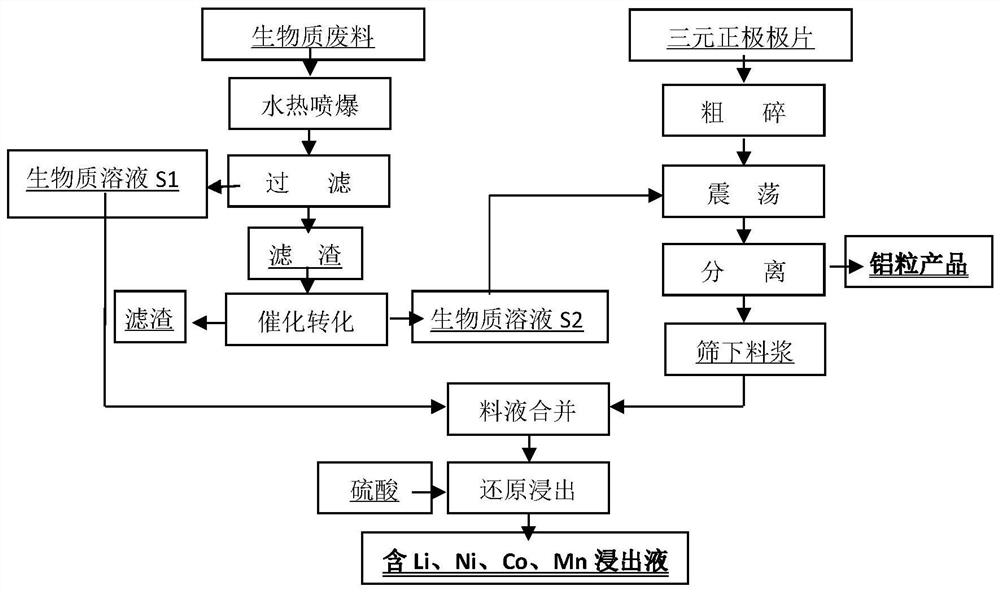

A method for the full recovery of valuable metal elements in the positive pole pieces of waste power lithium batteries

A positive pole piece and metal element technology, which is applied in the field of full recovery of valuable metal elements in the positive pole piece of waste power lithium batteries, can solve the problem of high processing costs, difficult full leaching of valuable elements, and difficult metal state recovery of aluminum collectors and other problems to achieve the effect of reducing the difficulty of impurity removal and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Example 1, the recovery of the full amount of valuable metal elements in the positive pole piece of the waste power lithium battery with the assistance of biomass waste corn cob.

[0054] The corn cobs used in this example have been crushed to pass through a 200-mesh sieve before use. The concrete implementation procedure of this embodiment is:

[0055] Process 1:

[0056] Step 1: Add corncobs to a volumetric concentration (V 硫酸 / V 水 ) in 2% dilute sulfuric acid to prepare a slurry with a liquid-solid ratio of 1.2:1. After soaking at room temperature for 12 hours, place the slurry in a closed reaction kettle and keep it warm at 105°C for 30 minutes, then open the discharge of the reaction kettle. Valve, so that the slurry is sprayed and exploded from the reactor to the explosion chamber outside the reactor, and the slurry after hydrothermal treatment is obtained, and the biomass solution S1 and the filter residue are obtained by filtration;

[0057] Step 2: Place th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com