High-strength and anti-stripping type homogenous composite castable and preparation method

A castable and anti-stripping technology, which is applied in the field of refractory castables, can solve the problems of poor resistance to mechanical stress and thermal stress, small linear change, and low high-temperature strength, and achieve low porosity, uniform structure, and improved thermal strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

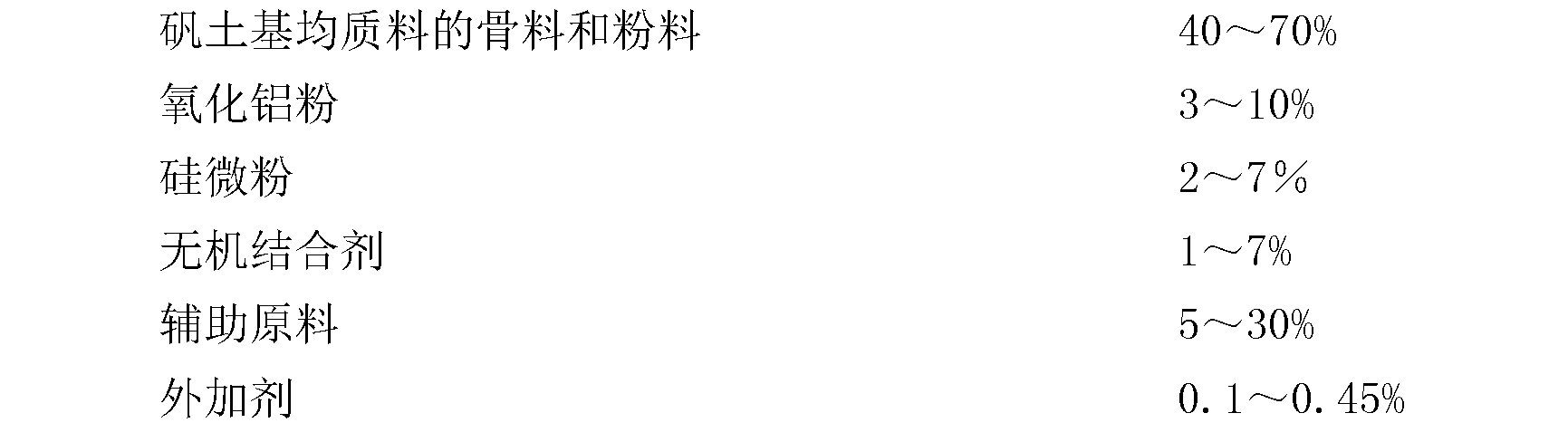

Method used

Image

Examples

Embodiment 1

[0019] The high-strength anti-stripping homogeneous composite castable is prepared according to the following ratio:

[0020]

[0021] Note: * contains one or more of ≥8mm, 5~8 mm, 3~5 mm, 1~3 mm, 0~1 mm, and 180 mesh.

Embodiment 2

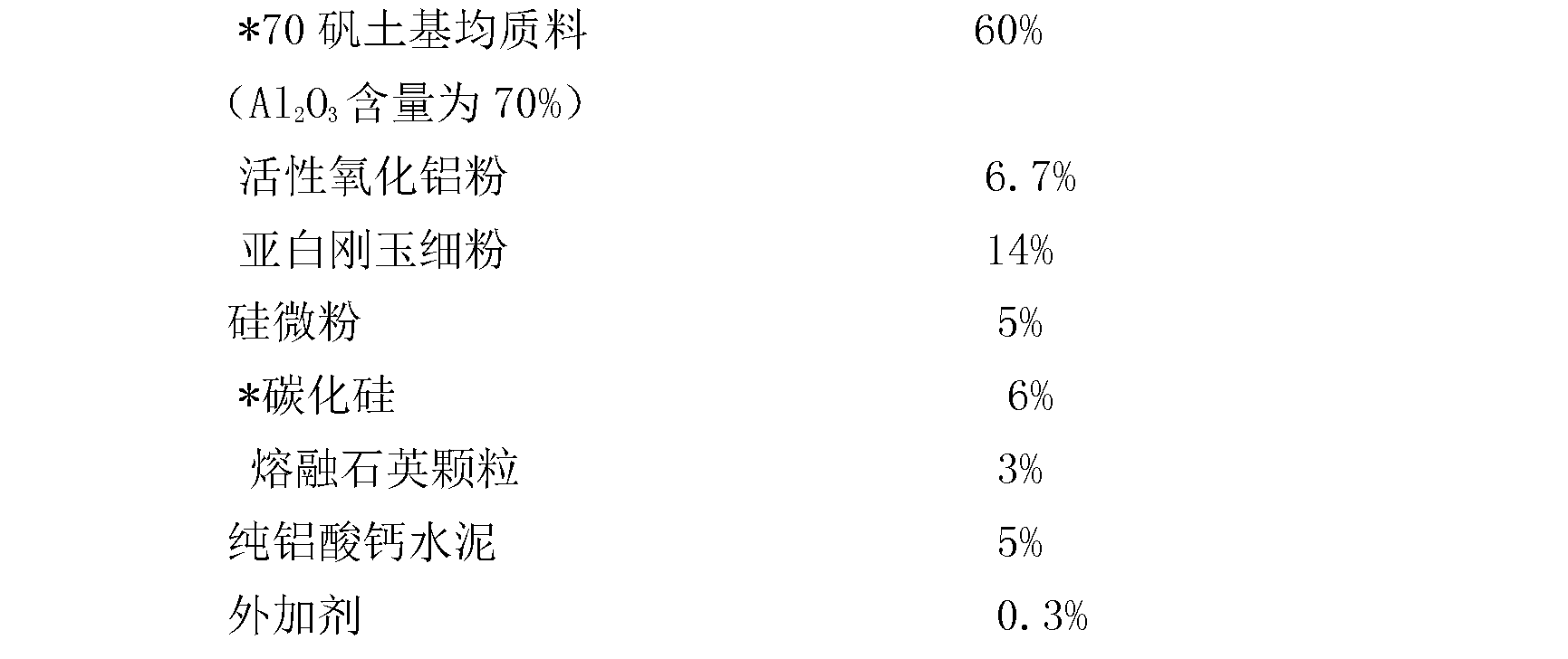

[0023] The new high-strength anti-stripping homogeneous composite castable is prepared according to the following ratio:

[0024]

[0025] Note: * contains one or more of ≥8mm, 5-8 mm, 3-5 mm, 1-3 mm, 0-1 mm, and 180 mesh.

Embodiment 3

[0027] The new high-strength anti-stripping homogeneous composite castable is prepared according to the following ratio:

[0028]

[0029]

[0030] Note: * contains one or more of ≥8mm, 5-8 mm, 3-5 mm, 1-3 mm, 0-1 mm, and 180 mesh.

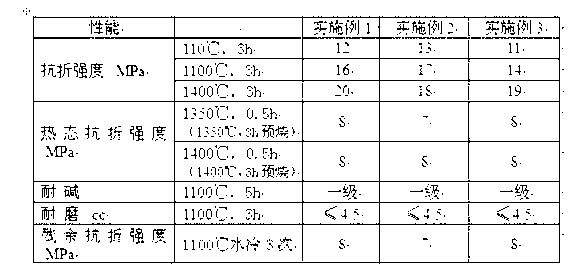

[0031] The properties of the example of the high-strength anti-stripping homogeneous composite castable prepared by using the alumina-based homogeneous material in the present invention are shown in the attached table:

[0032] Schedule:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com