A method for recovering ilmenite from vanadium-titanium-magnetite iron beneficiation tailings

A technology for ilmenite and tailings, which is applied in the field of recovering ilmenite from vanadium-titanium magnetite iron beneficiation tailings, and can solve the problems of high cost and low recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

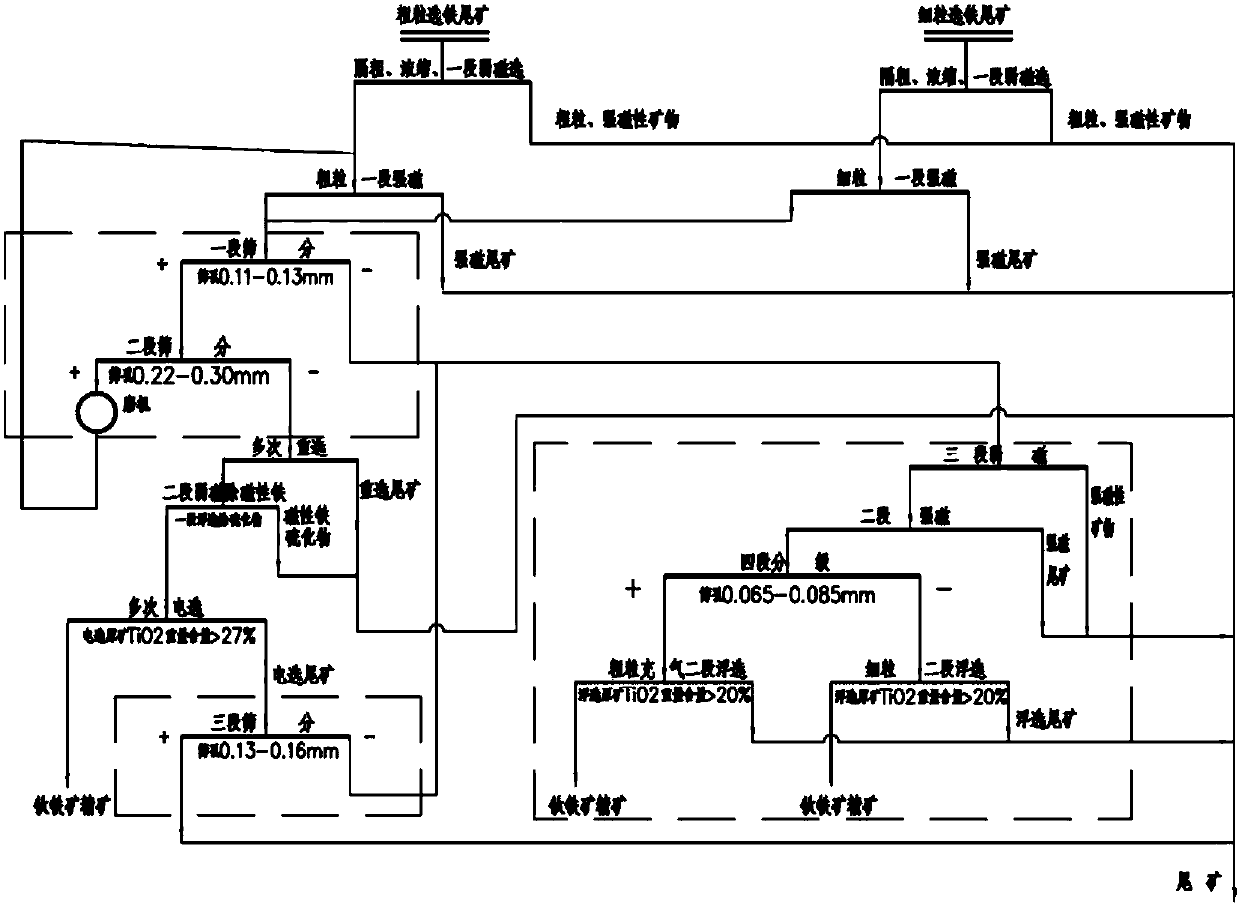

Method used

Image

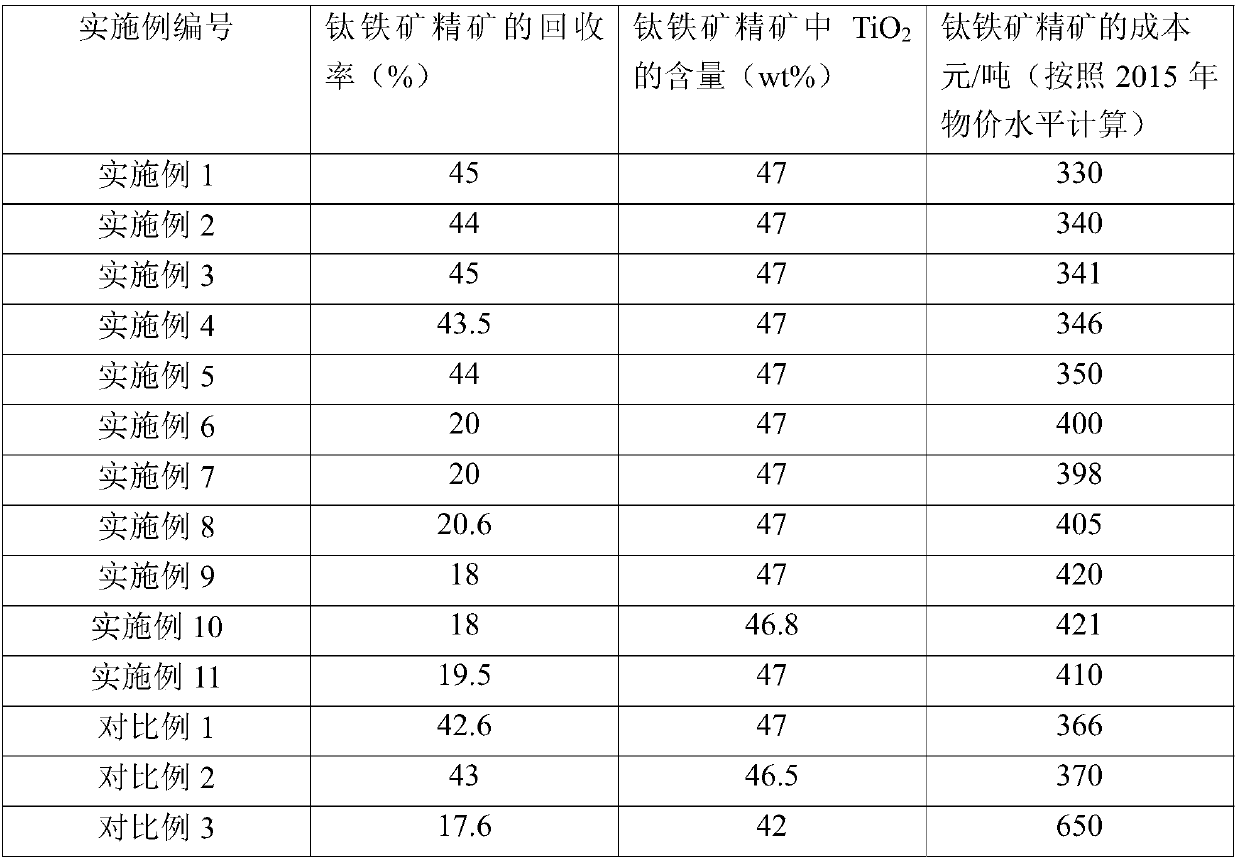

Examples

Embodiment 1

[0105] What is adopted is the vanadium-titanium magnetite iron tailings (hereinafter referred to as the first raw material ore) taken from the Panzhihua mining area, and the main components of the first raw material ore obtained by the chemical element analysis (titration) method and each group are detected. The content (100 wt %) of the ingredients is shown in Table 1. Among them, TFe represents the total content of iron.

[0106] Table 1

[0107] component

TFe

TiO 2

S

Content (wt%)

14

9.75

0.54

[0108] In addition, based on the total amount of the first raw material ore, the content of minerals with a particle size of 0.075 mm or more in the iron dressing tailings is 50% by weight.

[0109] The specific magnetic susceptibility of the main gangue in the first raw material ore is 100×10 -6 cm 3 / g, the specific magnetic susceptibility of ilmenite is 256×10 -6 cm 3 / g, where the main gangues include titanium pyroxene, plagioclas...

Embodiment 2

[0120] The recovery of ilmenite is carried out according to the method of Example 1, except that, in step (2), a 0.11 mm high-frequency fine sieve is used instead of a 0.12 mm high-frequency fine sieve.

Embodiment 3

[0122] The recovery of ilmenite is carried out according to the method of Example 1, except that in step (4), a 0.22mm high-frequency fine sieve is used instead of a 0.25mm high-frequency fine sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com