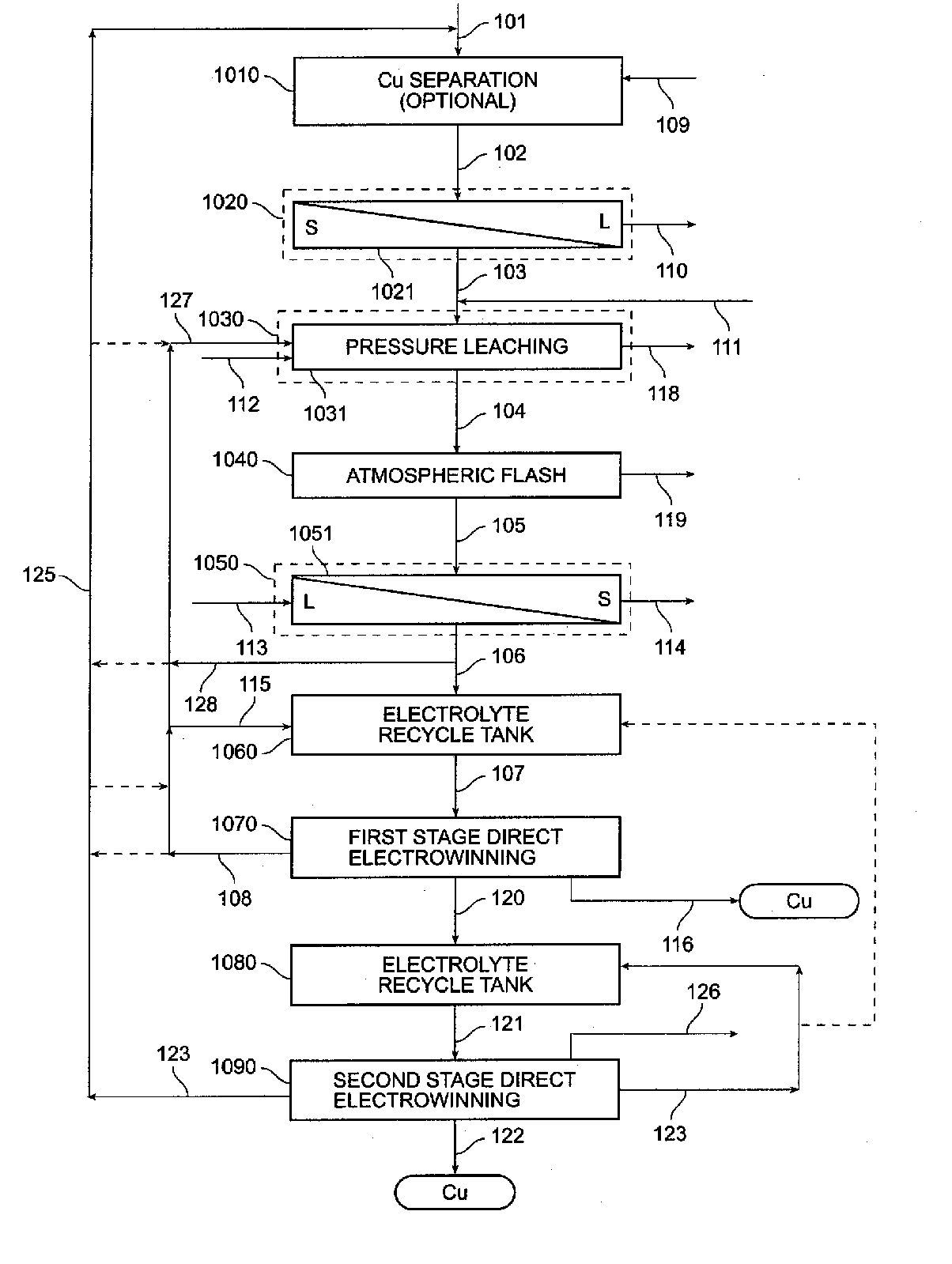

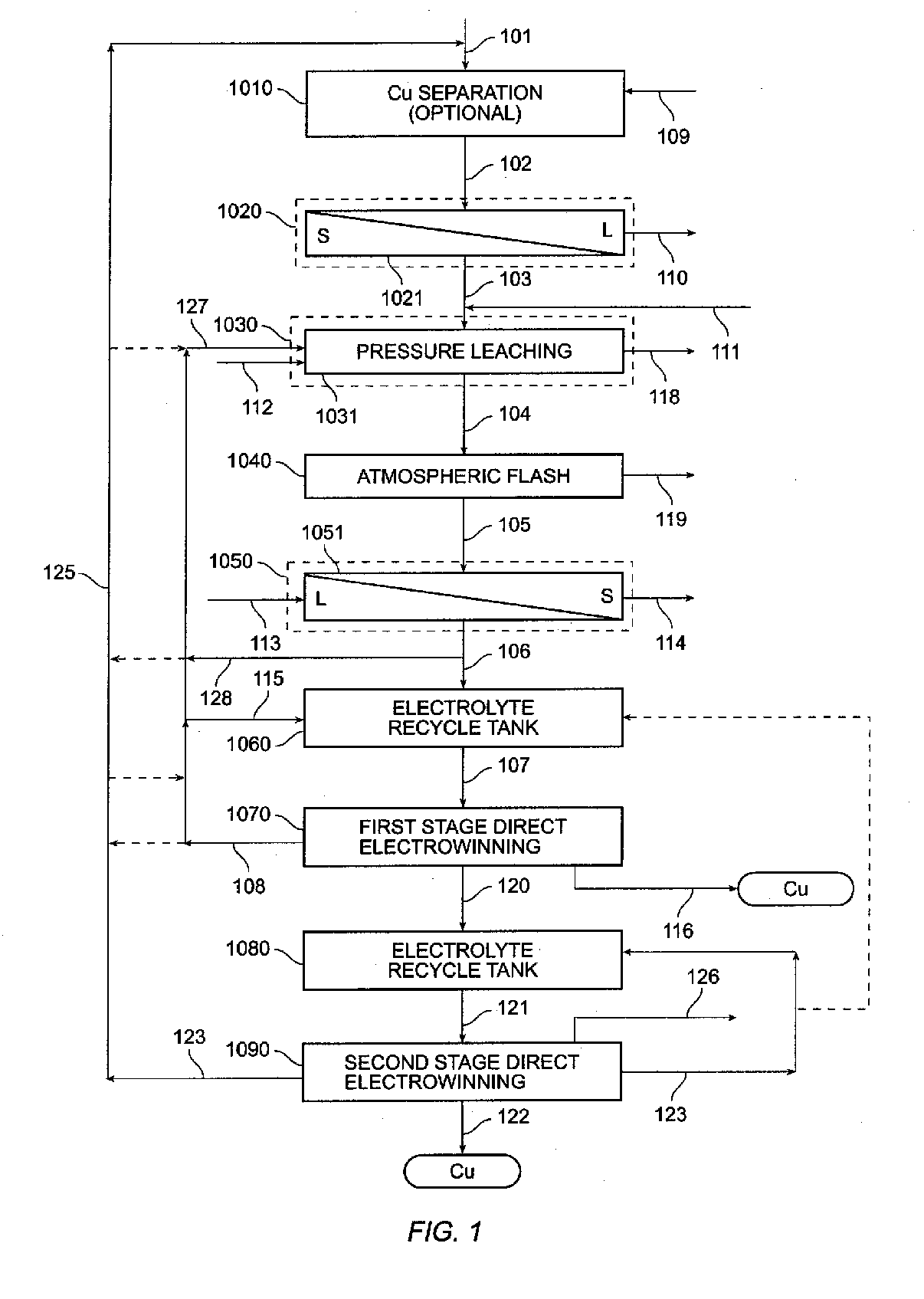

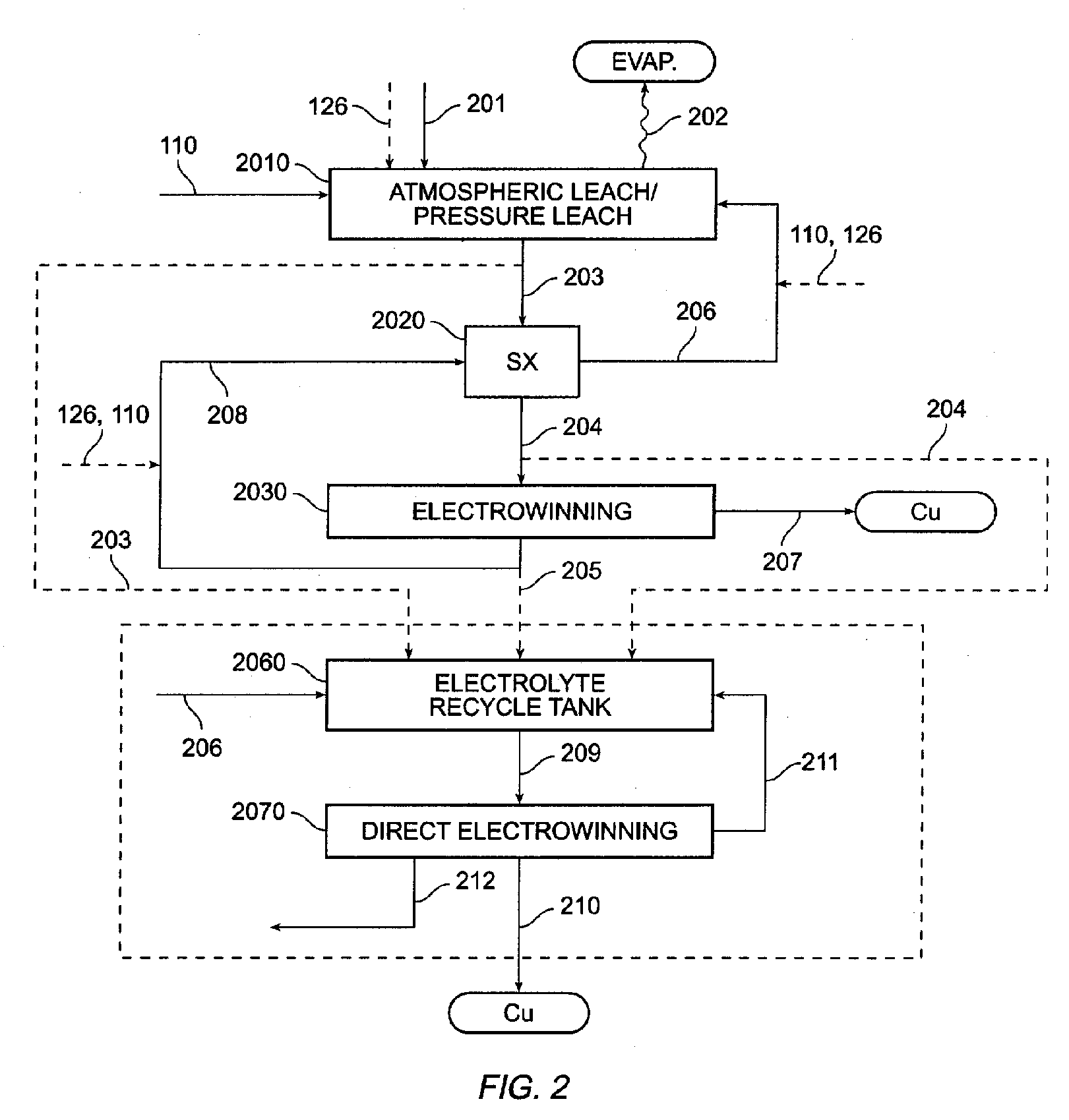

Process for multiple stage direct electrowinning of copper

InactiveUS7476308B2Low cost recyclingReduce expensesPhotography auxillary processesProcess efficiency improvementElectrolysisCopper

A system and process for recovering copper from a copper-containing ore, concentrate, or other copper-bearing material to produce high quality cathode copper from a leach solution without the use of copper solvent / solution extraction techniques or apparatus. A process for recovering copper from a copper-containing ore generally includes the steps of providing a feed stream containing comminuted copper-containing ore, concentrate, or other copper-bearing material, leaching the feed stream to yield a copper-containing solution, conditioning the copper-containing solution through one or more physical or chemical conditioning steps, and electrowinning copper directly from the copper-containing solution in multiple electrowinning stages, without subjecting the copper-containing solution to solvent / solution extraction prior to electrowinning.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Printing and forming process of environment-friendly APET plastic products

InactiveCN106827598AStable printingBeautiful printPattern printingFlat articlesScreen printingPlastic film

The invention relates to a processing process of APET plastic products, in particular to a printing and forming process of environment-friendly APET plastic products. The printing process comprises the following steps:1) making an APET plastic plate; 2) embossing a leading wire on the APET plastic plate and laminating a film on the APET plastic plate; 3) cutting the APET plastic plate; 4) carrying out silk-screen printing; 5) coating the APET plastic plate with a protective film layer; 6) pressing sides; 7) carrying out die-cutting forming; and 8) carrying out high-frequency splicing. According to the process, the APET plastic is used as an original material of the plastic products so that the environment can be protected, the resources can be recycled, and the processing cost can be reduced; the reasonable printing process is adopted so that the pattern printing and the pattern die-cutting forming of the APET plastic sheet material can be smoothly completed in shortest time and in most convenient operation steps; and the most suitable forming process is adopted, so that the APET sheet material can be stereoscopically formed smoothly, and the APET plastic products which are attractive in printing, stable in quality and energy-saving can be obtained.

