Double-slit flap with flap body fixedly connected with additional wing

A technology of double-slot flaps and flaps, which is applied in the field of aircraft wings, can solve the problems of increased structural weight, increased cruise flight resistance, and small ΔCLmax, so as to reduce structural weight and aerodynamic drag, increase the maximum lift coefficient, and improve The effect of aircraft performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

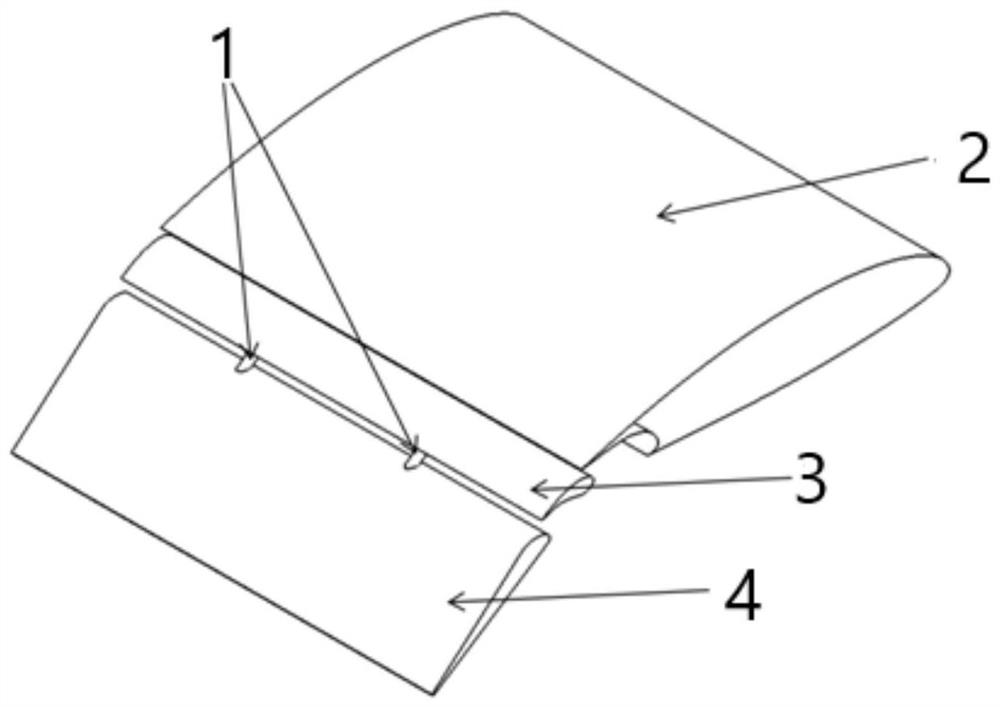

[0023] Such as figure 2 and 3 As shown, a double-slotted flap in which the flap is fixedly connected to the additional wing includes an additional wing 3 and a flap 4, and the additional wing 3 and the flap 4 are fixedly connected by a connecting rod 1, and the fixedly connected additional wing 3 and the flap 4 as a whole are retractable under the action of a set of driving connection mechanism; when the double-slotted flap is in the lowered state, between the main wing 2 and the additional wing 3, and between the additional wing 3 and the flap 4 are respectively There is a slot that produces the high-lift effect of a double-slotted flap.

[0024] The additional wing 3 and the flap 4 are fixedly connected by two connecting rods 1 .

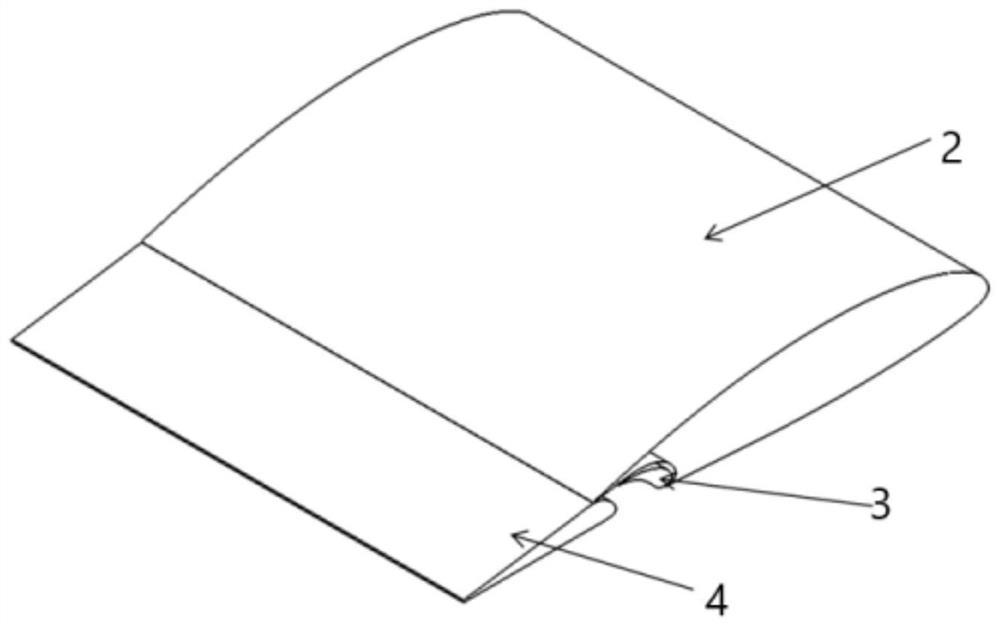

[0025] Such as Figure 4 and 5 As shown, when the double-slotted flap is in retracted state, for the airfoil whose chord ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com