Formula and technique for manufacturing geophysical prospecting bit by powder sintering

A drill bit and powder technology, which is applied in the formulation and process of powder sintering to manufacture geophysical drill bits, can solve the problems of poor applicability, high cost, and difficulty in drilling into holes in rock formations, and achieve improved wear resistance and impact resistance, improved service life, and improved The effect of penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

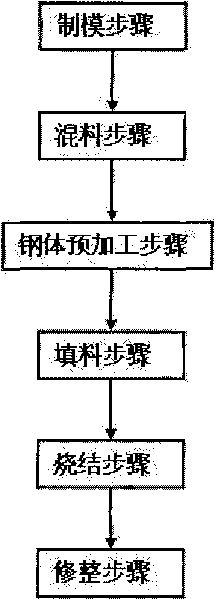

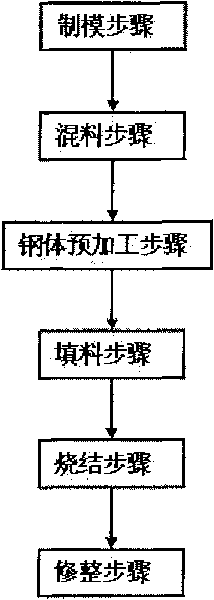

[0025] Such as figure 1 Shown, a kind of powder sintering of the present invention manufactures the prescription of geophysical drilling bit and the process comprises the following steps:

[0026] (1) Mold making steps: according to the mold processing drawings, use high-purity graphite electrodes to process a complete set of molds for the bottom mold, middle mold and upper mold on a lathe, and use plexiglass plates to make nozzle templates and chip removal block templates. The graphite mud Press into the prepared chip removal block template, press the prepared nozzle core mixture into the nozzle template, and take it out after forming. Use a dividing head with a diameter of 150mm and a magnetic scribing plate to mark on the bottom mold and position the hard core. For the alloy hole, chip removal block and nozzle core, use a twist drill to drill the carbide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com