Owner:东莞市巨泓彩色印刷有限公司

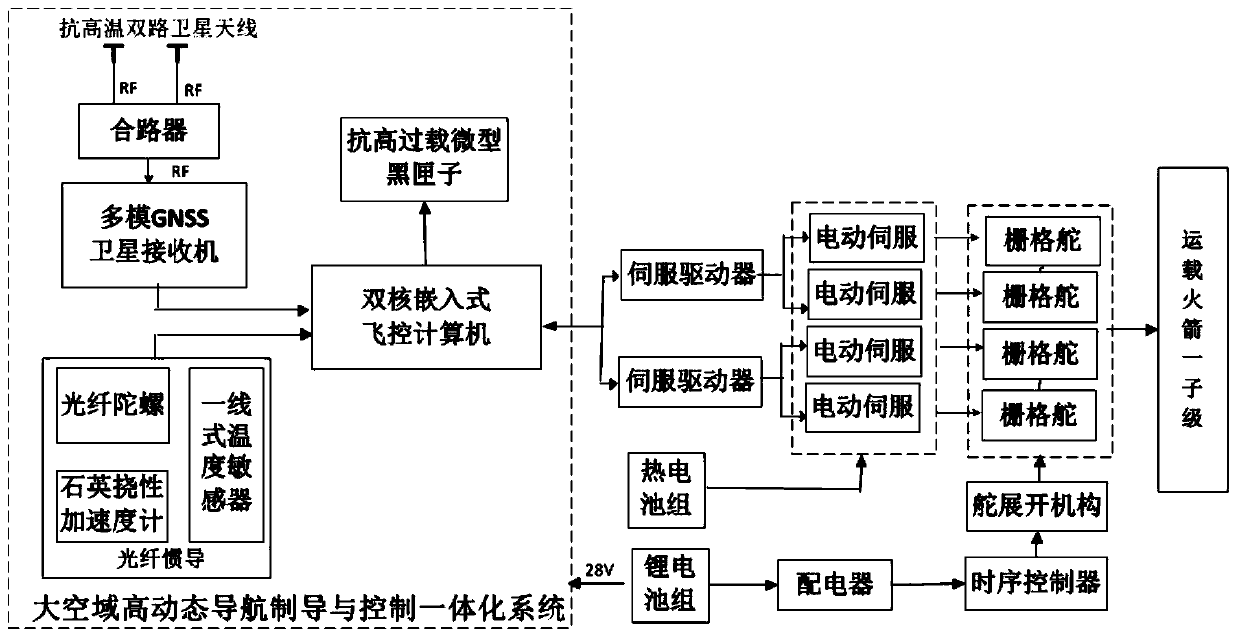

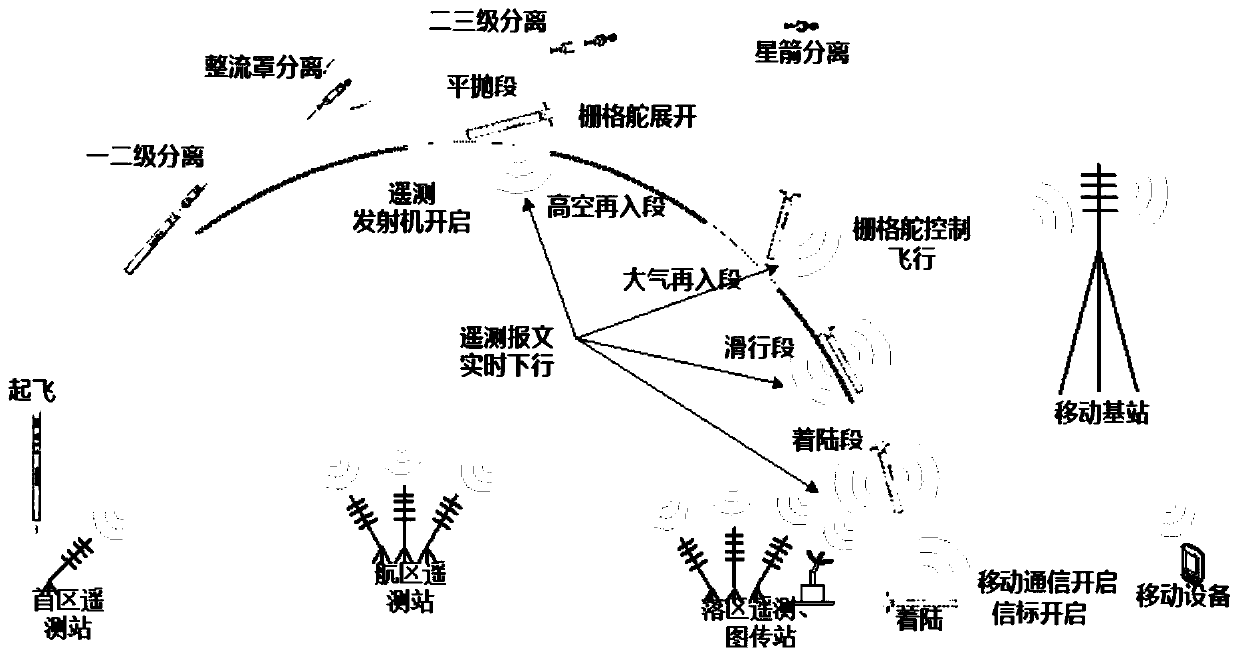

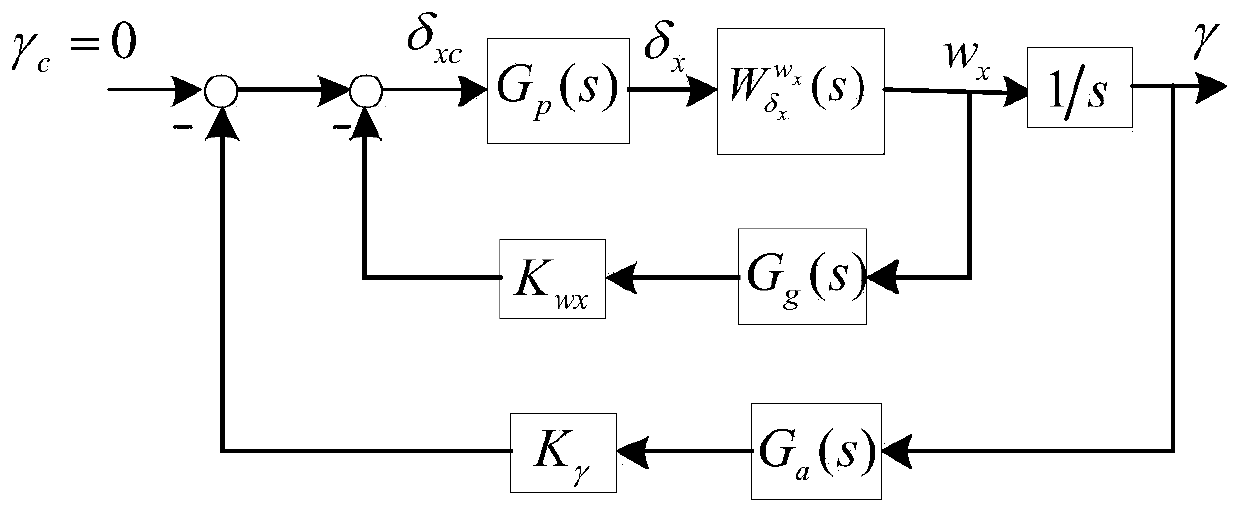

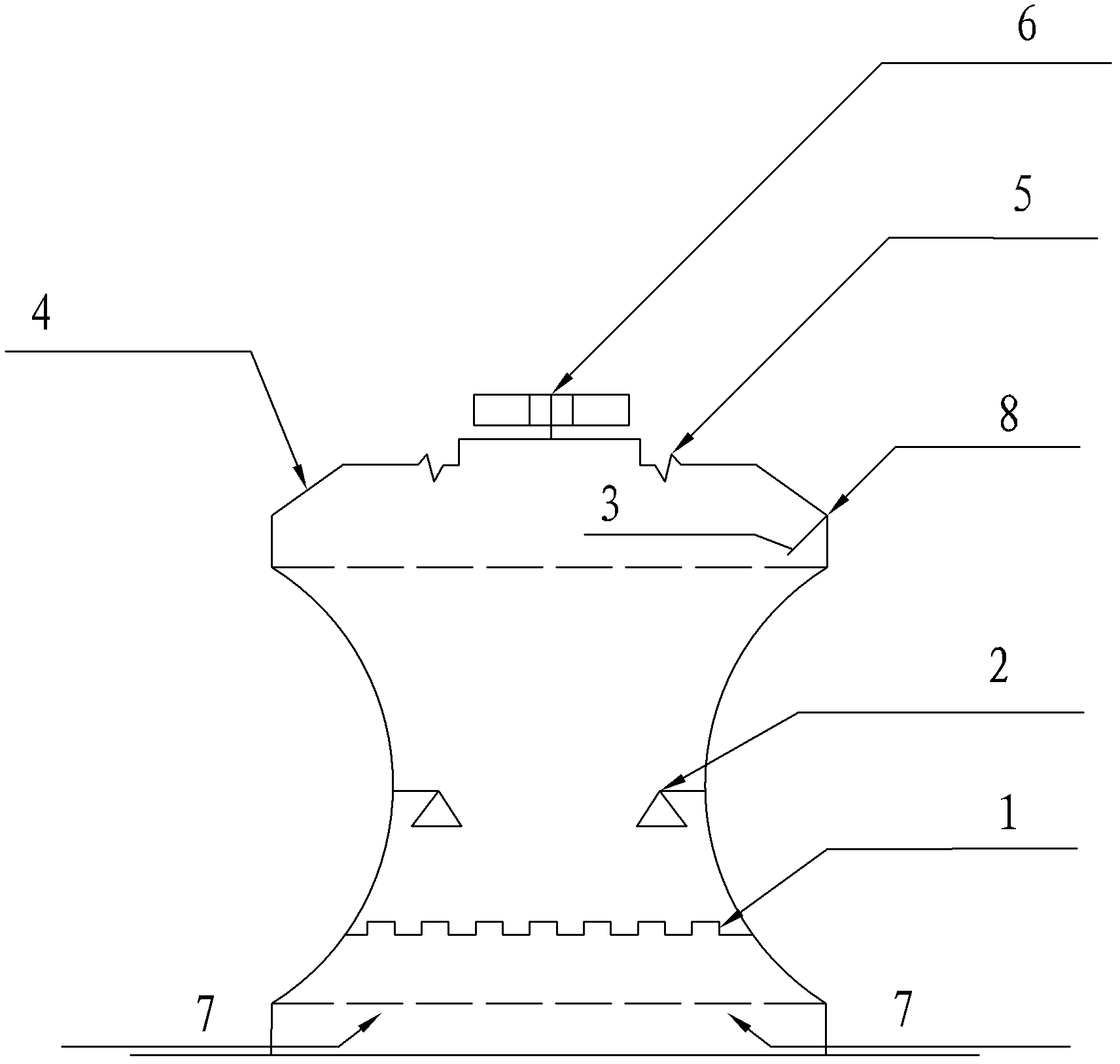

Precise vertical recovery control method for large-airspace high-dynamic rocket sublevel landing area

