Cement-free iron runner castable

An iron ditch castable, cement-free technology, applied in the field of refractory materials, can solve the problems such as jeopardizing the high temperature strength of the iron ditch castable and slag iron corrosion resistance, difficult to meet the requirements of rapid construction of the iron ditch, and the concentration of hydrate water loss temperature. , to achieve the effect of excellent resistance to slag intrusion, good mechanical strength and low water addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

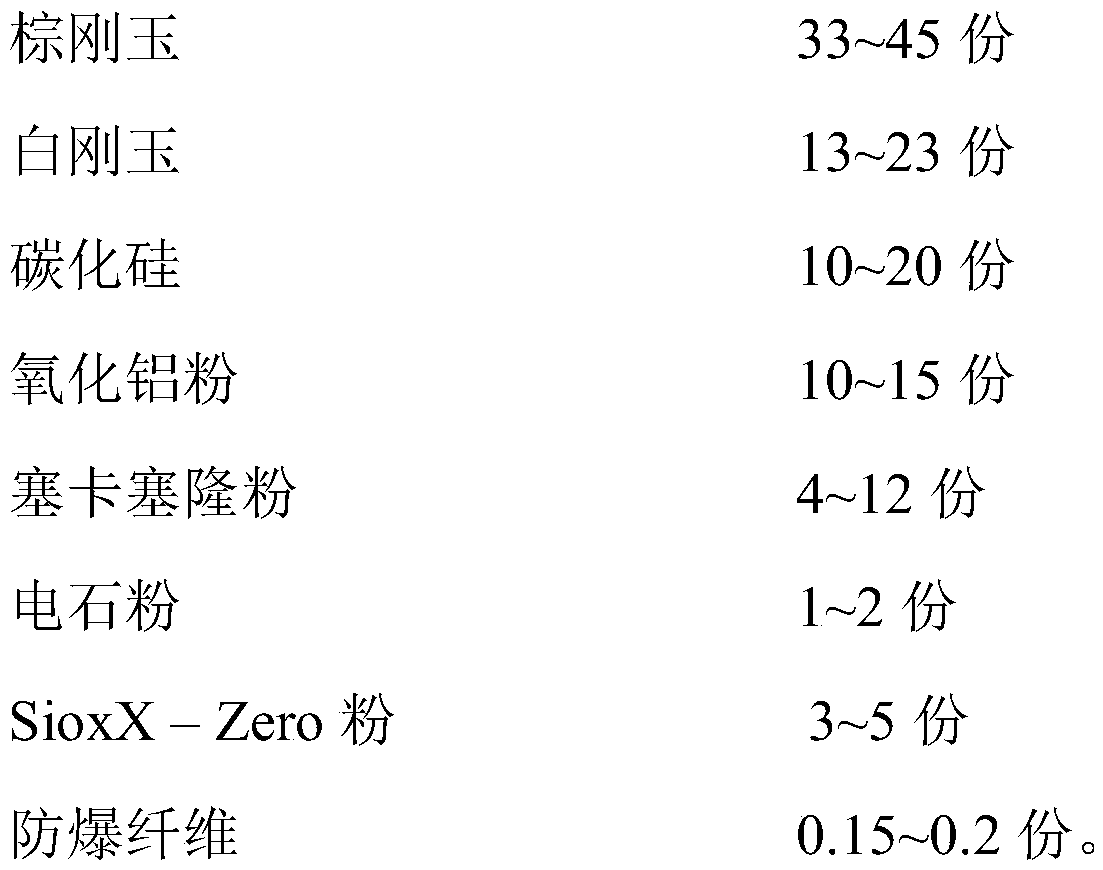

[0022] A cementless iron ditch castable, comprising the following components and parts by weight:

[0023]

[0024]

[0025] Wherein, the mass percentage of SiC in the silicon carbide is not less than 95%; 3 N 4 The mass percentage content of SiO is not less than 70%, the mass percentage content of SiC is not less than 10%, and the mass percentage content of SiC is not less than 10%; the SiO in the SioxX-Zero powder 2 The mass percentage content is 55-70%, A1 2 o 3 The mass percentage content is 25~40%.

