Method for upgrading and desulfurizing high-sulfur fat coal

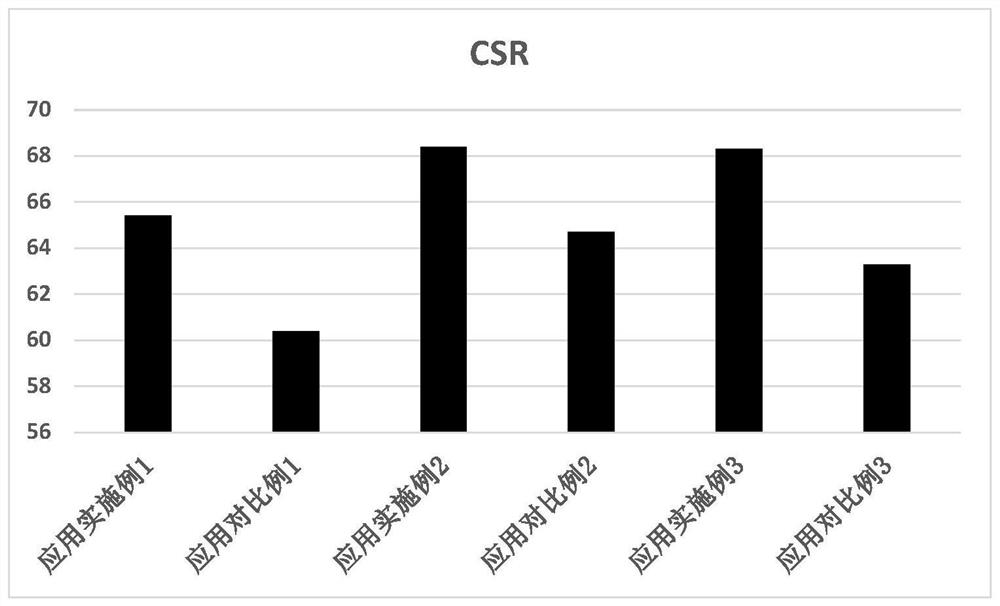

A fat coal, high-sulfur technology, applied in the field of coking, can solve the problems affecting the quality of pure iron in blast furnace ironmaking, increase the sulfur content of coke, etc., and achieve the effect of excellent cohesive index and thermal strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