InactiveCN111595210ALow cost recyclingAchieve flight verificationSelf-propelled projectilesChannel couplingGuidance control

The invention discloses a precise vertical recovery control method for a large-airspace high-dynamic rocket sublevel landing area. A guidance control system adopts a quick time-varying and multi-channel coupling attitude control method for design, an algorithm and a program operate on a dual-core embedded computer in a navigation and guidance control integrated system, control law calculation in alarge-airspace high-dynamic high-Mach flight state is carried out by using current Mach number and pose information, calculated by the dual-core embedded computer, of a rocket sub-stage, pitching, yawing and rolling channel control instructions of a rocket sub-stage grid rudder are solved in real time, and the sub-stage is guided to vertically land towards a target point area. The method is mainly used for solving the accurate control problem of the sub-stage of a carrier rocket under the conditions of violent flight state change, high Mach, large airspace and high dynamic flight, the systemis simple in structure, convenient to implement and high in universality, and the main flight task of the carrier rocket is not affected.

Owner:NANJING UNIV OF SCI & TECH

Increasing oil production

InactiveUS20100126719A1Increase oil productionMaximize CO productionOther gas emission reduction technologiesFluid removalAlkaline earth metalProduct gas

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells is disclosed. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. Additional explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir.

Owner:JAMES K & MARY SANDERS FAMILY +1

Process for multiple stage direct electrowinning of copper

InactiveUS7462272B2Low cost recyclingReduce expensesPhotography auxillary processesElectrolysis componentsElectrolysisSolvent

A system and process for recovering copper from a copper-containing ore, concentrate, or other copper-bearing material to produce high quality cathode copper from a leach solution without the use of copper solvent / solution extraction techniques or apparatus. A process for recovering copper from a copper-containing ore generally includes the steps of providing a feed stream containing comminuted copper-containing ore, concentrate, or other copper-bearing material, leaching the feed stream to yield a copper-containing solution, conditioning the copper-containing solution through one or more physical or chemical conditioning steps, and electrowinning copper directly from the copper-containing solution in multiple electrowinning stages, without subjecting the copper-containing solution to solvent / solution extraction prior to electrowinning.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Silk degumming/scouring agent and applications thereof

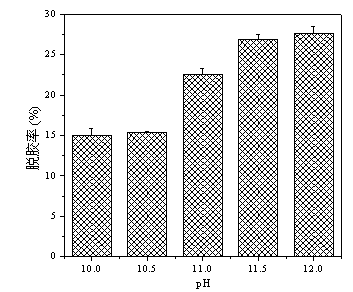

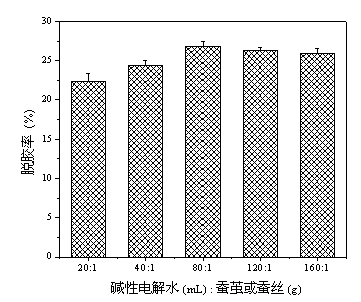

The invention discloses a silk degumming / scouring agent and applications thereof, and concretely discloses a silk degumming / scouring agent strongly-alkaline electrolytic water, and new uses and new technologies of the silk degumming / scouring agent in processing processes comprising silk wadding quilt processing, cut bave or silk degumming, silk cotton, pure silk blank material refining and the like. Common tap water directly is directly electrolyzed through a water electrolyzing device or an electrolytic tank to form strongly-alkaline electrolytic water having a pH value of 11.0-12.0, and the strongly-alkaline electrolytic water can be used as a silk wadding sheet scouring agent, a cocoon shell or silk degumming agent, a silk cotton scouring agent, a pure silk or blank silk scouring agent, and the like. The silk degumming / scouring agent has the advantages of small damage to silk fibers, complete degumming, maintenance of the original resilience and other mechanical performances of the fibers, realization of direct low-cost high-efficiency recovery of sericin from a degum solution without desalination, and avoiding of the server environmental pollution of sericin-containing alkaline wastewater and the huge biological resource waste.

Owner:SUZHOU UNIV

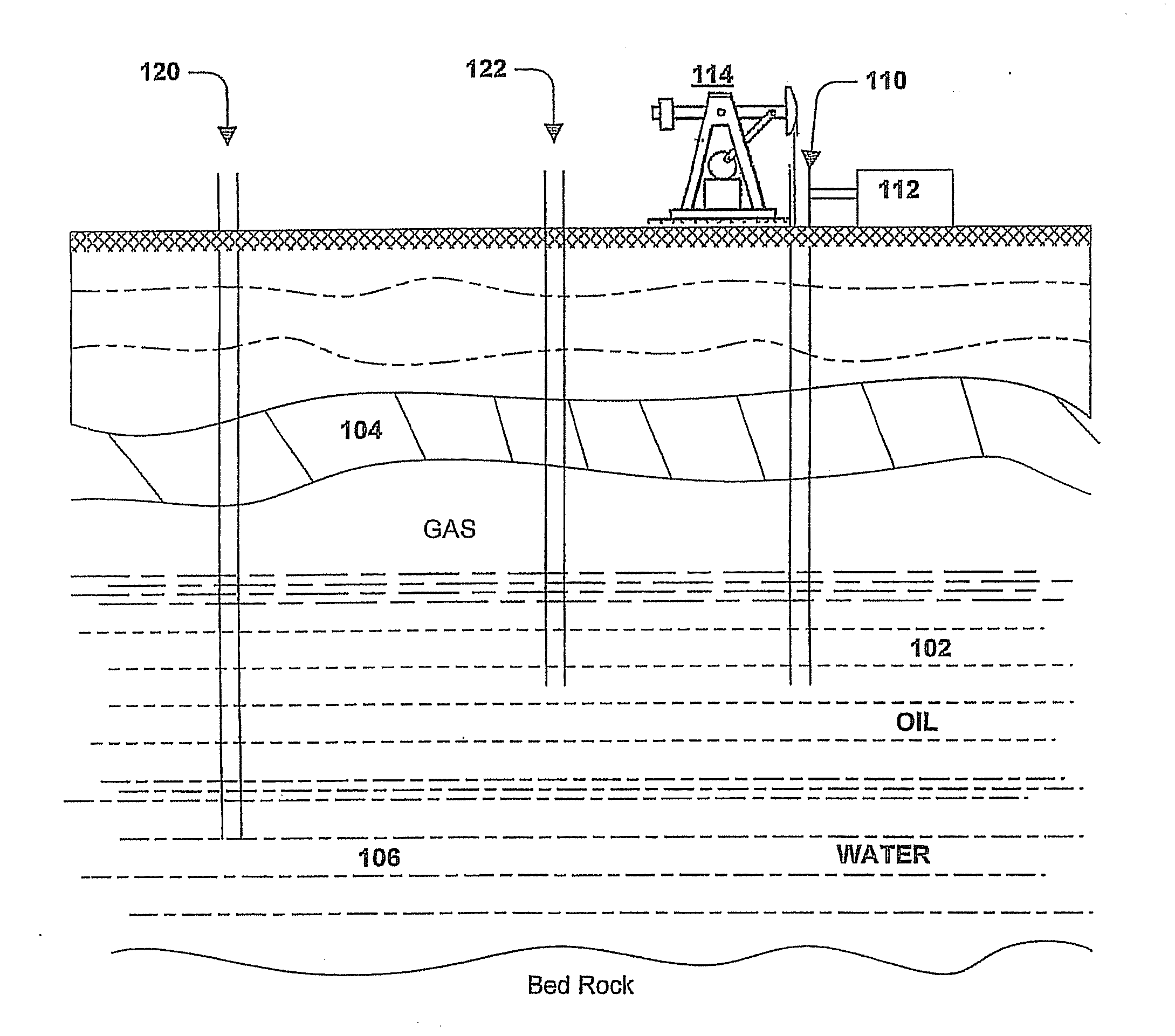

Methods for increasing oil production

InactiveUS20100126737A1Increase oil productionMaximize CO productionOther gas emission reduction technologiesFluid removalAlkaline earth metalOil production

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells is disclosed. An alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir. Petroleum recovery can be further enhanced through the use of one or more techniques to reduce petroleum viscosity including sonication and microwave radiation.

Owner:YANG DUCK JOO +1

Method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water

InactiveCN102605436ALow costIncrease productionMechanical impurity removalSilk reelingWater bathsWastewater

The invention discloses a method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water, falling into silk making technical field. The method includes subjecting common tap water to electrolytic treatment via water electrolyzer or electrolytic cell, to obtain strongly alkaline electrolyzed water with pH of 11.0-12.0; performing constant-temperature oscillation swelling soaking treatment on silkworm cocoon in strongly alkaline electrolyzed water at 60-80 DEG C directly for 5-10 min; and taking strongly alkaline electrolyzed water as reeling hot water bath, transferring the swollen silkworm cocoon to the reeling hot water bath at 40-70 DEG C, and immediately reeling silk, to obtain raw silk product. The inventive method performs reeling at low temperature, to improve product quality and save energy. The invention can realize industrial production of strongly alkaline electrolyzed water at low cost and high yield, high-efficiency low-cost recovery of sericin, and cyclic utilization of reeling waste water after simple purification treatment, to thereby avoid environmental pollution caused by a large amount of waste liquid.

Owner:SUZHOU UNIV

Method for recovering copper from copper-containing materials using direct electrowinning

InactiveUS20060196313A1Easy to controlQuality improvementElectrolysis componentsPhotography auxillary processesElectrolysisCopper

A method for recovering copper from a copper-containing ore, concentrate, or other copper-bearing material to produce high quality cathode copper from a leach solution without the use of copper solvent extraction techniques or apparatus. A method for recovering copper from a copper-containing ore generally includes the steps of providing a feed stream containing comminuted copper-containing ore, concentrate, or other copper-bearing material, leaching the feed stream to yield a copper-containing solution, conditioning the copper-containing solution through one or more physical or chemical conditioning steps, and electrowinning copper directly from the copper-containing solution, without subjecting the copper-containing solution to solvent extraction.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Method for absorbing and recovering high-concentration oil vapor

InactiveCN101822930AImprove adsorption capacityImprove adsorption efficiencyDispersed particle separationHigh concentrationHigh absorption

The invention discloses a method for absorbing and recovering high-concentration oil vapor, which belongs to the technical field of oil vapor recovery, and comprises the following steps that: the high-concentration oil vapor flows through an absorption column filled with a mesopore absorbent and micropore absorbent double-layer fixed bed under normal temperature and normal pressure, the mesopore absorbent is arranged at the lower part of the absorption column, and the micropore absorbent is arranged at the upper part of the absorption column; and the absorbent absorbing organic substances is vacuumized and desorbed, and the desorbed oil vapor is condensed or absorbed and then returns to an oil tank. The concentration of the oil vapor at an outlet of the absorption column processed by the invention can be reduced to 25g / cm3, which can achieve the national control standard of oil vapor pollutant emission; and the oil product returning to the oil tank continues to be used, and the oil vapor recovery rate reaches more than 93 percent. According to the characteristics of the high-concentration oil vapor, the invention develops a double-layer fixed bed absorption process combined by the mesopore high molecular polymer absorbent and the micropore absorbent, and the high absorption capacity of the mesopore absorbent and the high absorption efficiency of the micropore absorbent are coupled, thereby achieving the efficient utilization of the high-concentration oil vapor.

