Hydropower station remote centralized control and quick service platform

A rapid service and hydropower station technology, applied in the direction of electrical program control, program control, and comprehensive factory control, can solve the problems of centralized control management of limited parts of hydropower stations, poor operating conditions of hydropower stations, lack of effective integration of industry resources, etc., to achieve convenient purchase Effect of selection, shortening time of purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] Below with reference to accompanying drawing and in conjunction with embodiment, describe the present invention in detail:

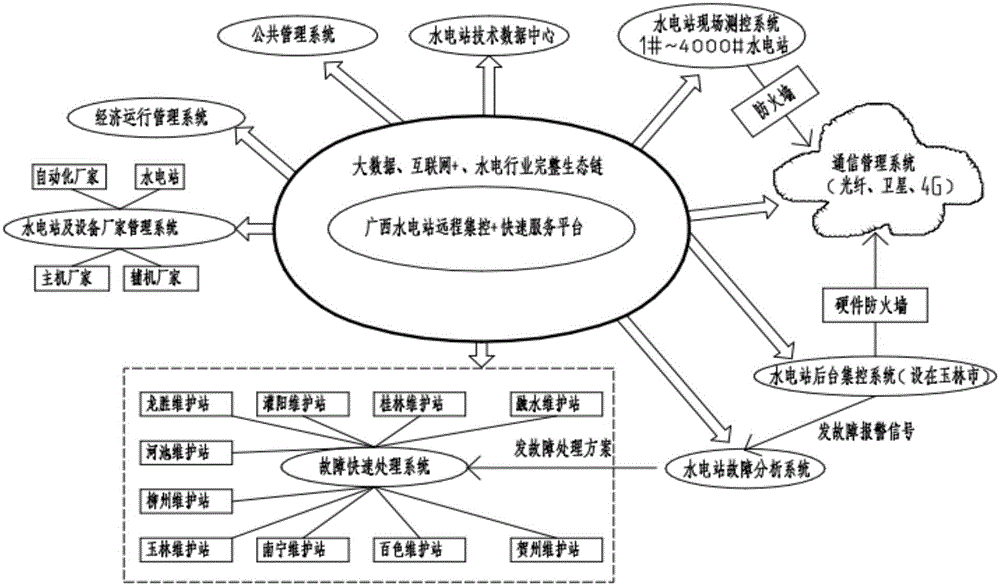

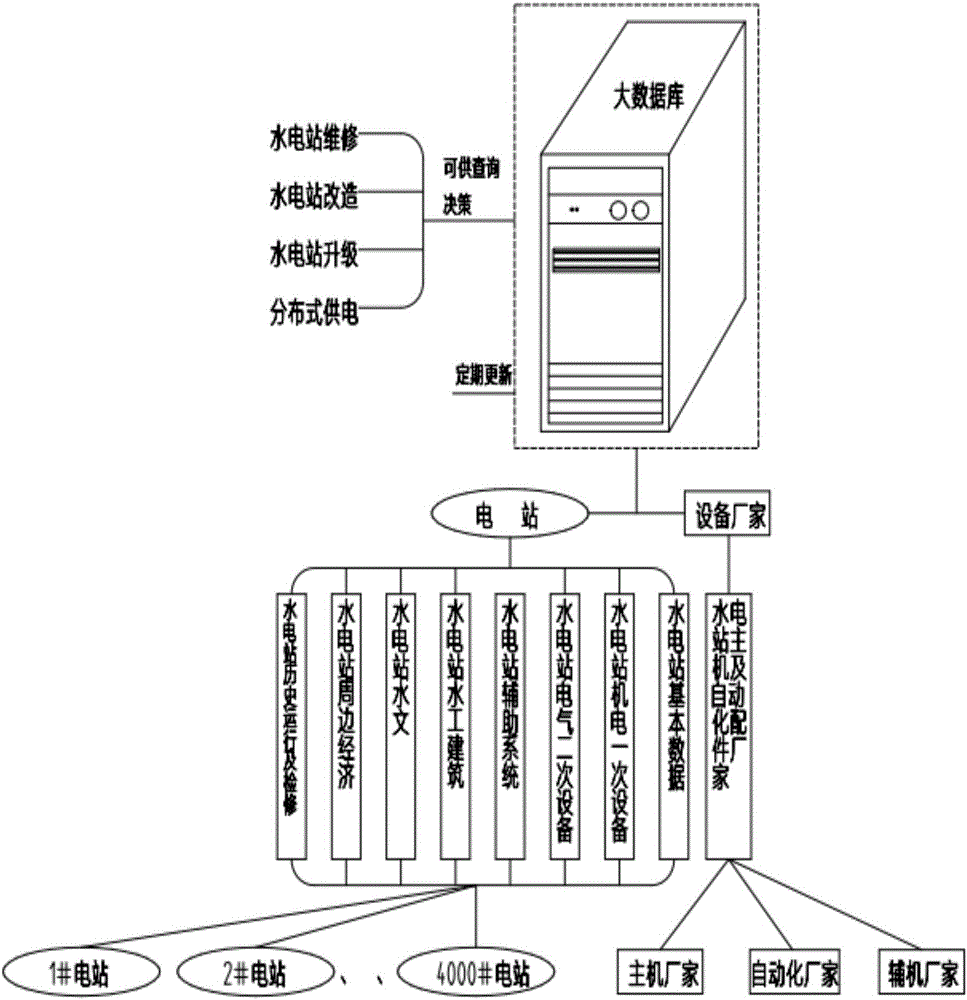

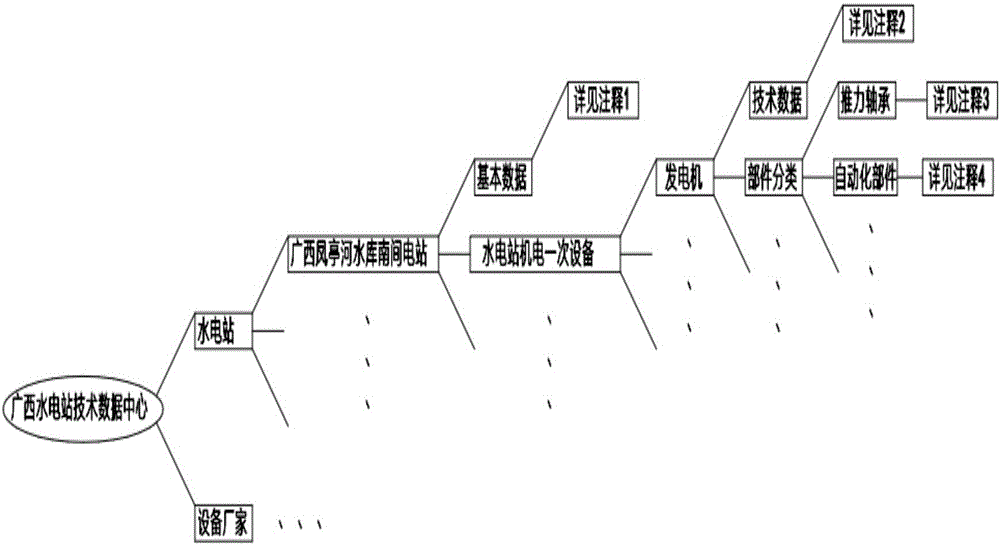

[0109] as attached figure 1 Shown is the remote centralized control + fast service platform system diagram of Guangxi hydropower stations. The platform includes 4,000 small and medium-sized hydropower stations in Guangxi and all main engine, auxiliary engine and automation equipment manufacturers in Guangxi. This platform is built on the basis of big data and cloud computing using the Internet+ model. It can realize the unmanned and less manned duty of small and medium hydropower stations in Guangxi, and integrate the design, production, sales, installation, maintenance, and operation of Guangxi's hydropower industry. Organic integration forms a complete ecological industry chain of the industry.

[0110] Guangxi hydropower station remote centralized control + fast service platform includes hydropower station technical data center, hydropower sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com