Fault prediction method based on machine learning

A fault prediction and machine learning technology, applied in machine learning, prediction, instruments, etc., can solve problems such as excess, waste of resources, excess maintenance, etc., to reduce costs, reduce maintenance costs, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

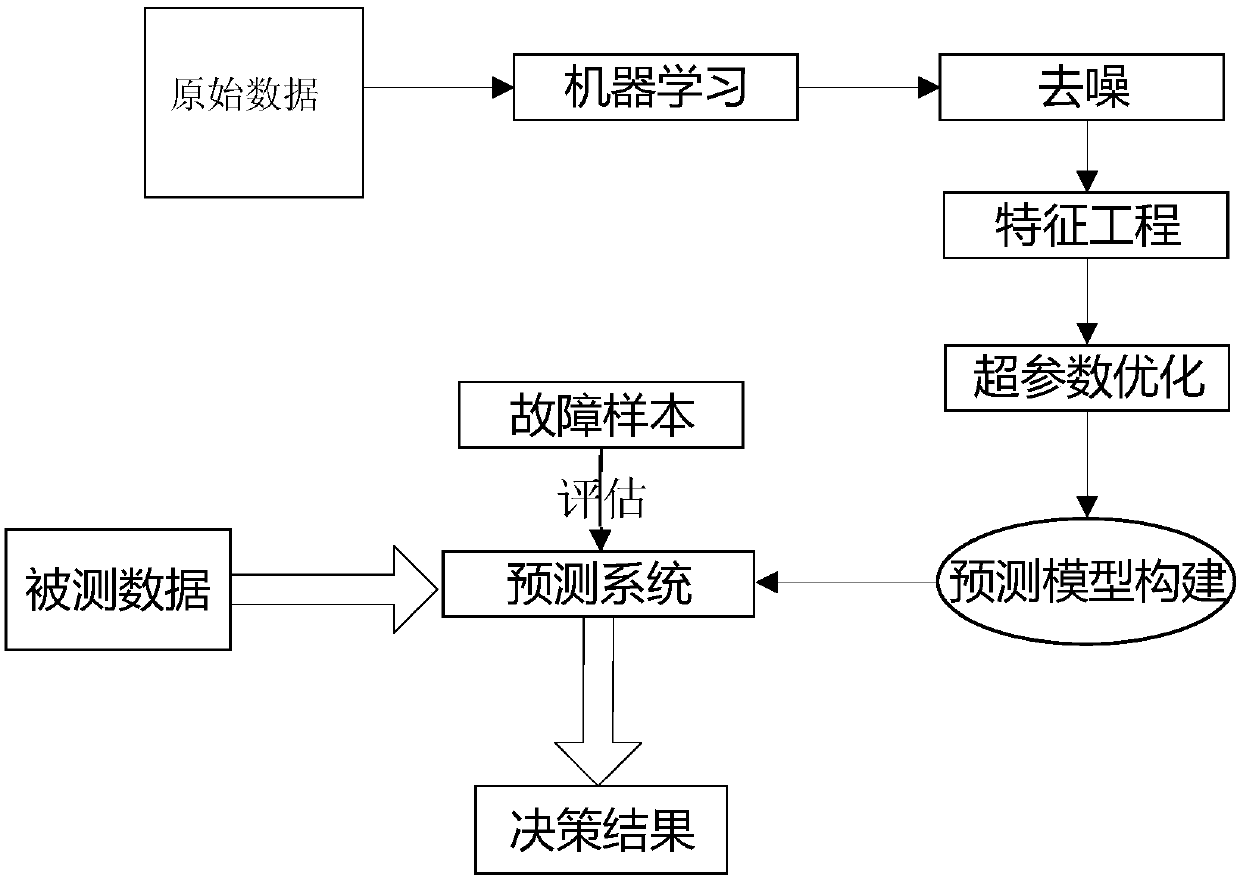

Image

Examples

Embodiment Construction

[0026] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

[0027] Data is the foundation of machine learning to solve problems. If the data is not selected correctly, the problem cannot be solved. First, the data is divided into two parts, one part is mainly the basic technical parameters of the equipment, operating index data, and known data of past failures. The specific parameters involve equipment temperature, heat, rotation speed, displacement, process parameters and vibration. The other part is the time series data of the above parameters of equipment operation. This type of data is to install sensors in the required prediction object (such as equipment or system) to collect real-time data of the operation of the prediction object, and perform the characteristic analysis of the above two parts of da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com