Remote type auxiliary anode automatic recycling device

An auxiliary anode and automatic recovery technology, applied in the field of marine engineering, can solve problems such as difficulty in recycling remote auxiliary anodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

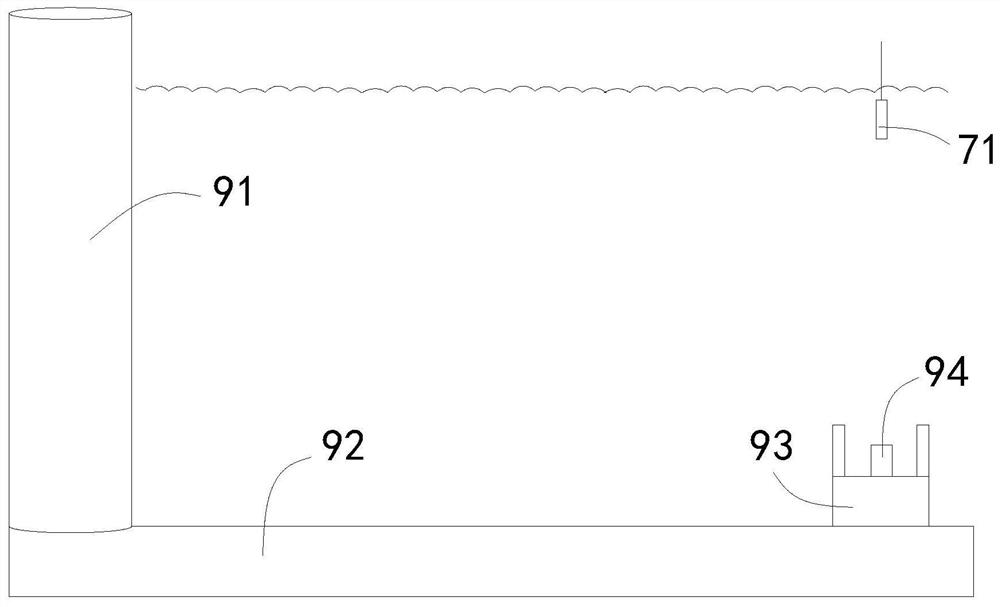

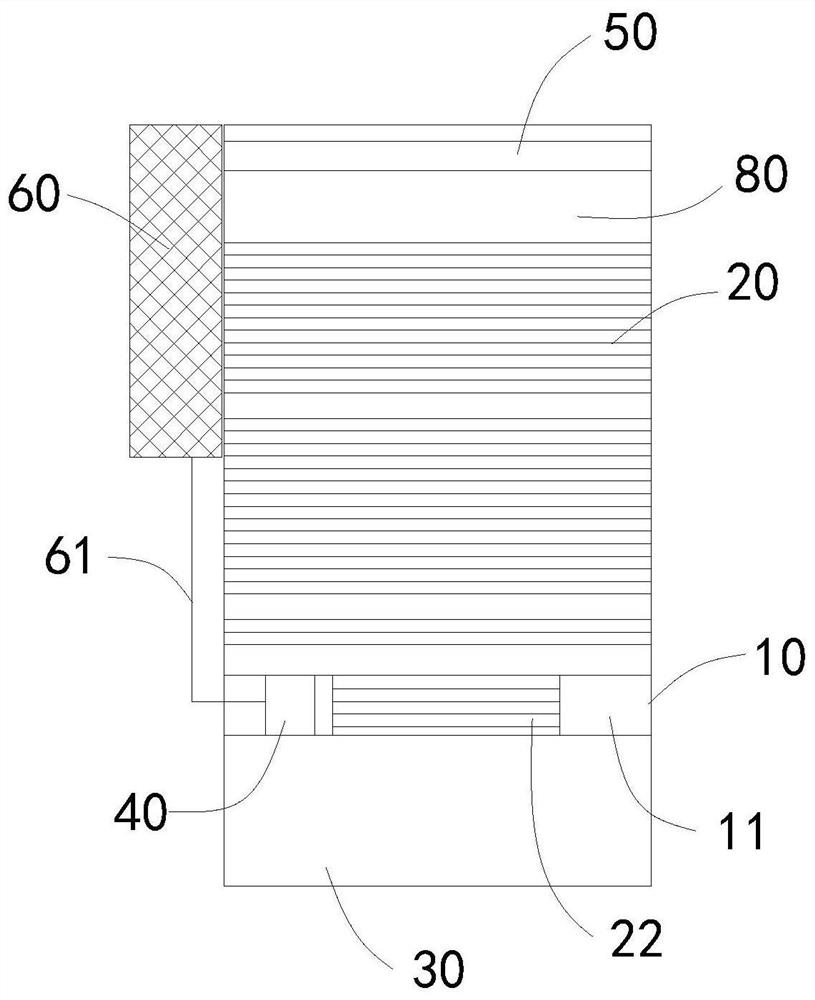

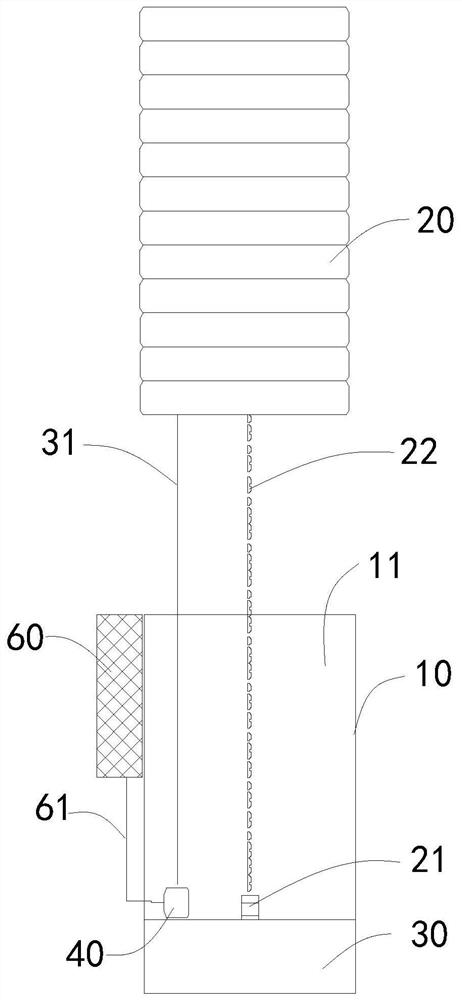

[0034] Such as Figure 1 to Figure 3 As shown, the present invention provides a remote auxiliary anode automatic recovery device 94, comprising a pressure-resistant protective cylinder 10 (its structural material can be steel, glass fiber reinforced plastic, or other high-strength non-metallic pressure-resistant materials), an inflatable Floater 20 (can be made of rubber or other engineering plastics), compressed gas cylinder 30, inflation valve 40 (such as solenoid valve), protection plate 50, signal receiver 60 and signal transmitter 70; The storage cavity 11 is provided with an inflatable floater 20, a compressed gas cylinder 30 and an inflation valve 40 in the storage cavity 11, and an inflation valve 40 is connected between the inflatable floater 20 and the compressed gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com