Owner:NANJING UNIV

Increasing oil production

InactiveUS8347973B2Low cost recyclingIncrease oil productionOther gas emission reduction technologiesFluid removalAlkaline earth metalExplosive Agents

A method of recovering petroleum from dormant oil wells or increasing the production of oil wells. An alkali metal or alkaline earth metal carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali metal or alkaline earth metal carbonate with an acid and / or by detonating the explosive composition.

Owner:JAMES K & MARY SANDERS FAMILY +1

Method for preheating shifted hydrogen by utilizing direct reduction iron furnace top gas

The invention relates to a method for preheating shifted hydrogen by utilizing direct reduction iron furnace top gas. The method comprises the following steps: cooling the furnace top gas to less than 180 DEG C, pressurizing to more than 9kg, obtaining normal-temperature shifted hydrogen with the H2 content more than or equal to 96% by using a CO-H2 technology, exchanging heat with the furnace top gas, heating to 330-480 DEG C, heating to 400-600 DEG C by using a partial oxidation method, adding into molten iron bath high-temperature raw gas, obtaining furnace feeding circulating reduction gas with the hydrogen-carbon ratio greater than 1.1, the temperature being 630-1050 DEG C and the oxidation degree (H2O + CO2) less than or equal to 3%, and introducing the circulating reduction gas into a direct reduction iron shaft furnace to produce direct reduction iron. According to the method, heat exchange is carried out between the furnace top gas and the shifted hydrogen, the temperature of the shifted hydrogen is further increased by the partial oxidation method, the heat of the direct reduction iron furnace top gas, the heat generated by shift reaction and water vapor in the furnace top gas are fully utilized, and the energy utilization efficiency is improved.

Owner:苏亚杰 +1

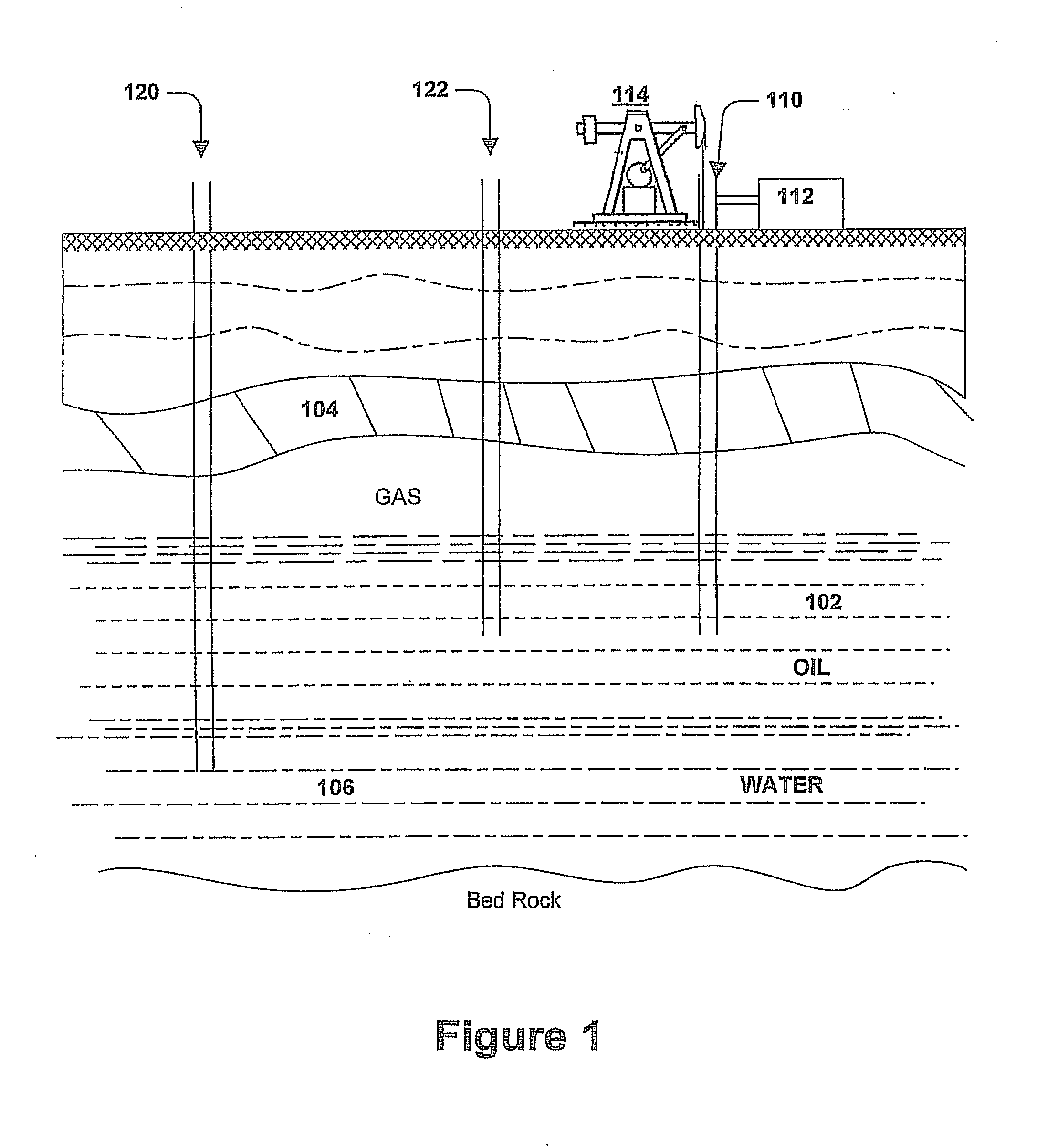

Methods for increasing oil production

InactiveUS8272449B2Low cost recyclingIncrease oil productionOther gas emission reduction technologiesFluid removalAlkaline earth metalOil production

According to a method of recovering petroleum from dormant oil wells or increasing the production of oil wells, an alkali or alkali earth carbonate is introduced into a water layer associated with a subterranean petroleum reservoir and / or an explosive composition is introduced into an oil layer associated with a subterranean petroleum reservoir. CO2 gas is produced by reacting the alkali or alkali earth carbonate with an acid and / or by detonating the explosive composition. An explosive composition can be introduced and detonated to achieve sufficient CO2 gas production to increase pressure within the subterranean petroleum reservoir. Petroleum recovery can be further enhanced through the use of recycling.

Owner:JAMES K & MARY SANDERS FAMILY +1

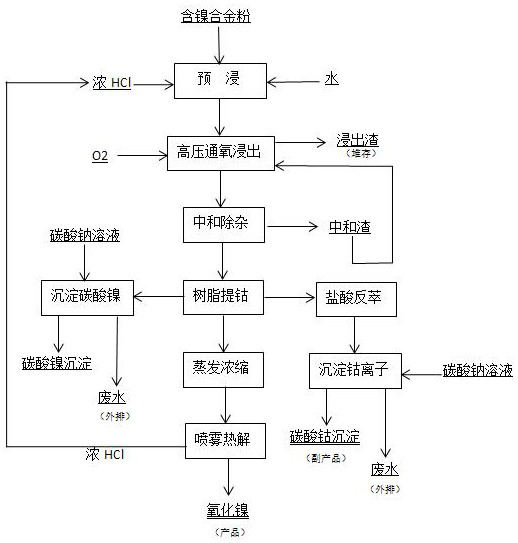

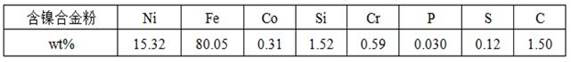

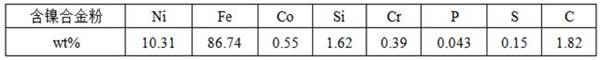

Treatment process of nickel-containing alloy powder in hydrochloric acid system

PendingCN113355520AAchieve recyclingLow cost recyclingProcess efficiency improvementSlagCobalt carbonyl

The invention provides a treatment process of nickel-containing alloy powder in a hydrochloric acid system. The treatment process comprises the following steps that (1) presoaking of the nickel-containing alloy powder is carried out, specifically, the nickel-containing alloy powder, concentrated hydrochloric acid and water are mixed, and then heated, stirred and presoaked; (2) high-pressure oxygen introduction and leaching is carried out, specifically, prepreg is poured into a high-pressure kettle, heating is carried out, oxygen is introduced to react for a certain time, cooling and liquid-solid separation are carried out, leaching residues are produced and stacked, and leaching liquid enters a next process; (3) neutralization and impurity removal are carried out, specifically, the pH value of the leaching liquid is adjusted by using nickel carbonate, a neutralization solution and neutralization slag are produced, and the neutralization slag returns to the leaching process; (4) cobalt extraction with resin is carried out, specifically, cobalt ions in the neutralization solution is adsorbed with the resin to produce cobalt carbonate precipitate and cobalt-extracted liquid; and (5) product preparation is carried out, specifically, nickel carbonate is prepared from a small part of cobalt-extracted liquid for a neutralization and impurity removal process, the rest liquid is concentrated and pyrolyzed, hydrochloric acid is produced for recycling, and nickel oxide is taken as a final product. According to the treatment process, the nickel oxide product is produced through the leaching, purifying and pyrolyzing processes, meanwhile, hydrochloric acid and a neutralizing and impurity-removing reagent are recycled, and the treatment process is clean and environmentally friendly.

