Dedusting method and system for coal moisture control

A technology of dust removal system and coal humidity control, applied in the field of dust removal system, can solve the problems of sticky material blockage of ash discharge system equipment, flammability and explosion of coal humidity control and dust removal, and easy condensation of flue gas, so as to achieve smooth ash discharge and easy removal Explosive and easy to raise dust, the effect of guaranteed system safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

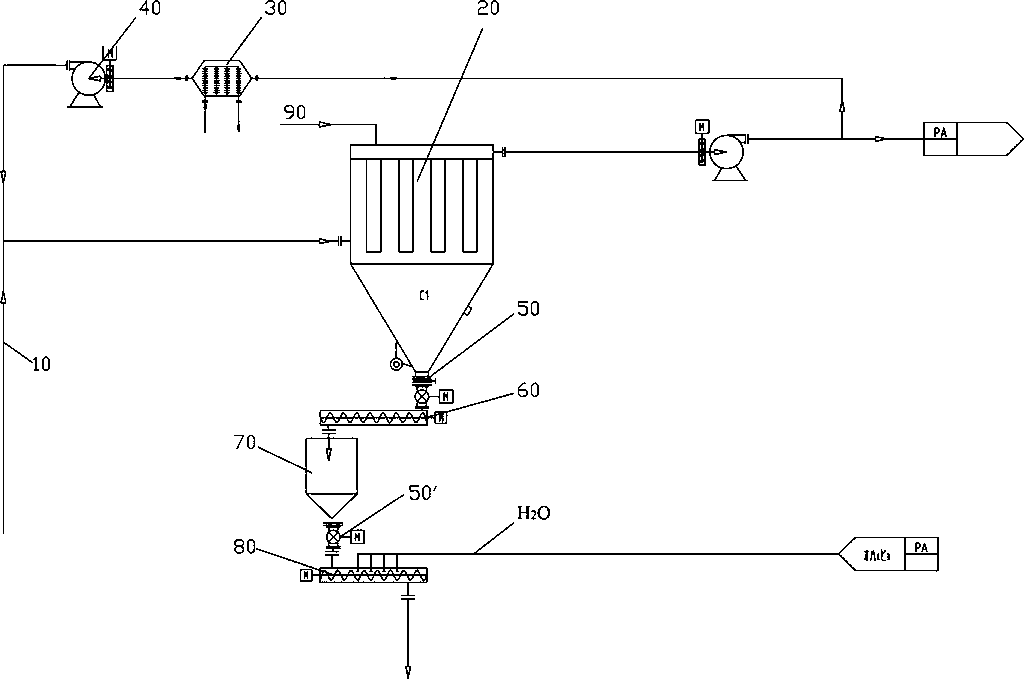

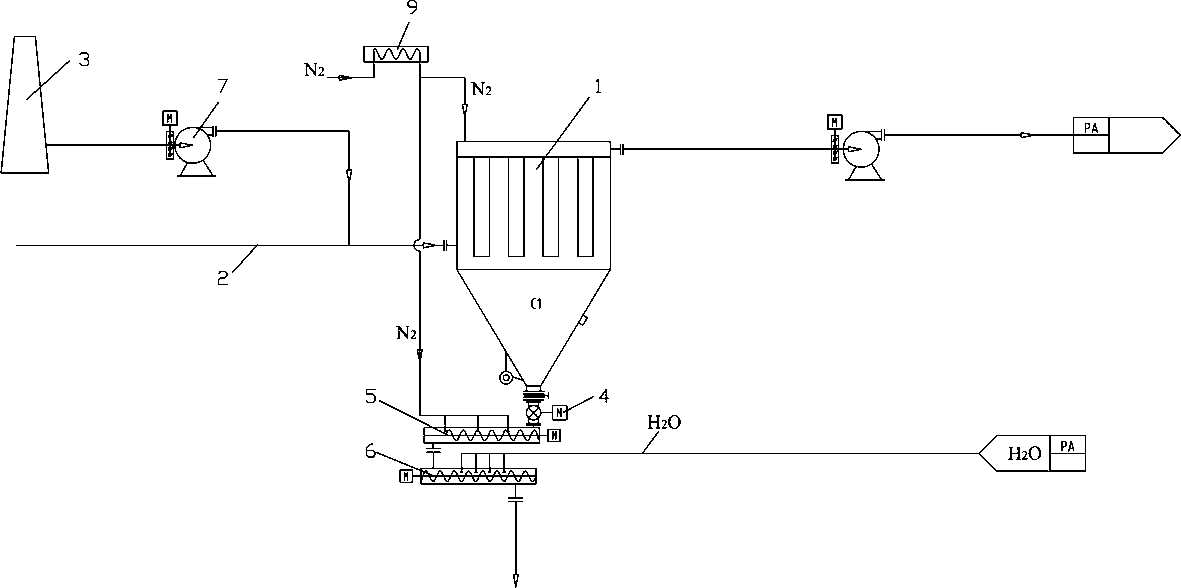

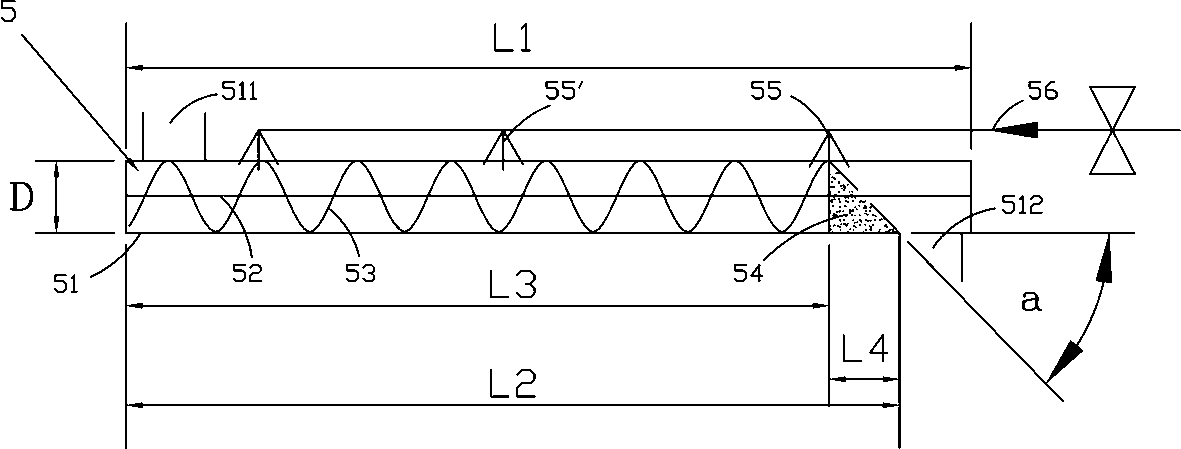

[0047] see figure 2 , image 3 , the dust removal system for coal humidity control of the present invention, it comprises, bag filter 1, its inlet pipeline is connected respectively drier outlet flue 2 and the flue of coke oven 3 and circulation fan 7; At the outlet of the ash bin of the bag filter 1; the ash discharge screw 5 is installed under the rotary ash discharge valve 4, and the ash discharge screw adopts an air-sealed structure; the humidifying mixer 6 is installed at the outlet of the ash discharge screw 5.

[0048] The bag filter 1 adopts heating nitrogen N 2 As the soot cleaning and backflushing medium, nitrogen is heated through the heat exchanger 9 for heat exchange.

[0049] The gas seal of the ash discharge screw 5 adopts nitrogen gas seal, and is connected to the above-mentioned heat exchanger 9 through the pipeline to exchange heat and heat the nitrogen pipeline.

[0050]The flue gas at the outlet of the dryer is mixed with the high-temperature flue gas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com