Embodiment 2

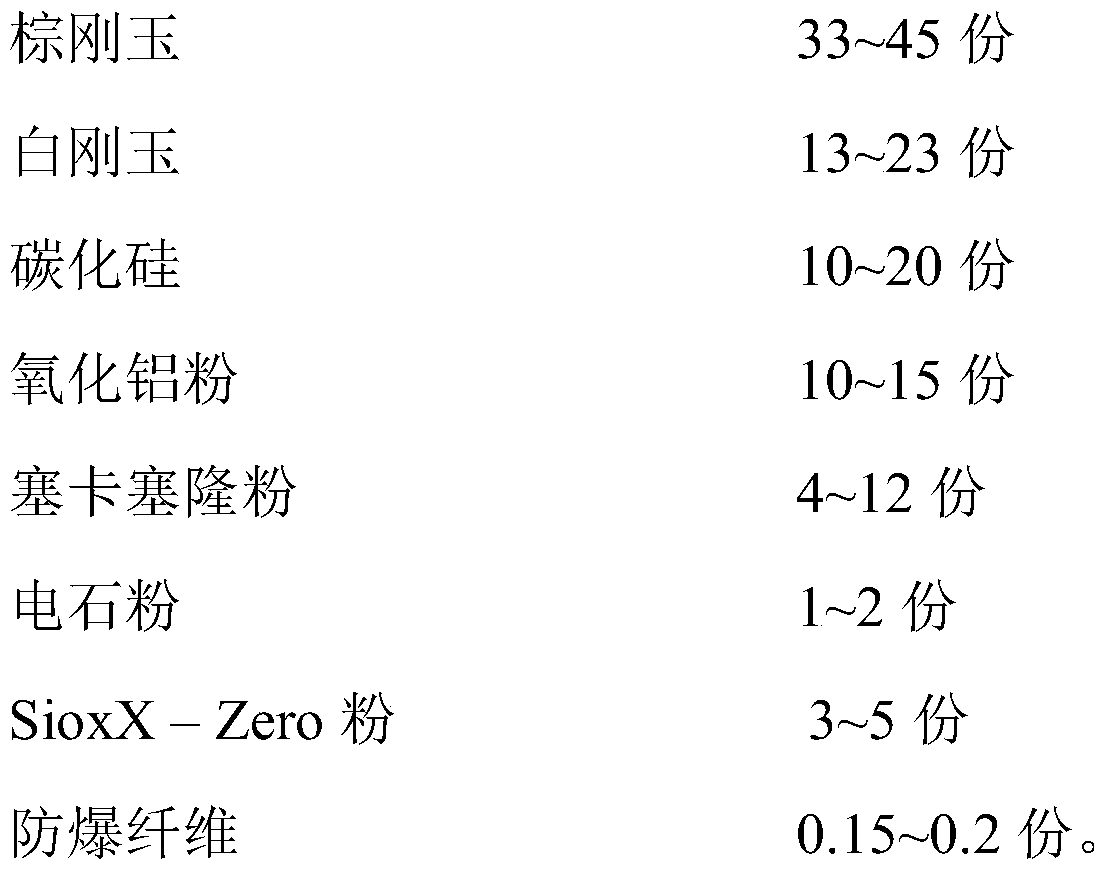

[0027] A cementless iron ditch castable, comprising the following components and parts by weight:

[0028]

[0029] Wherein, the mass percentage of SiC in the silicon carbide is not less than 95%; 3 N 4 The mass percentage content of SiO is not less than 70%, the mass percentage content of SiC is not less than 10%, and the mass percentage content of SiC is not less than 10%; the SiO in the SioxX-Zero powder 2 The mass percentage content is 55-70%, A1 2 o 3 The mass percentage content is 25~40%.

Embodiment 3

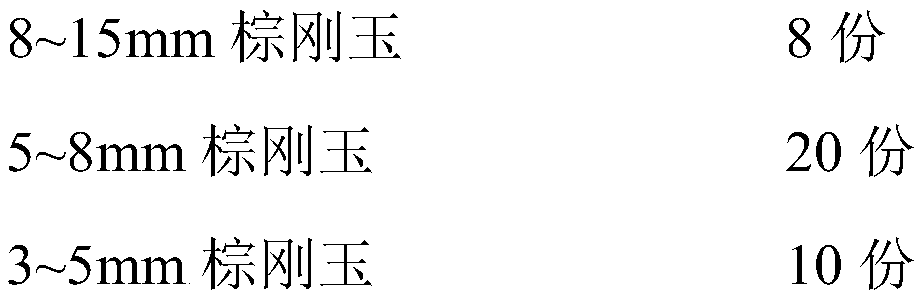

[0031] A cementless iron ditch castable, comprising the following components and parts by weight:

[0032]

[0033] Wherein, the mass percentage of SiC in the silicon carbide is not less than 95%; 3 N 4 The mass percentage content of SiO is not less than 70%, the mass percentage content of SiC is not less than 10%, and the mass percentage content of SiC is not less than 10%; the SiO in the SioxX-Zero powder 2 The mass percentage content is 55-70%, A1 2 o 3 The mass percentage content is 25~40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com