Owner:金川镍钴研究设计院有限责任公司 +1

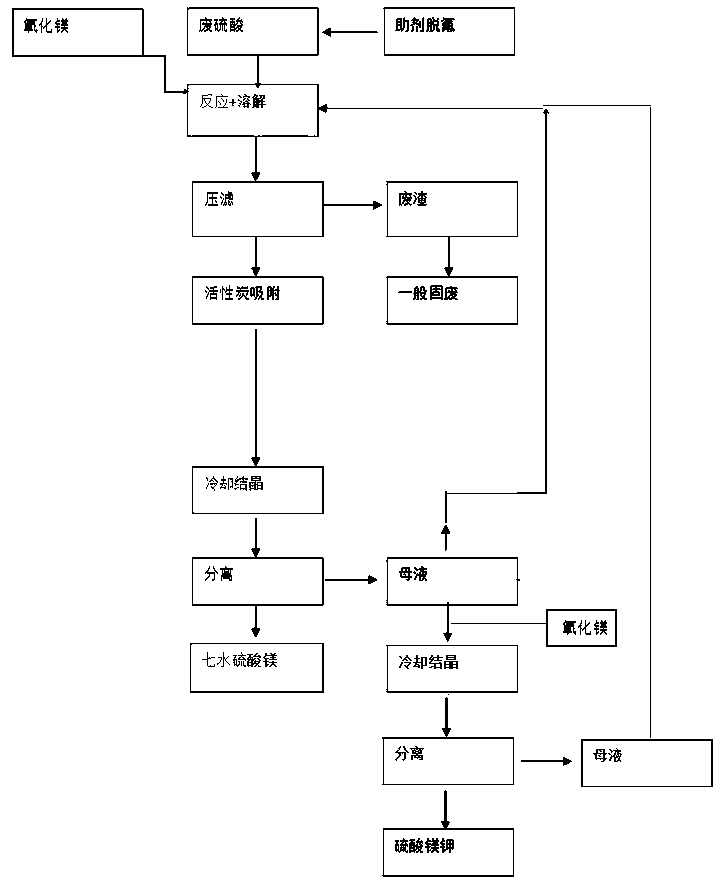

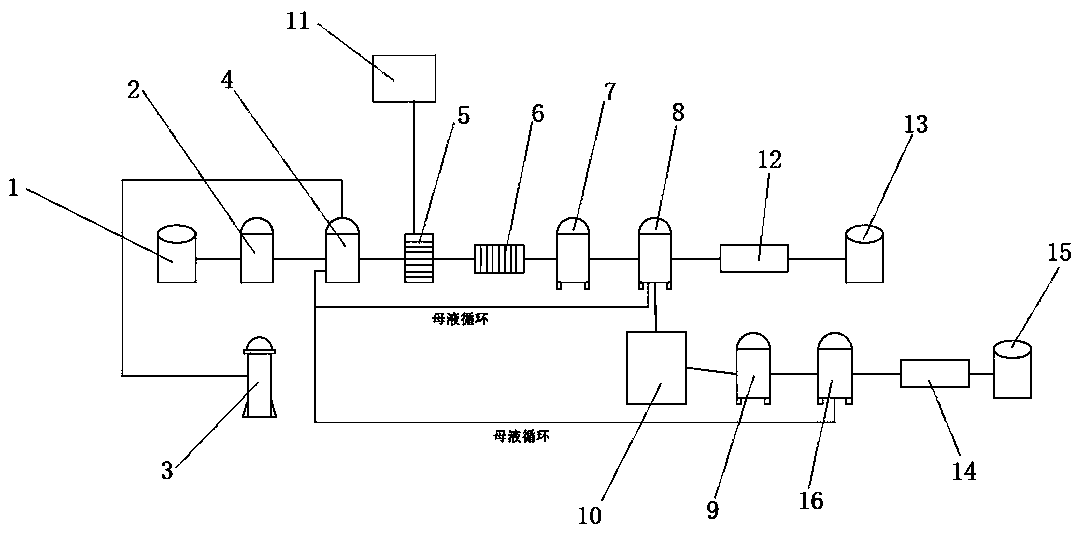

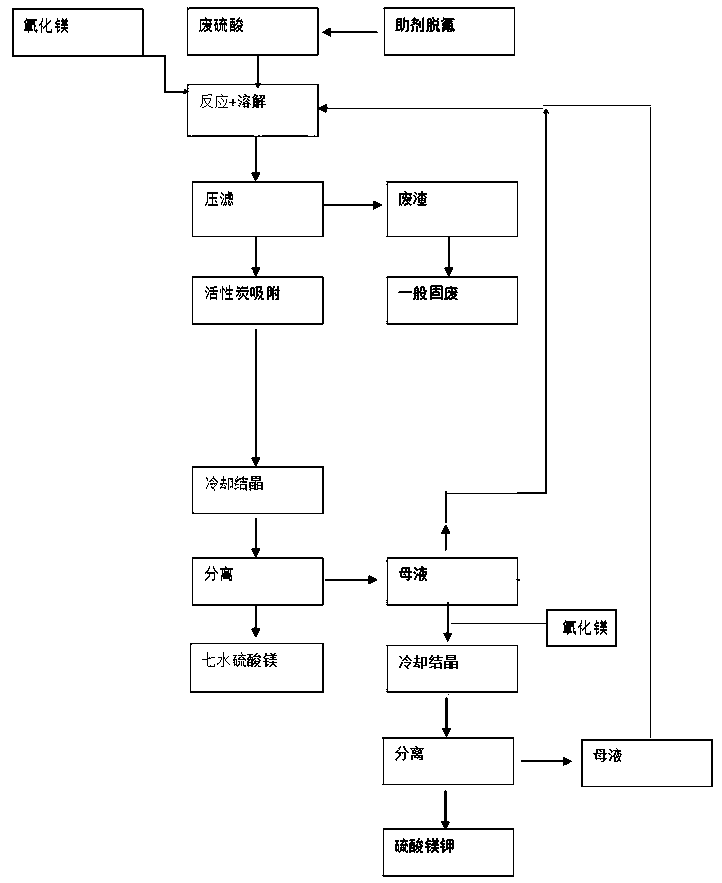

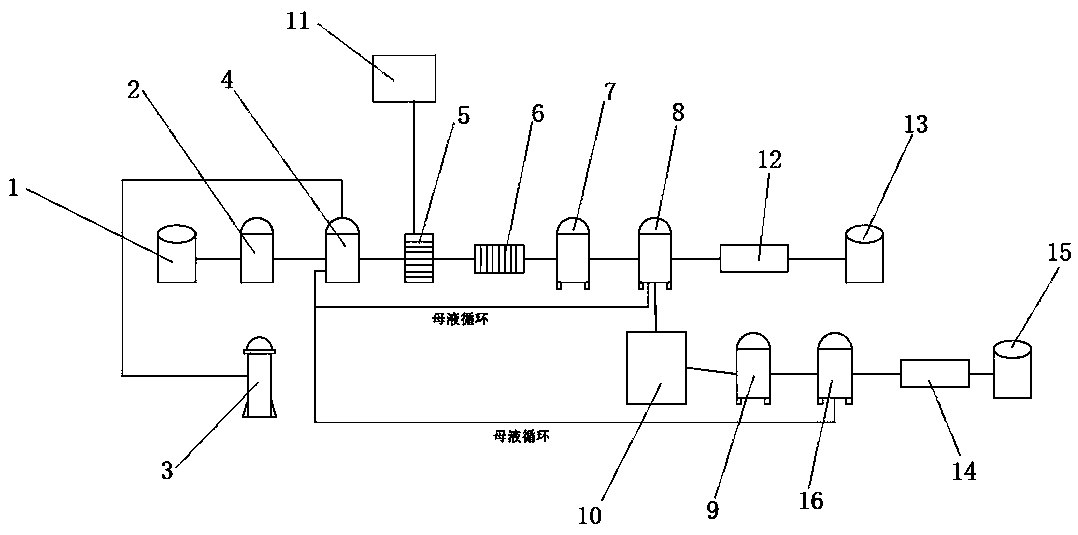

A waste sulfuric acid recycling device and process

ActiveCN110963510BAchieve recyclingIncrease concentrationDouble sulfate preparationSulfate/bisulfate preparationActivated carbon filtrationPotassium bisulfate

The invention relates to a recovery and treatment method of waste sulfuric acid, comprising S1: performing defluorination pretreatment on waste sulfuric acid; S2: transferring waste sulfuric acid to a reaction kettle, adding magnesium oxide for reaction; S3: performing pressure filtration on the reaction solution, and transferring the waste residue to Waste residue storage tank, the filtrate is transferred to activated carbon filtration equipment; S4: The mother liquor of magnesium sulfate is separated from the first crystallization tank to detect the content of potassium bisulfate. According to whether the content of potassium bisulfate in the mother liquor reaches the predetermined threshold, it is decided whether the mother liquor should continue to circulate or recover sulfuric acid Potassium hydrogen is recycled. The method and device of the present invention can realize the recovery of potassium hydrogensulfate in waste sulfuric acid, and through the circular purification of the mother liquor, when the concentration of potassium hydrogensulfate in the mother liquor does not reach the threshold value, the mother liquor is returned to the reactor to continue to increase the potassium hydrogensulfate of the mother liquor Concentration, when the concentration of potassium bisulfate in the mother liquor reaches the threshold, the mother liquor is transferred to the crystallization tank, magnesium oxide is added to generate potassium magnesium sulfate and the material is separated and discharged, realizing the low-cost recovery of potassium bisulfate in waste sulfuric acid.

Owner:山东齐创石化工程有限公司

Device and process for recycling waste sulfuric acid

ActiveCN110963510AAchieve recyclingIncrease concentrationDouble sulfate preparationSulfate/bisulfate preparationHydrogen SulfateActivated carbon filtration

The invention relates to a method for recycling waste sulfuric acid. The method comprises the following steps: S1, carrying out defluorination pretreatment on waste sulfuric acid; S2, transferring thewaste sulfuric acid into a reaction kettle, and adding magnesium oxide for reaction; S3, carrying out filter pressing on a reaction liquid, transferring waste residues to a waste residue storage tank, and transferring filtrate to activated carbon filtering equipment; and S4, separating a magnesium sulfate mother liquor through a first crystallization kettle, detecting the content of potassium hydrogen sulfate, and determining whether the mother liquor is continuously circulated or recycled after potassium hydrogen sulfate is recycled according to whether the content of potassium hydrogen sulfate in the mother liquor reaches a preset threshold value or not. According to the method and the device, the recovery of potassium hydrogen sulfate in the waste sulfuric acid can be realized; the mother liquor is circularly purified, when the concentration of potassium hydrogen sulfate in the mother liquor does not reach a threshold value, the mother liquor flows back to the reaction kettle to continue to increase the concentration of potassium hydrogen sulfate in the mother liquor, and when the concentration of potassium hydrogen sulfate in the mother liquor reaches the threshold value, themother liquor is transferred to the crystallization kettle, the magnesium oxide is added, potassium magnesium sulfate is generated, separated and discharged, and the low-cost recovery of potassium hydrogen sulfate in the waste sulfuric acid is achieved.

