Wide-band laser-induced hybrid cladding restoration and surface strengthening method for dies

A technology of laser induction and surface strengthening, which is applied in coating, metal material coating process, etc., can solve problems such as poor mold bonding force, difficult shape damage, and pollution of the repair environment, so as to eliminate pores and cracks and improve service life , The effect of shortening the repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

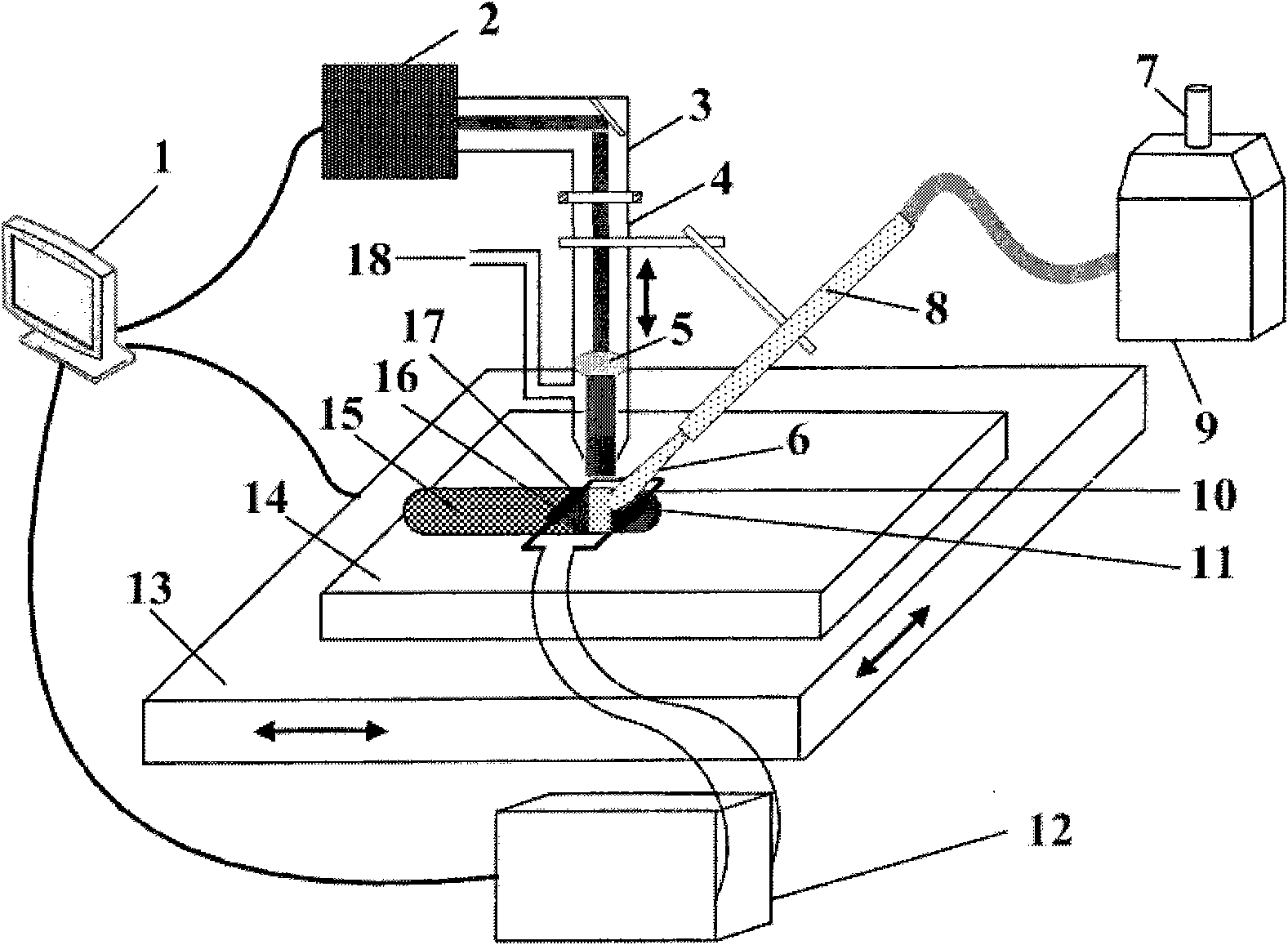

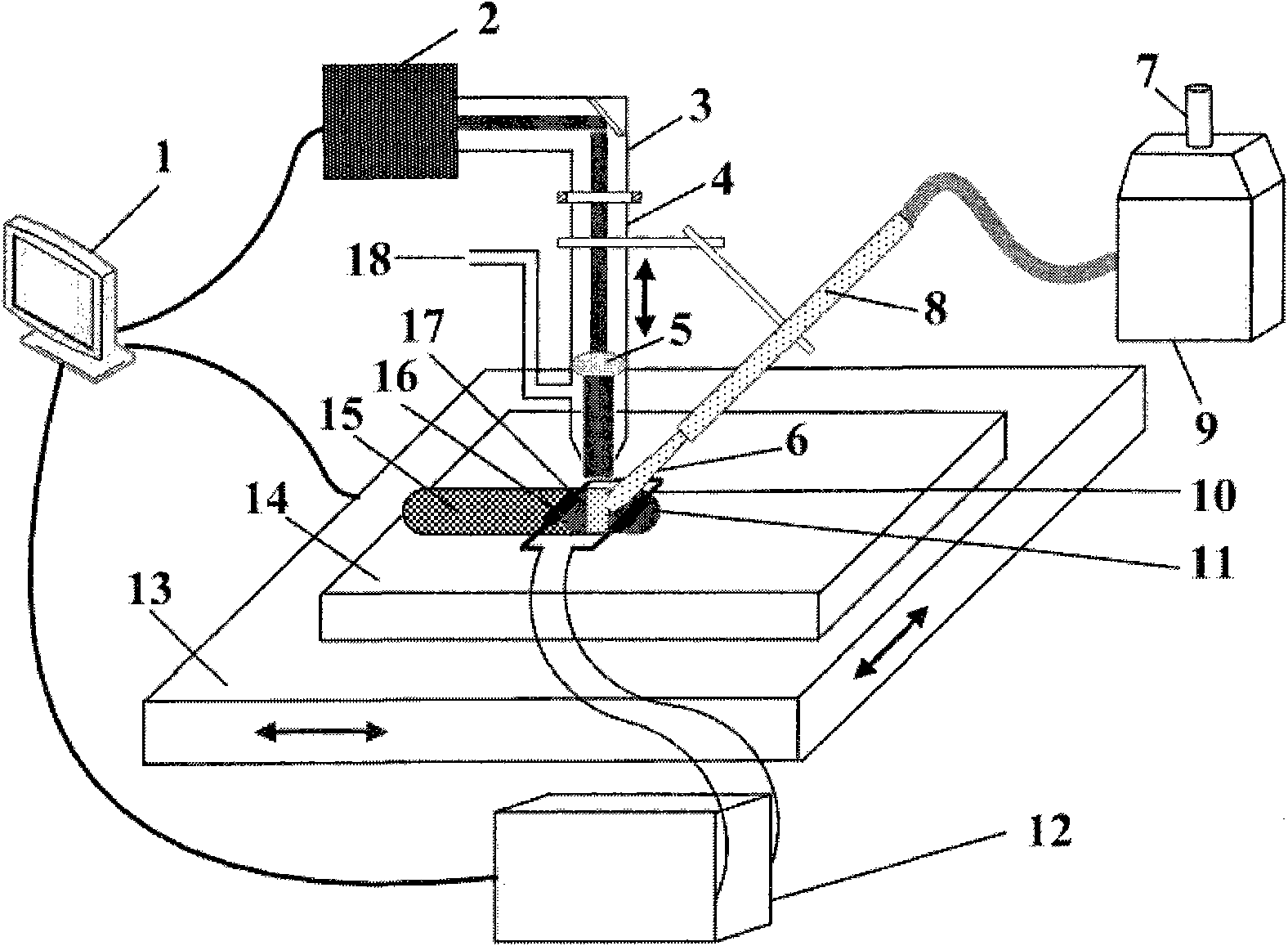

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

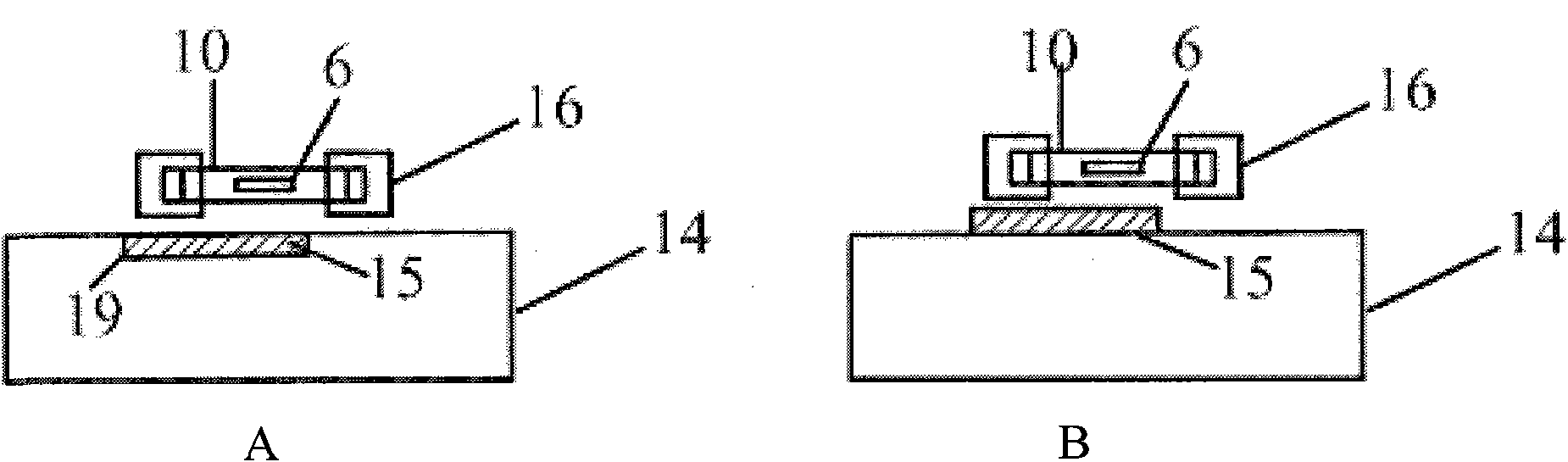

[0024] Such as figure 1 , figure 2 As shown, using broadband laser induction composite cladding repair and surface strengthening mold, the specific implementation process is as follows:

[0025] 1. Derusting, degreasing and acetone cleaning the part (19) of the mold to be processed.

[0026] 2. Put the special Ni-based alloy powder (8) into the loading hopper (7) of the automatic powder feeder (9), and connect the part of the mold to be processed (19) with the induction heating coil ( 10) The distance between them is adjusted to 8mm, the induction heating coil (10) is energized, and the power of the induction heating power supply (12) is adjusted by the computer (1), so that the part of the mold to be processed (19) is heated by the induction heating coil (10) Heating to 200-950° C., while using copper pipe (18) to blow Ar gas into the induction heating zone (11) a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com