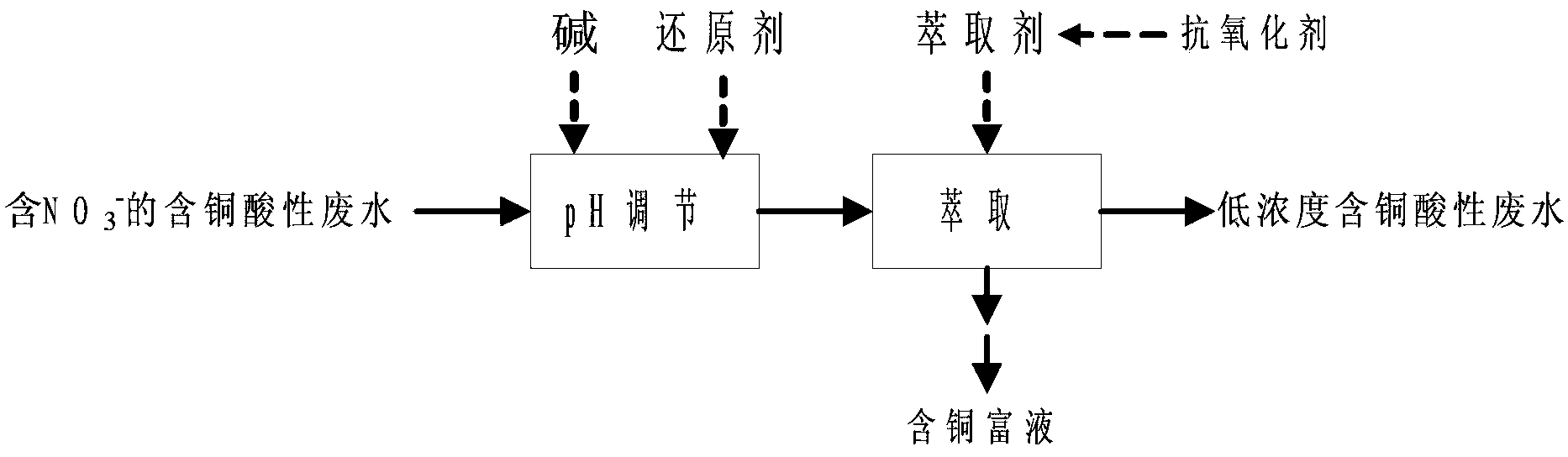

Method for reducing consumption of copper extractant in copper extraction process by nitric acid system

A copper extractant and a technology for extracting copper are applied in the field of reducing the consumption of copper extractant in the process of extracting copper by a nitric acid system, and can solve the problems of difficult phase separation, large consumption of extractant, easy oxidation and deterioration of extractant, etc., so as to reduce consumption The effect of high-volume, low-cost recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Adopt the method disclosed in the present invention to first add lime to adjust the pH value of the purified waste water, so that the pH value is adjusted to 2.0, then add sodium dithionite according to the dosage of 50 mg / L, and use the method disclosed in the present invention to increase the pH value by 15% per liter Add 50mg2,6-di-tert-butyl p-cresol to the vol copper extractant. Through continuous extraction test, it is determined that the consumption of copper extractant is about 6.0 kg / ton of copper, the complete phase separation time of extraction is less than 60s, the recovery rate of copper in wastewater is greater than 96%, and the comprehensive treatment cost of wastewater is less than 15 yuan / ton of water.

Embodiment 2

[0022] Adopt the method disclosed in the present invention to first add lime to adjust the pH value of the purified waste water to adjust the pH value to 2.8, then add sodium dithionite according to the dosage of 150 mg / L, and use the method disclosed in the present invention to increase the pH value by 20% per liter Add 100mg2,6-di-tert-butyl p-cresol to the vol copper extractant. Through continuous extraction test, it is determined that the consumption of copper extractant is about 5.8 kg / ton of copper, the complete phase separation time of extraction is less than 60s, the recovery rate of copper in wastewater is greater than 96%, and the comprehensive treatment cost of wastewater is less than 15 yuan / ton of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com