Owner:山东齐创石化工程有限公司

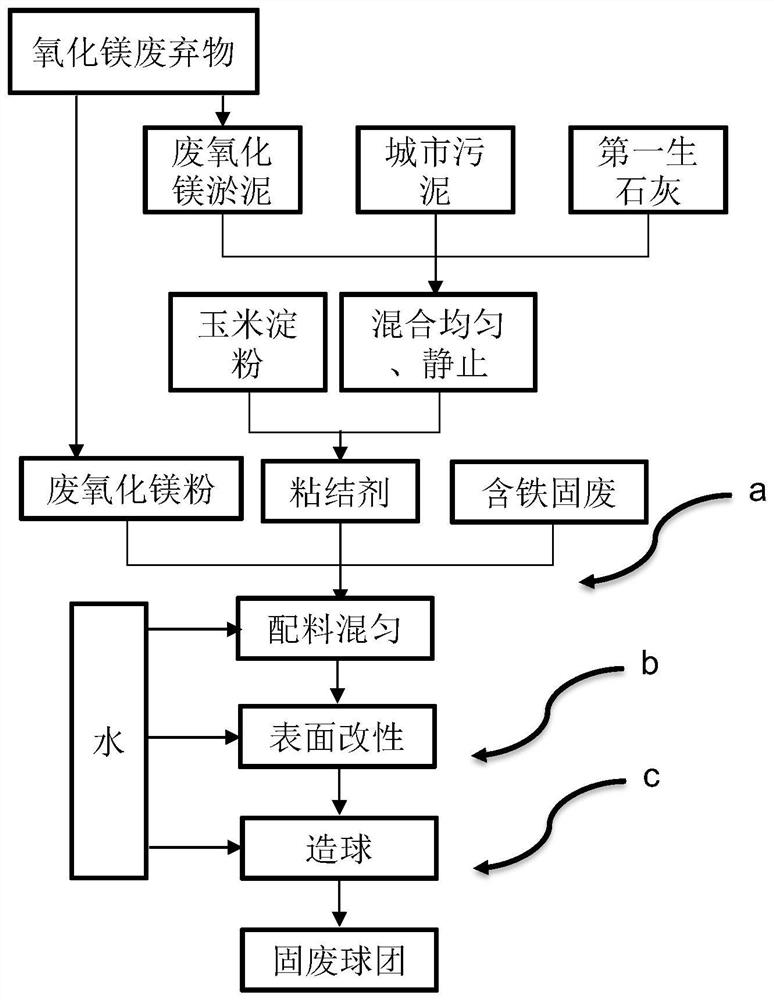

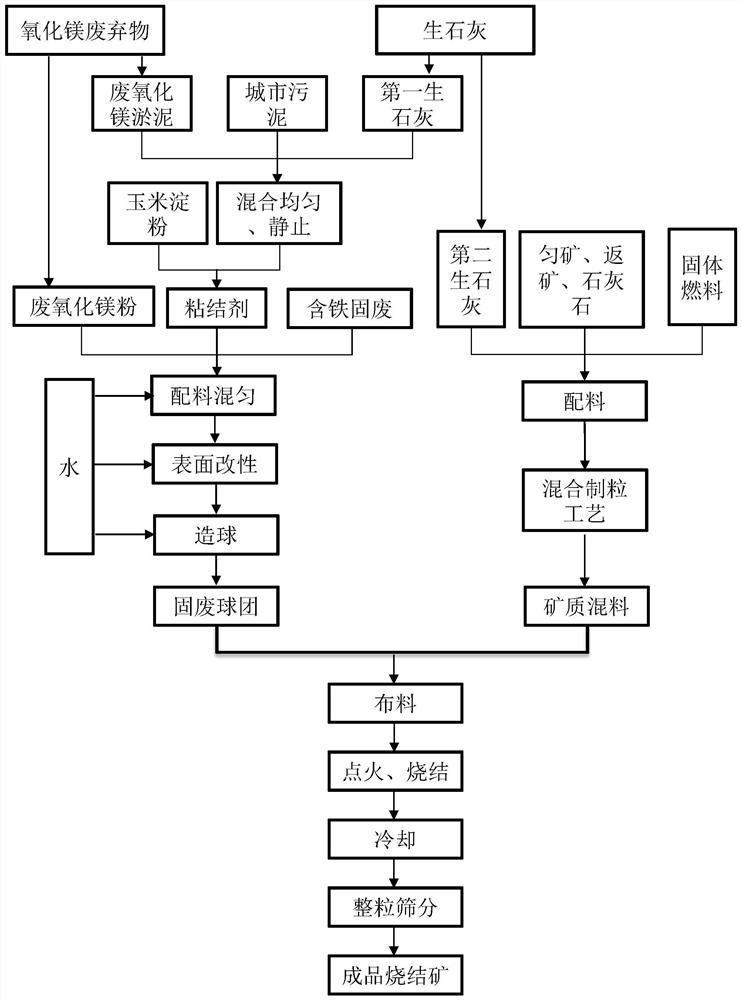

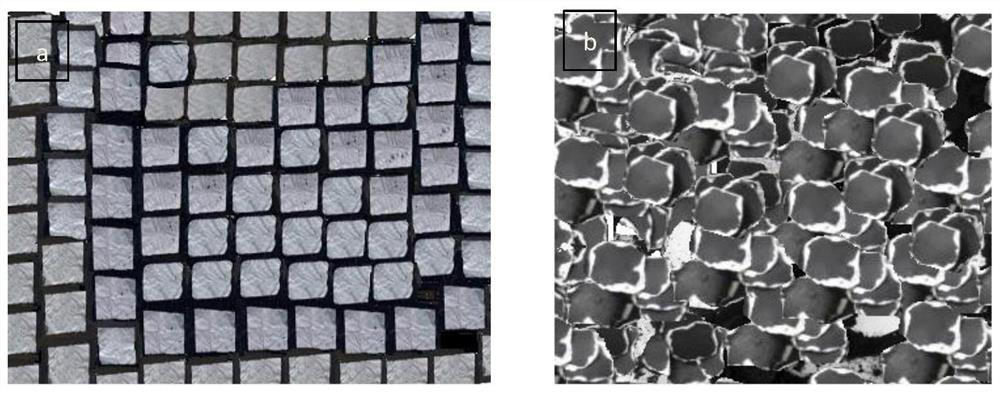

Solid waste pelletizing process and efficient sintering method thereof

PendingCN114763581AHigh thermal strengthAvoid sinter productivity impactProcess efficiency improvementFine powderCorn starch

The invention discloses a solid waste pelletizing process and an efficient sintering method thereof, waste magnesium oxide powder, iron-containing solid waste and a binder are adopted as raw materials, and solid waste pellets are prepared after burdening, surface modification and pelletizing; and mixing the solid waste pellets and a mineral mixture prepared by adopting a mixing granulation process as sintering raw materials, and sequentially carrying out material distribution, ignition, sintering, cooling and whole grain screening to obtain a finished product of sintered ore, the binder is prepared from waste magnesium oxide sludge, municipal sludge, first quick lime and corn starch; the waste magnesium oxide powder and the waste magnesium oxide sludge are magnesium oxide wastes. According to the method, the magnesium oxide waste, the municipal sludge, the rotary hearth furnace fine powder and other solid wastes inside and outside the steel plant are fully recycled, local concentrated heterogeneous sintering of magnesium oxide is realized, the adverse effect of uniform distribution of MgO on the sintering productivity is avoided, the quality of solid waste pellets is improved, and the production cost is reduced. Therefore, the quality index and the heat energy utilization efficiency of the finished sinter are remarkably improved, and fuel consumption and CO2 emission are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for recovering ilmenite from vanadium-titanium-magnetite iron beneficiation tailings

ActiveCN106179720BOvercome costsHigh recovery rateWet separationMechanical material recoveryClassification methodsMagnetite

The invention discloses a method for recycling ilmenite from vanadium titano-magnetite iron dressing tailings. The method comprises the steps that the specific susceptibility of main gangue in the iron dressing tailings, the specific susceptibility of the ilmenite in the iron dressing tailings and the content of TiO2 in the iron dressing tailings are determined; when the iron dressing tailings meet the condition 1, the iron dressing tailings are subjected to first-section strong magnetic separation, first-section strong magnetism concentrates are subjected to one-time or multi-time reselection, and gravity concentrates are obtained; the gravity concentrates are subjected to first-time flotation and one-time or multi-time electric separation, and ilmenite concentrates are obtained, wherein the condition 1 can be shown in the formula: X1>(X2*60%), the total amount of the iron dressing tailings serves as a standard, the content of the TiO2 in the iron dressing tailings is lower than 5 wt%, X1 is the specific susceptibility value of the main gangue in the iron dressing tailings, and X2 is the specific susceptibility value of the ilmenite in the iron dressing tailings; and otherwise, the iron dressing tailings are subjected to a strict granularity classification method. By mean of the method, the production cost of the ilmenite is reduced, and the grade of the TiO2 of selected raw ore obtained after electric separation and flotation is improved.

