Briquette containing composite binder and burning synergistic agent and preparation method thereof

The technology of a synergist and a binder is applied in the field of briquette containing a composite binder and a combustion synergist and its preparation, and achieves the effects of low production cost, environmental protection and enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

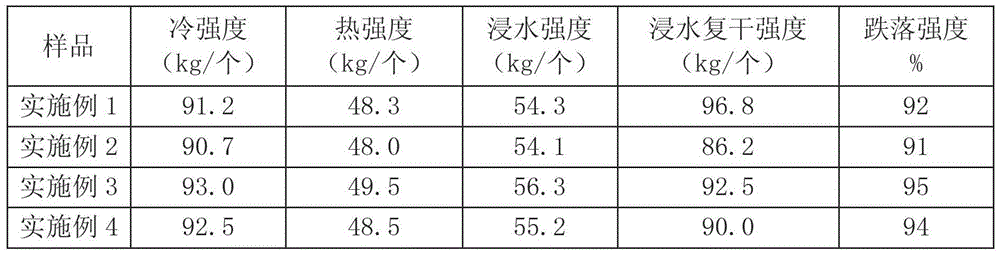

Examples

Embodiment 1

[0025] The preparation method of briquette containing composite binder and combustion synergist comprises the following steps:

[0026] 1. Weigh respectively according to the weight percentage of raw material components: bituminous coal powder 95kg, pregelatinized starch 5.5kg, kaolin 7.5kg, polyvinyl alcohol 1kg, potassium permanganate 0.05kg, sodium chloride 0.90kg, sodium carbonate 0.05kg kg;

[0027] 2. Add 13.2kg of water into the reactor, add polyvinyl alcohol, heat to 95°C, stir to dissolve completely, then add potassium permanganate, sodium chloride, and sodium carbonate respectively, stir to dissolve completely, and obtain a mixed solution;

[0028] 3. Mix the pregelatinized starch and kaolin evenly to obtain a mixture;

[0029] 4. Add the mixed solution and the mixture into the bituminous coal powder, stir and mix evenly, cold press molding, the molding pressure is 300 kg, and let it dry naturally.

Embodiment 2

[0031] The preparation method of briquette containing composite binder and combustion synergist comprises the following steps:

[0032] 1. Weigh respectively according to the weight percentage of raw material components: lignite powder 85kg, pregelatinized starch 1.5kg, refractory mud 2.9kg, polyvinyl alcohol 0.3kg, potassium permanganate 0.015kg, sodium chloride 0.27kg, sodium carbonate 0.015kg;

[0033] 2. Add 7.2kg of water into the reactor, add polyvinyl alcohol, heat to 80°C, stir to dissolve completely, then add potassium permanganate, sodium chloride, and sodium carbonate respectively, stir to dissolve completely, and obtain a mixed solution;

[0034] 3. Mix pregelatinized starch and refractory mud evenly to obtain a mixture;

[0035] 4. Add the mixed solution and the mixture into the lignite powder, stir and mix evenly, cold-press molding with a molding pressure of 200kg, and dry at 100°C to obtain the product.

Embodiment 3

[0037] The preparation method of briquette containing composite binder and combustion synergist comprises the following steps:

[0038] 1. Weigh respectively according to the weight percentage of raw material components: 90kg of anthracite powder, 3kg of pregelatinized starch, 2kg of kaolin, 2kg of bentonite, 0.6kg of polyvinyl alcohol, 0.03kg of potassium permanganate, 0.5kg of sodium chloride, sodium carbonate 0.03kg;

[0039] 2. Add 10kg of water into the reactor, add polyvinyl alcohol, heat to 90°C, stir to dissolve completely, then add potassium permanganate, sodium chloride, and sodium carbonate respectively, stir to dissolve completely, and obtain a mixed solution;

[0040] 3. Mix pregelatinized starch, kaolin and bentonite evenly to obtain a mixture;

[0041] 4. Add the mixed solution and the mixture into anthracite powder, stir and mix evenly, cold-press molding with a molding pressure of 300kg, and dry at 90°C to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com