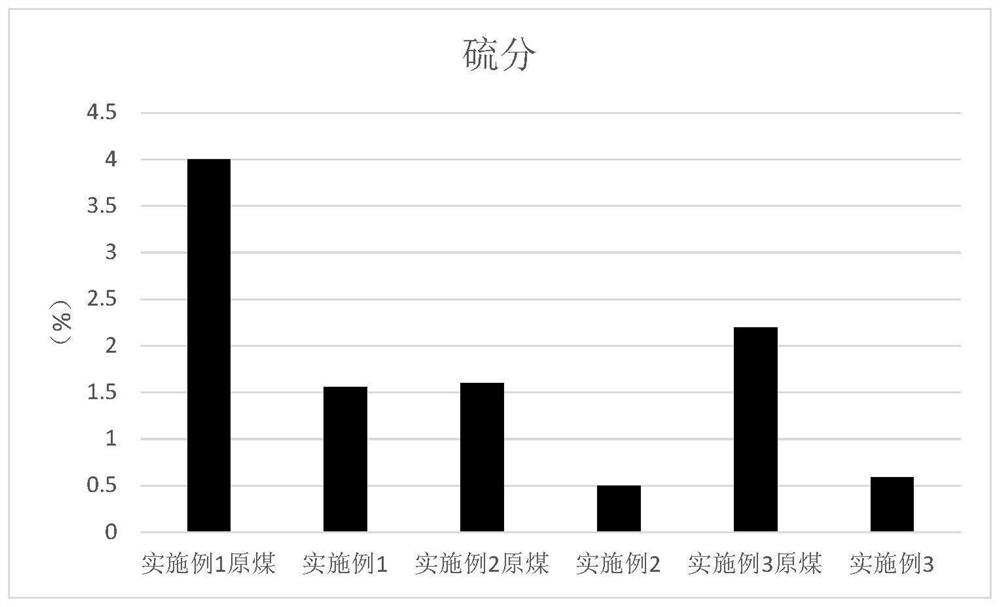

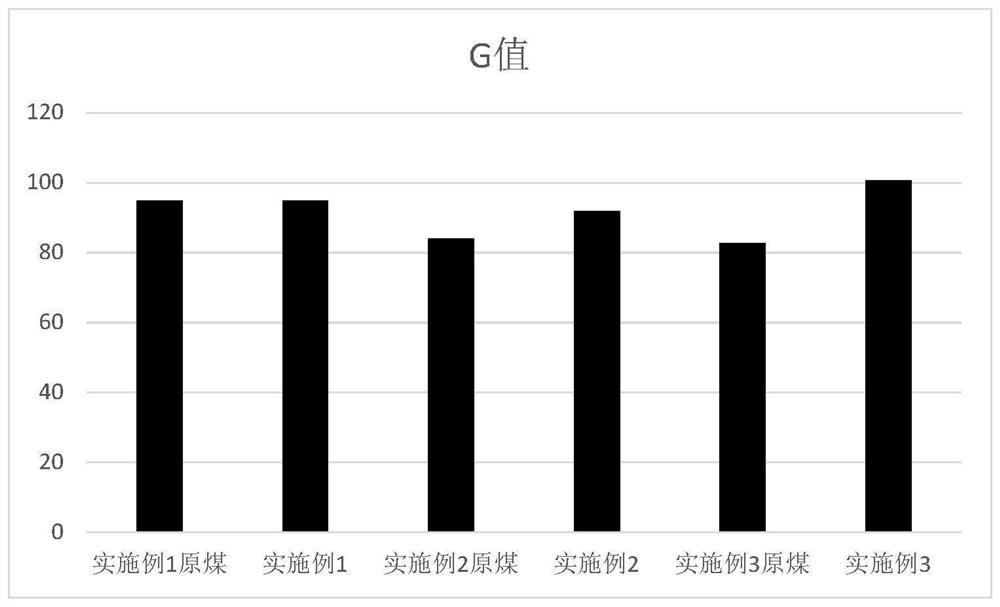

[0059] Take 5kg of Dongpang high-sulfur coal (sulfur content: 3.95%), 0.1kg of titanium dioxide, 0.05kg of nickel fluoroborate and 10L of citric acid aqueous solution (0.2mol / L) to form a slurry, stir and heat to 150°C under nitrogen atmosphere to react 2h; After the material is cooled to room temperature, the solvent is separated, the solid material is washed with deionized water, and then dried in a drying box at 110°C for 8h; 1kg of solid material is coked with 25L to produce rectified and cut washing oil (230-260°C Distillation section) mixed under nitrogen atmosphere, pressurized at 2Mpa, stirred and heated to 350°C for 1 hour; use heat preservation filter to separate liquid material and residue at 150°C; use flash tank to recover solvent and obtain 4.2kg of desulfurized coal.

Embodiment 2

[0061] Take 5kg of high-sulfur coal from Huai Mine (sulfur content: 1.6%), 0.1kg of titanium dioxide, 0.05kg of nickel fluoroborate and 10L of citric acid aqueous solution (0.2mol / L) to form a slurry, stir and heat to 150°C under nitrogen atmosphere to react 2h; After the material is cooled to room temperature, the solvent is separated, the solid material is washed with deionized water, and then dried in a drying box at 110°C for 8h; 1kg of solid material is coked with 25L to produce rectified and cut washing oil (230-260°C Distillation section) mixed under nitrogen atmosphere, pressurized at 2Mpa, stirred and heated to 350°C for 1 hour; use a heat preservation filter to separate the liquid material and residue at 150°C; use a flash tank to recover the solvent and obtain 4.25kg of desulfurized coal.

Embodiment 3

[0063] Take 5kg of Dongpang high-sulfur coal (sulfur content: 2.2%), 0.1kg of titanium dioxide, 0.05kg of nickel fluoroborate and 10L of citric acid aqueous solution (0.2mol / L) to form a slurry, stir and heat to 150°C under nitrogen atmosphere to react 2h; After the material is cooled to room temperature, the solvent is separated, the solid material is washed with deionized water, and then dried in a drying box at 110°C for 8h; 1kg of solid material is coked with 25L to produce rectified and cut washing oil (230-260°C Distillation section) mixed under nitrogen atmosphere, pressurized at 2Mpa, stirred and heated to 350°C for 1h; use a heat preservation filter to separate liquid materials and residues at 150°C; use a flash tank to recover the solvent and obtain 4.1kg of desulfurized coal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com