Owner:PANGANG GRP MINING

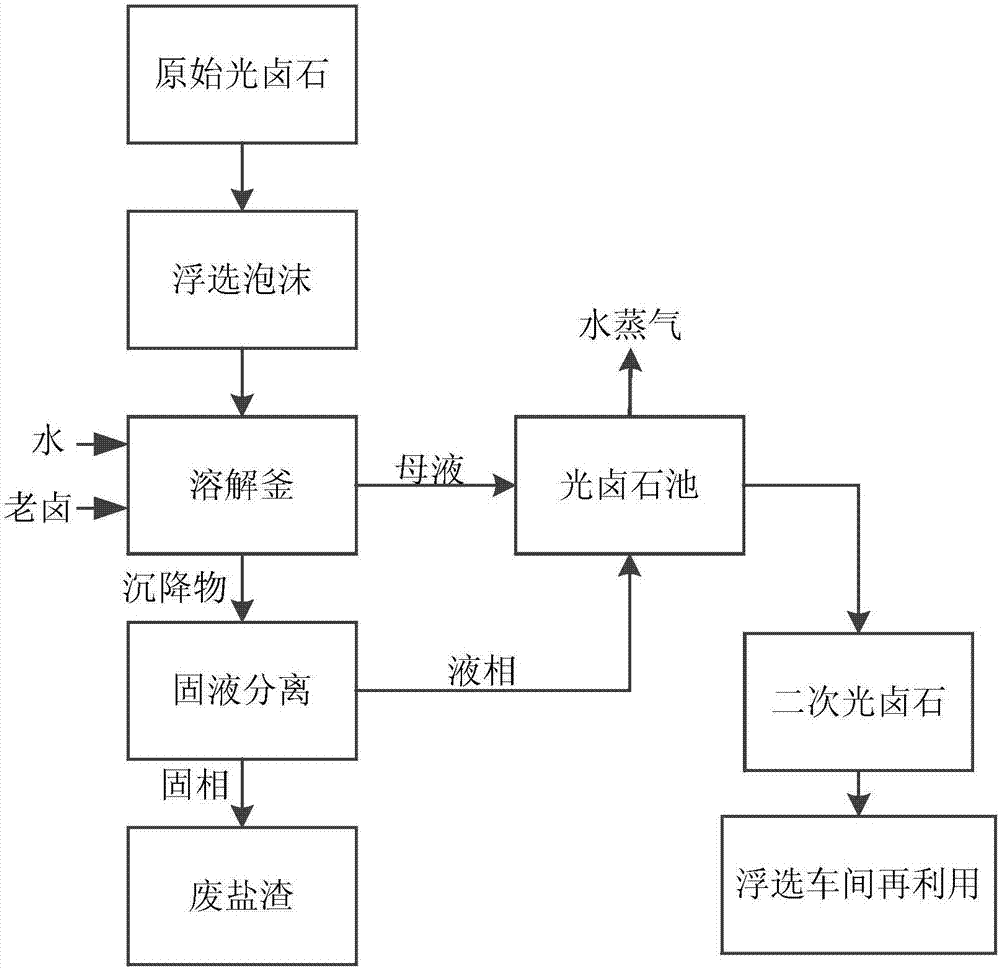

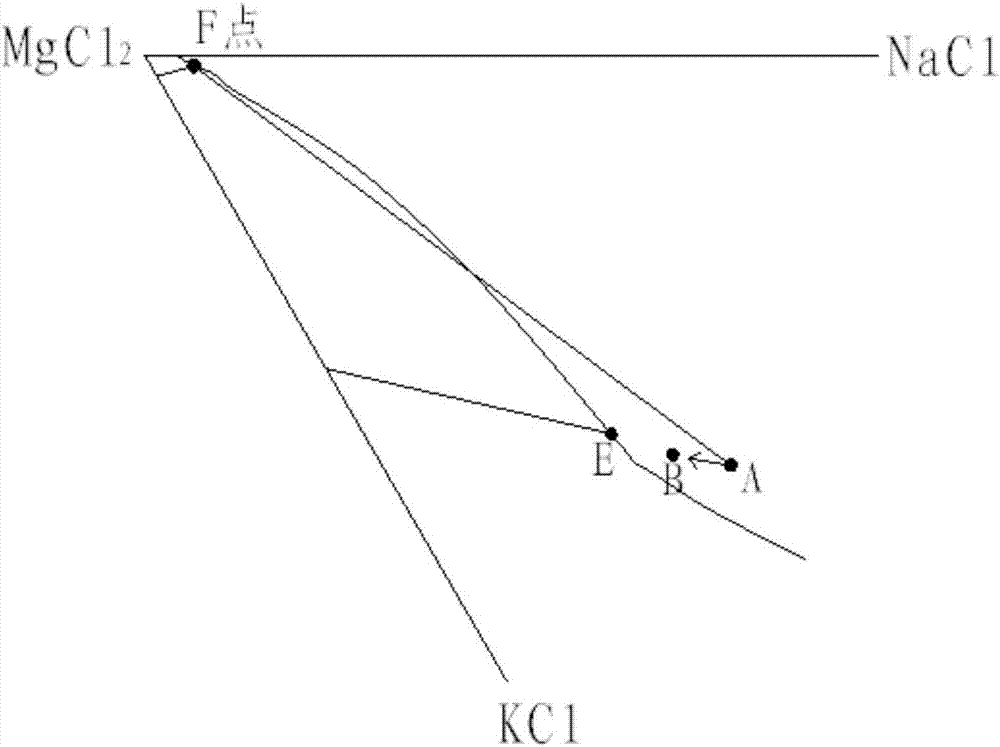

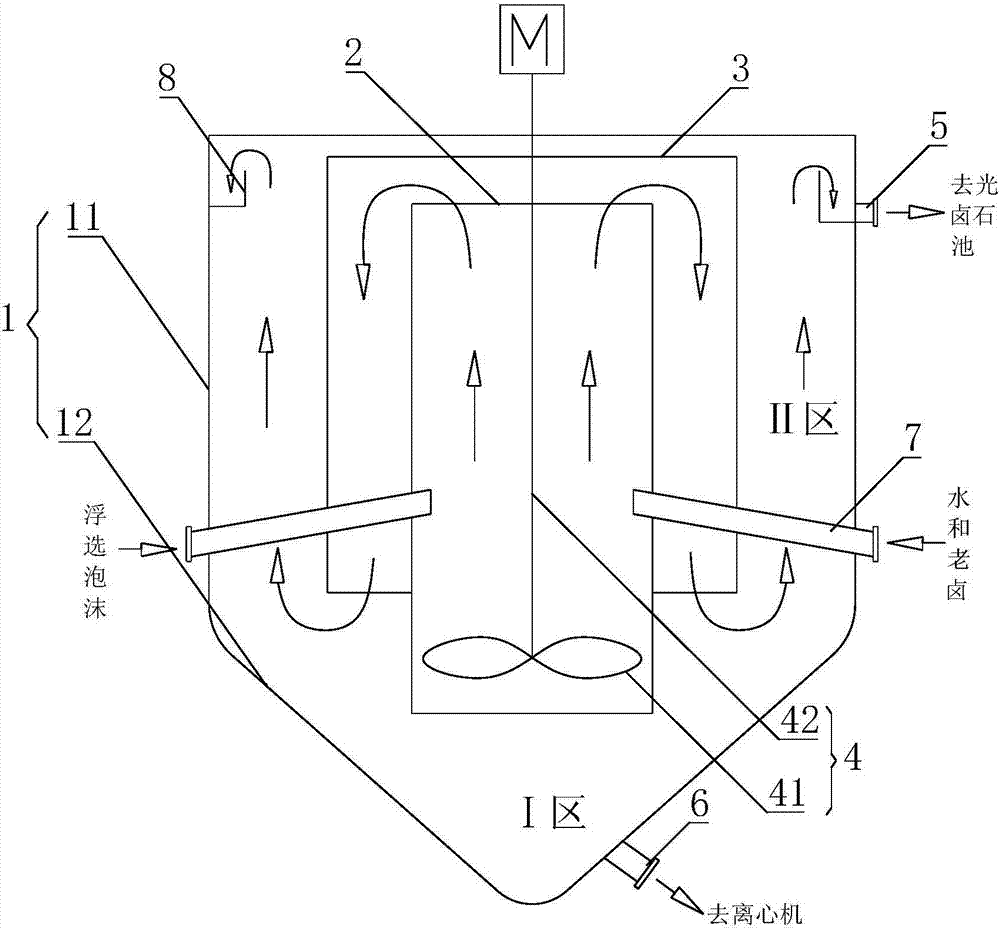

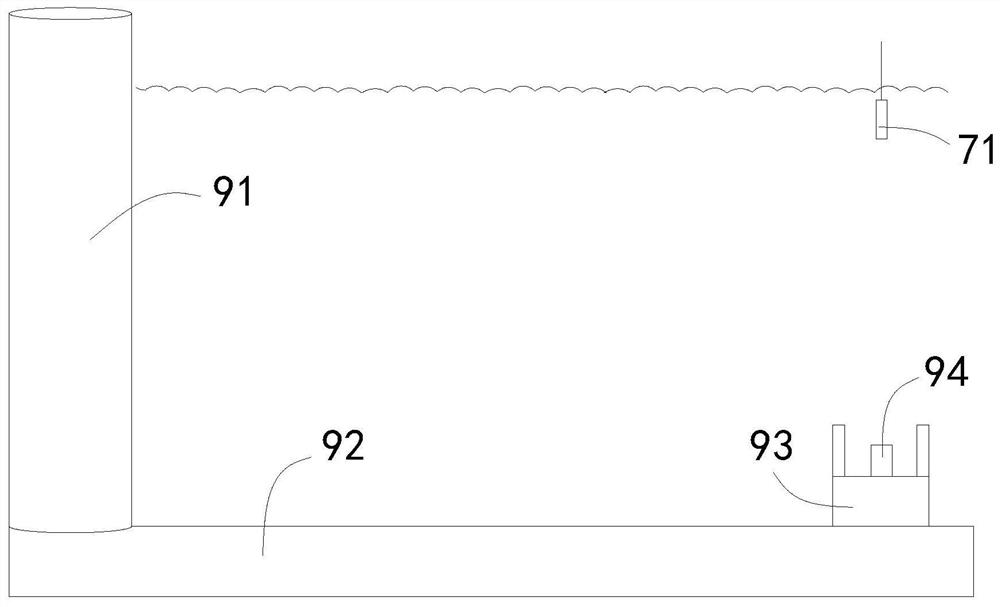

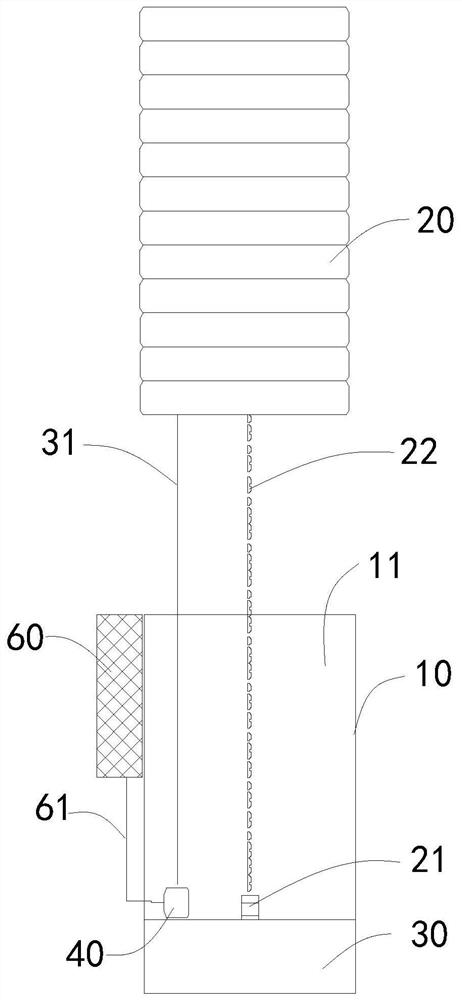

A method for separating potassium chloride in flotation froth and a dissolution kettle

ActiveCN105948077BImplement extractionAchieve the purpose of separationAlkali metal chloridesPotassiumFresh water

The invention discloses a method for separating potassium chloride in flotation froth and a stirring vessel. The method comprises the steps that the flotation froth is input into the stirring vessel which can enable the flotation froth to flow vertically and mixed with water and old brine, solid potassium chloride in the flotation froth is dissolved, sodium chloride solid particles are sedimented, a mother solution with potassium chloride is dried in air to be separated out, and the main component is secondary carnallite containing potassium chloride. The stirring vessel applying the method comprises a vessel body, a stirrer, a center barrel and a flow guiding barrel, wherein the stirrer, the center barrel and the flow guiding barrel are sequentially arranged from interior to exterior in a sleeved mode. A mother solution outlet is formed in the upper portion of the vessel body, a sedimentation outlet is formed in the lower portion of the vessel body, the first end of at least two feeding pipes arranged in the stirring vessel is arranged inside the center barrel. The stirring vessel is combined with the method, so that potassium chloride in reverse flotation froth can be efficiently extracted; compared with a traditional method for recycling potassium chloride in reverse flotation froth, the efficiency is higher, the process is shorter, the cost is lower, the fresh water consumption is smaller.

Owner:QINGHAI SALT LAKE IND

Method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water

The invention discloses a method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water, falling into silk making technical field. The method includes subjecting common tap water to electrolytic treatment via water electrolyzer or electrolytic cell, to obtain strongly alkaline electrolyzed water with pH of 11.0-12.0; performing constant-temperature oscillation swelling soaking treatment on silkworm cocoon in strongly alkaline electrolyzed water at 60-80 DEG C directly for 5-10 min; and taking strongly alkaline electrolyzed water as reeling hot water bath, transferring the swollen silkworm cocoon to the reeling hot water bath at 40-70 DEG C, and immediately reeling silk, to obtain raw silk product. The inventive method performs reeling at low temperature, to improve product quality and save energy. The invention can realize industrial production of strongly alkaline electrolyzed water at low cost and high yield, high-efficiency low-cost recovery of sericin, and cyclic utilization of reeling waste water after simple purification treatment, to thereby avoid environmental pollution caused by a large amount of waste liquid.

Owner:SUZHOU UNIV

Remote type auxiliary anode automatic recycling device

The invention discloses a remote type auxiliary anode automatic recycling device. A containing cavity is formed in a pressure-proof protecting cylinder. An inflating type floating device, a compressedair bottle and an inflating valve are arranged in the containing cavity. The inflating valve is connected between the inflating type floating device and the compressed air bottle. The inflating valveis turned on to be used for enabling the compressed air bottle to inflate the inflating type floating device. A protecting plate seals and covers an end opening of the containing cavity. The protecting plate and the containing cavity are detachably connected. A signal receiver is fixedly connected with the pressure-proof protecting cylinder and electrically connected with the inflating valve. A signal transmitter is used for sending a recycling signal to the signal receiver, thus the signal receiver is triggered to turn on the inflating valve, the inflating type floating device in an inflation state is used for pushing the protecting plate to be popped out of the containing cavity, thus the remote type auxiliary anode automatic recycling device is driven to float up, and therefore efficient and low-cost recycling of the remote type auxiliary anode automatic recycling device is achieved.

