Method for reeling silk at low temperature by utilizing strongly alkaline electrolyzed water

A technology of electrolysis of water and strong alkalinity, which is applied in the fields of silk reeling, textiles and papermaking, and mechanical treatment. It can solve the problems of electrolysis water research and application that have not been reported, and achieve the purpose of improving electrolysis efficiency, avoiding environmental pollution, and high-efficiency recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of strong alkaline electrolyzed water

[0025] The present invention is based on the principle of electrolysis of water-chemical reaction, water is a weak electrolyte, and there is an ionization balance inside, and the balance formula is expressed as:

[0026] ①H 2 O = H (+) + OH (-)

[0027] ②H (+) + OH (-) = H 2 o

[0028] v① = v② v is the reaction speed;

[0029] Under the action of direct current, hydrogen and oxygen are released, and the hydrogen ions and hydroxide ions are continuously reduced, breaking the equilibrium system and making the water continuously ionized, and v①>v②, so that the reaction can continue.

[0030] Anode reaction: 4OH (-) -4e (-) = 2H 2 O+O 2 ↑

[0031] Cathode reaction: 2H(+)+2e(-) = H 2 ↑

[0032] Total reaction: 2H 2 O=(power on)2H 2 ↑+O 2 ↑

[0033] water (H 2 O) is electrolyzed to generate electrolyzed water. Current passing through water (H 2 O), oxygen is formed at the anode and hydrogen is for...

Embodiment 2

[0041] 1. Silk reeling with strong alkaline electrolyzed water (low temperature reeling)

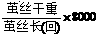

[0042] In this example, the strong alkaline electrolyzed water prepared in Example 1 is used to reel a grain of silk using a new silk reeling process. The process steps and conditions are as follows: select a cocoon shell with a uniform texture, and place it at a pH of 11.50 with a bath ratio of 1. : 40 strong alkaline electrolyzed water, in a water-bath shaker with a temperature of 70 °C and a rotation speed of 120 rpm, immerse silkworm cocoons for 5-7 minutes; take out the treated silkworm cocoons and place them at 50-70 °C , pH11.50 warm water for constant temperature reeling. When reeling, according to the sequence of silk fibers, one strand is formed every 100 times, and then the strands are interlocked in sequence, the first to tenth strands are interlocked in sequence, so as not to disturb the order of silk fibers, and obtain the cocoon of silk reeling under low temperature condit...

Embodiment 3

[0057] Preparation of strong alkaline electrolyzed water with electrolysis accelerator:

[0058]In this embodiment, the electrolytic cell is used to feed ordinary tap water containing 0.01% NaCl electrolyte promoter, the DC power supply is turned on to make the electrolytic cell work, the alkaline electrolyzed water at the cathode outlet is collected, and the current or tap water flow rate is adjusted to obtain a pH of 12.10. After the electrolyzed water is filtered or left standing overnight, the filtrate or supernatant is used for all experiments of the present invention. The specific experiment is as follows: tap water is directly passed into the electrolytic cell for electrolysis, and 50L of ordinary tap water (~pH8.04) is used to produce 25L of acidic electrolyzed water (pH2.50) and 25L of alkaline electrolyzed water (pH12.10).

[0059] The silk reeling process provided in Example 2 is used for reeling to obtain silk raw silk, and the reeling results meet the quality requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com