Complex product assembly process accurate repair method based on digital twinning and operation system thereof

A technology for assembly process and complex products, which is applied in the field of precise repairing methods and operating systems for complex product assembly processes, and can solve the problems of uncertainty in repairing plans, lack of effective guidance for assembly and adjustment methods at the assembly site, and insufficient fusion of virtual and real mapping. Avoid lack of guidance and achieve the effect of online accurate repair tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

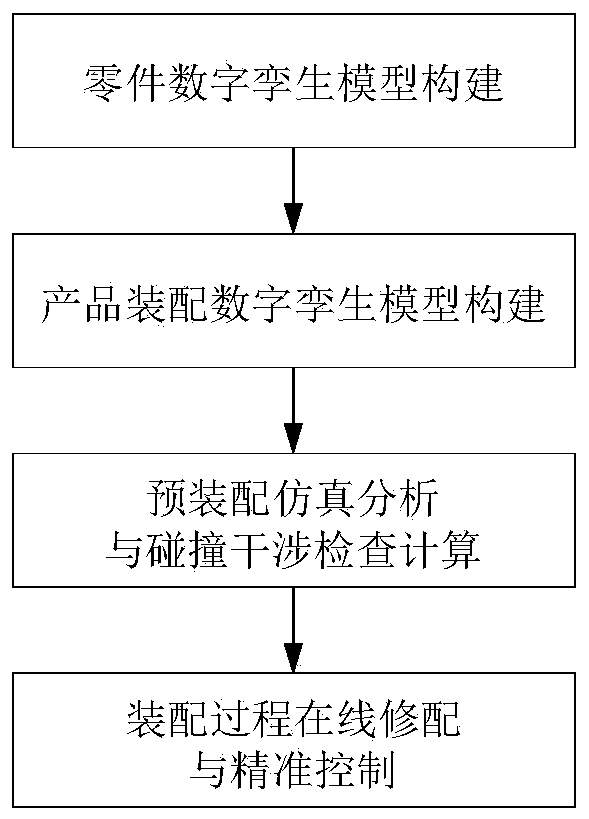

[0051] Such as Figure 1~5 As shown, this embodiment provides a digital twin-based precise repair method for complex product assembly process, including the following steps:

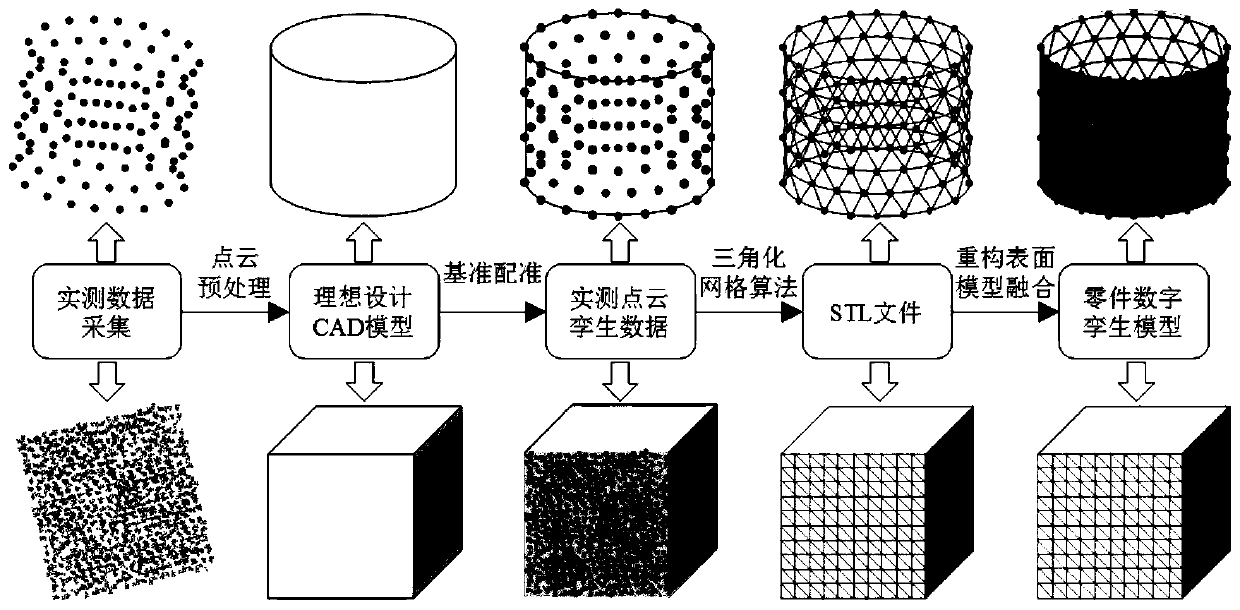

[0052] (1) Construction of digital twin model of parts

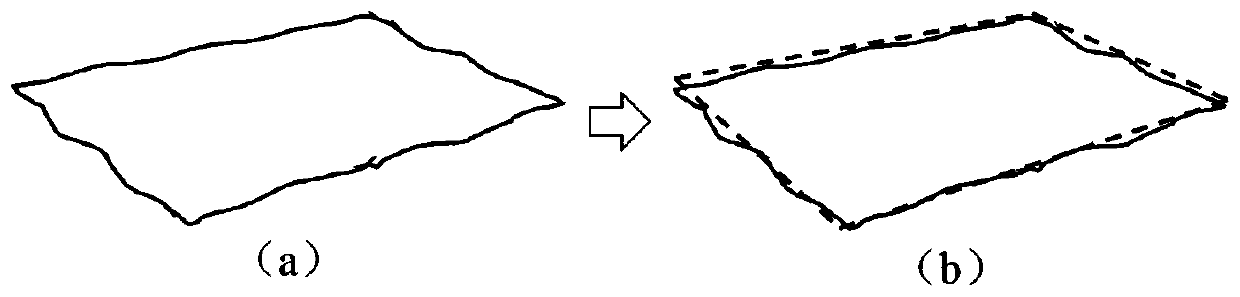

[0053] Obtain the part design CAD model and product assembly design CAD model from the computer-aided design system, and based on the key assembly process in the product assembly process, carry out feature identification and division on the assembly matching area of the parts, and analyze the actual parts on the physical assembly site The assembly matching surface is used to collect, process and express the measured data, and the part assembly matching surface with the measured twin data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com