Owner:SUN YAT SEN UNIV

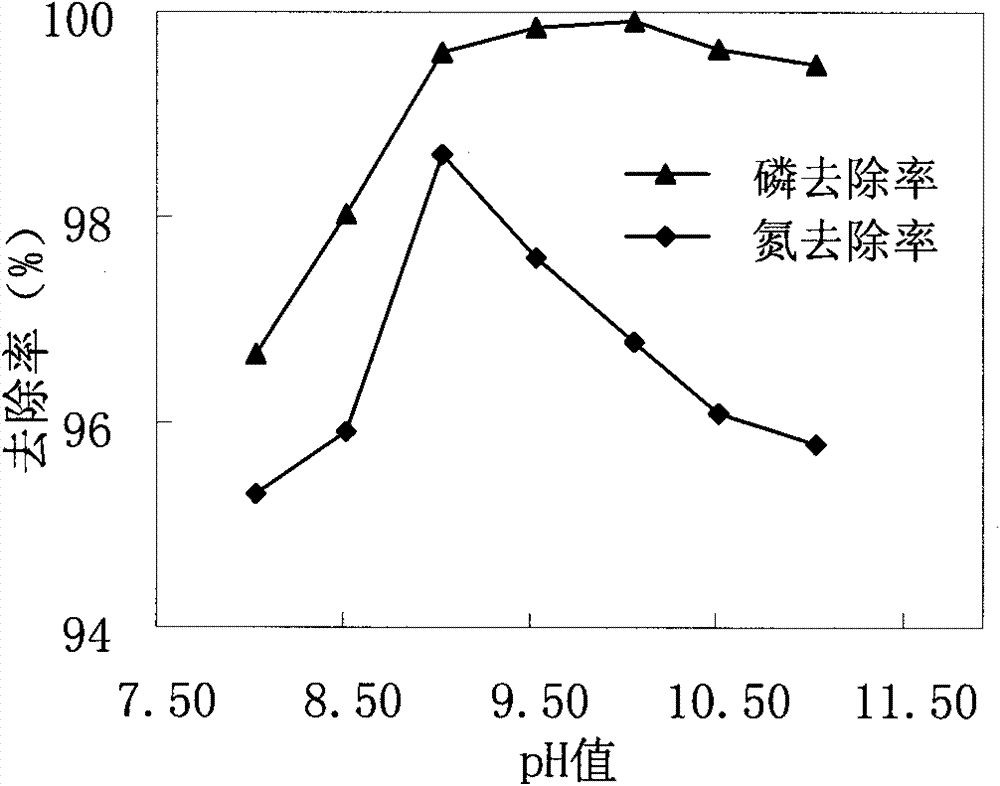

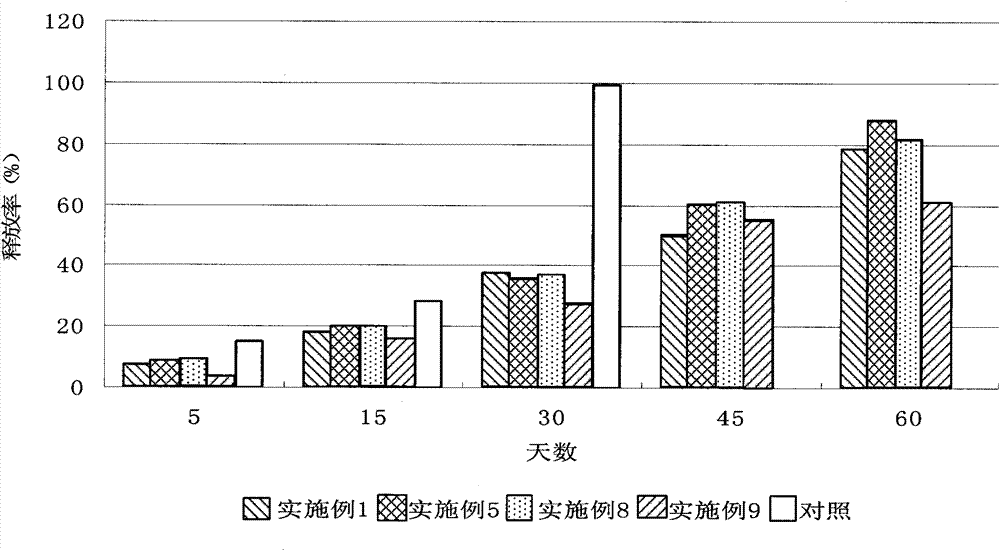

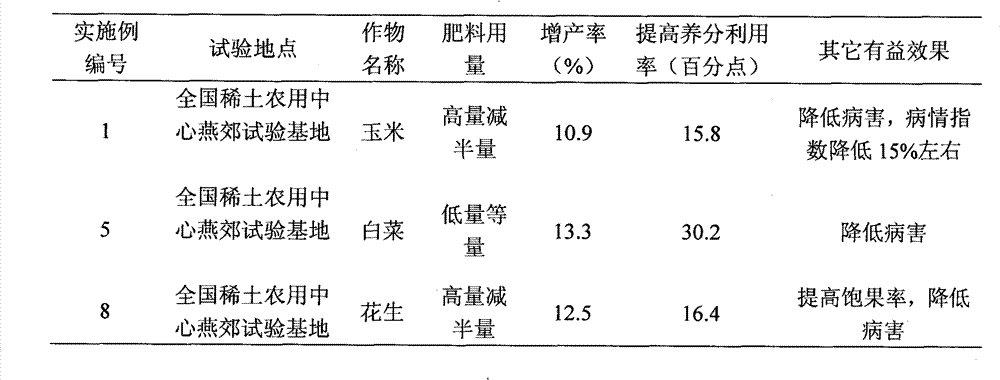

Ammonium magnesium phosphate slow release fertilizer and preparation method thereof

The invention discloses an ammonium magnesium phosphate slow release fertilizer and a preparation method thereof, belonging to the technical field of waste water treatment. The ammonium magnesium phosphate slow release fertilizer contains at least one of potassium, iron, calcium, zinc, titanium and sulfur and a rare earth, wherein the rare earth is counted on the basis of the weight of an rare earth oxide (REO); the sum of the content of at least one of the potassium, iron, calcium, zinc, titanium and sulfur and the content of the REO is 0.01-10 percent by weight; the content of P2O5 is 15-49percent by weight; the content of N is 3-10 percent by weight; and the content of MgO is 16-26 percent by weight. In the preparation method, waste water is taken as a raw material, the ammonium magnesium phosphate slow release fertilizer is provided, so that valuable resources such as nitrogen, phosphorus, rare earth, magnesium and the like in the waste water are effectively recycled at low cost,the problem of waste water pollution is solved, and the valuable resources such as nitrogen, phosphorus, rare-earth, magnesium and the like in the waste water are effectively recycled at low cost.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Process for multiple stage direct electrowinning of copper

InactiveUS20060144716A1Low cost recyclingReduce expensesPhotography auxillary processesElectrolysis componentsElectrolysisCopper

A system and process for recovering copper from a copper-containing ore, concentrate, or other copper-bearing material to produce high quality cathode copper from a leach solution without the use of copper solvent / solution extraction techniques or apparatus. A process for recovering copper from a copper-containing ore generally includes the steps of providing a feed stream containing comminuted copper-containing ore, concentrate, or other copper-bearing material, leaching the feed stream to yield a copper-containing solution, conditioning the copper-containing solution through one or more physical or chemical conditioning steps, and electrowinning copper directly from the copper-containing solution in multiple electrowinning stages, without subjecting the copper-containing solution to solvent / solution extraction prior to electrowinning.

Owner:FREEPORT MCMORAN COPPER & GOLD INC

Cooling tower airflow generating set

The invention relates to a cooling tower airflow generating set which comprises a high temperature steam pipeline, a cold water spraying head, a flow board, an inclined cover plate, a flow guiding plate and a hot air generating set, wherein the high temperature steam pipeline is arranged at the lower part of a cooling tower and above an air inlet in the lower part of the cooling tower; the cold water spraying head is arranged in the cooling tower and above the high temperature steam pipeline, and faces the high temperature steam pipeline; the flow board is fixed in channel steel fixed in the top of the cooling tower in a downwards-inclined manner through a fixing device; a circle of flow guiding plate is arranged on the inclined cover plate; and the hot air generating set is arranged in the center of the inclined cover plate. The high temperature steam pipeline is sprayed through the cold water spraying head, the spraying is combined with the air inversed flow to produce a large amount of hot steam, and the hot steam is converted into electric energy, so that the heat energy produced in exhausting steam of the cooling tower is recovered and used at a low cost, and the generating set is recycled and very practical.

Owner:洛阳希诺能源科技有限公司

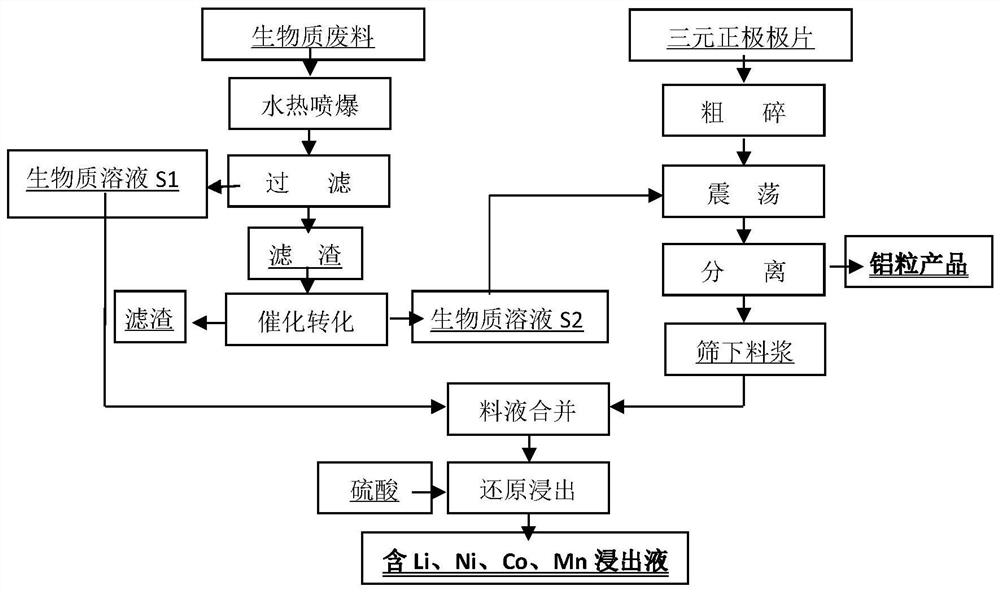

A method for the full recovery of valuable metal elements in the positive pole pieces of waste power lithium batteries

ActiveCN111411232BRealize full recyclingReduce processing costsWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryAluminum metal

The invention discloses a method for full amount recovery of valuable metal elements in an anode piece of a waste power lithium battery. The method includes the steps that in advance, a hydrothermal reaction of biomass under a weak acid condition is carried out, a biomass solution S1 and filter residue are obtained by separation, then the filter residue reacts in an alkaline solution, and a biomass solution S2 is obtained by separation; the waste anode piece is stripped in the biomass solution S2, aluminum metal and anode paste are obtained by separation; and then, the anode paste and the biomass solution S1 are reduced and leached in an acid solution to obtain a leaching solution enriched with Li, Ni, Co and Mn. According to the method, Al is separated as metal, the efficient leaching ofLi, Ni, Co and Mn can be realized, and the full amount recovery of waste ternary materials with low cost and high efficiency can be realized.

Owner:湖南烯富环保科技有限公司

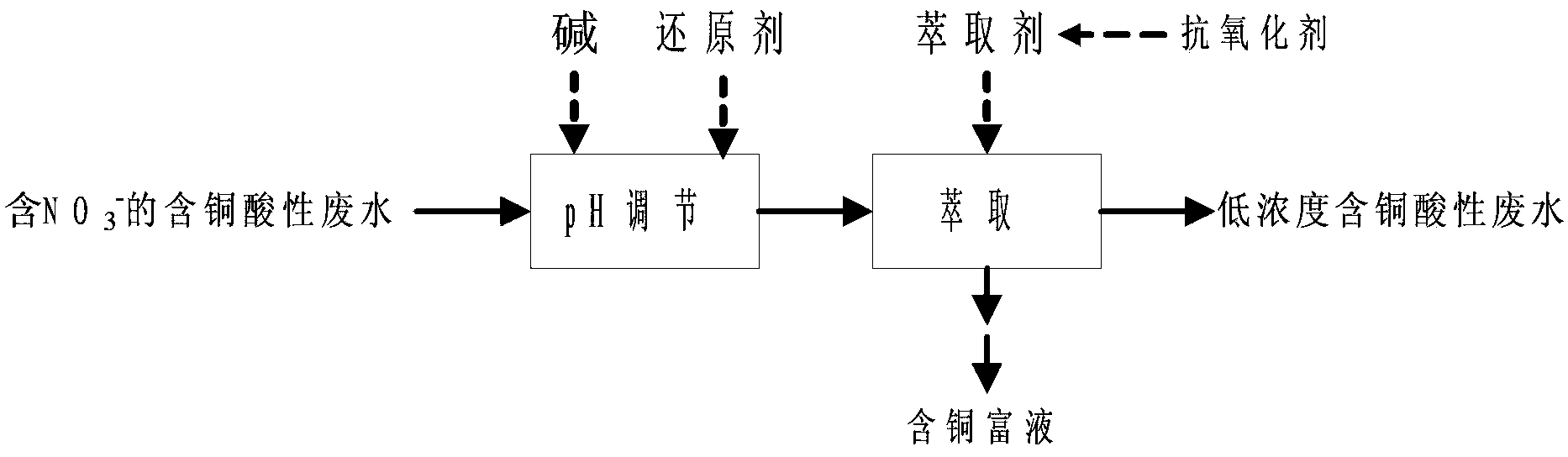

Method for reducing consumption of copper extractant in copper extraction process by nitric acid system

ActiveCN103194601BReduce consumptionReduce oxidationProcess efficiency improvementPhase splittingWastewater

The invention relates to a method for reducing the consumption of a copper extractant in a copper extraction process by a nitric acid system. By adopting the method, the problems of interphase substance increase, difficult phase splitting, low extraction efficiency, large extractant consumption and the like caused by the oxidative deterioration of the extractant are avoided to the greatest extend mainly by reducing the oxidability of an extraction solution and improving the oxidation resistance of the extractant, so as to reduce the consumption of the extractant in the nitric acid system and to realize the efficient and low-cost recycling treatment of the copper containing acidic wastewater.

Owner:ZIJIN MINING GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com