Method for making aluminum-magnesium carbon refectory brick from regenerated magnesium carbon bricks and aluminum-magnesium carbon bricks

A technology of aluminum-magnesium-carbon refractory bricks and magnesia-carbon bricks is applied in the field of refractory materials, which can solve the problems of poor stability and low life expectancy, and achieve the effects of strong impact resistance, high mechanical strength and reduction of pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

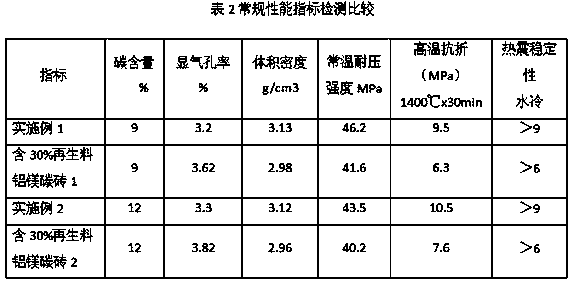

Embodiment 1

[0033] The method for manufacturing aluminum-magnesium-carbon refractory bricks using recycled magnesia-carbon bricks and aluminum-magnesium-carbon bricks includes the following steps:

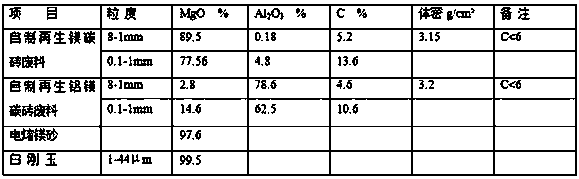

[0034] Self-made recycled magnesia-carbon brick waste, particle size of 10%-30% of 8-1mm, 5%-15% of particle size of 0.1-1mm; self-made recycled aluminum-magnesia carbon brick waste, particle size of 15-40% of 8-1mm, particle size of 5%-15% of 0.1-1mm; fused magnesia, particle size of 5%-10% of 0.1-1mm

[0035] The specific configuration is as follows:

[0036] Granularity of recycled magnesia carbon brick waste is 8-1mm 10%, 0.1-1mm 5%;

[0037] Granularity of recycled aluminum-magnesium-carbon brick scrap is 8-1mm 45%, 0.1-1mm 10%;

[0038] The particle size of fused magnesia is 0.1m-1m 5%, 1μm-74μm 5%;

[0039] White corundum powder 1-44μm 8%

[0040] Needle coke particle size 1.5%; graphite particle size 100 mesh 2%;

[0041] Asphalt powder 0.5%; Metal silicon powder 200 mesh 1%; Nano silicon carbide ...

Embodiment 2

[0053] Method for manufacturing aluminum-magnesium-carbon refractory bricks using recycled magnesia-carbon bricks and aluminum-magnesium-carbon bricks:

[0054] Self-made recycled magnesia-carbon brick waste, particle size of 10%-30% of 8-1mm, 5%-15% of particle size of 0.1-1mm; self-made recycled aluminum-magnesia carbon brick waste, particle size of 15-40% of 8-1mm, particle size of 5%-15% of 0.1-1mm; fused magnesia, particle size of 5%-10% of 0.1-1mm

[0055] Specific ratio:

[0056] Recycled magnesia carbon brick waste, particle size 8-1mm 10%, 0.1-1mm 3%;

[0057] Recycled aluminum-magnesium-carbon brick waste, particle size 8-1mm 42%, 0.1-1mm 5%;

[0058] The particle size of fused magnesia is 0.1m-1m 8%, 1μm-74μm 5%;

[0059] White corundum powder 1-44μm 10%

[0060] Needle coke particle size 2%; graphite particle size 100 mesh 4%;

[0061] Pitch powder 1.5%; Metal silicon powder 200 mesh 1%; Nano silicon carbide 5%;

[0062] Metal aluminum powder 180 mesh 1%; a-alumina powder 1.5%;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com