Dispensing structure and process for improving reliability of LED lamp bead

A technology of LED lamp beads and reliability, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of affecting the life of LED devices, hindering commercial application, poor moisture resistance, etc., and achieves simple structure, reasonable setting, and increased reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

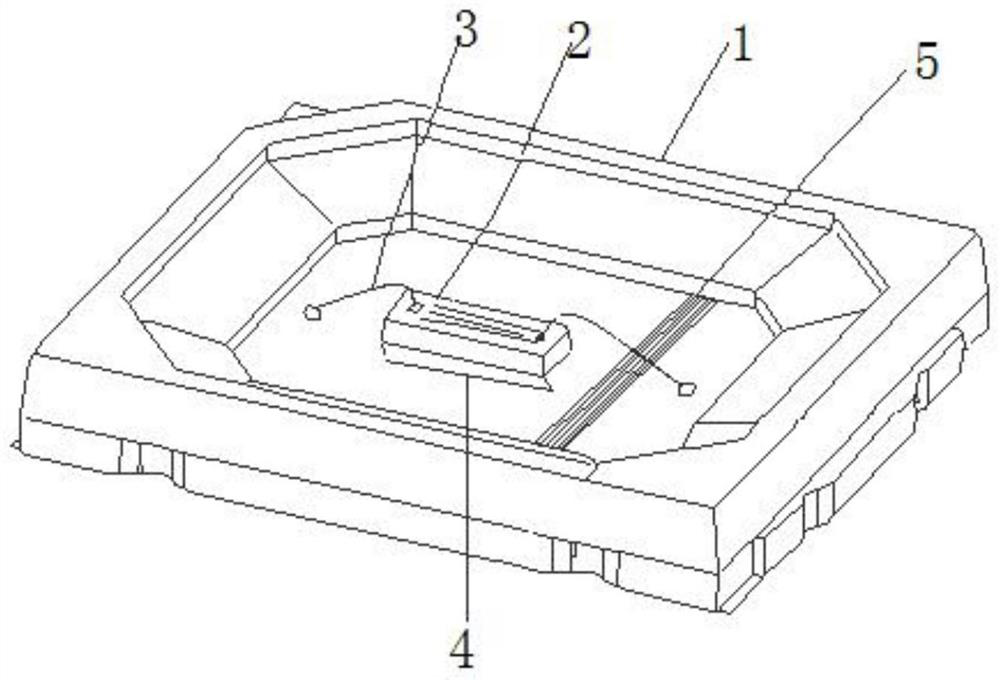

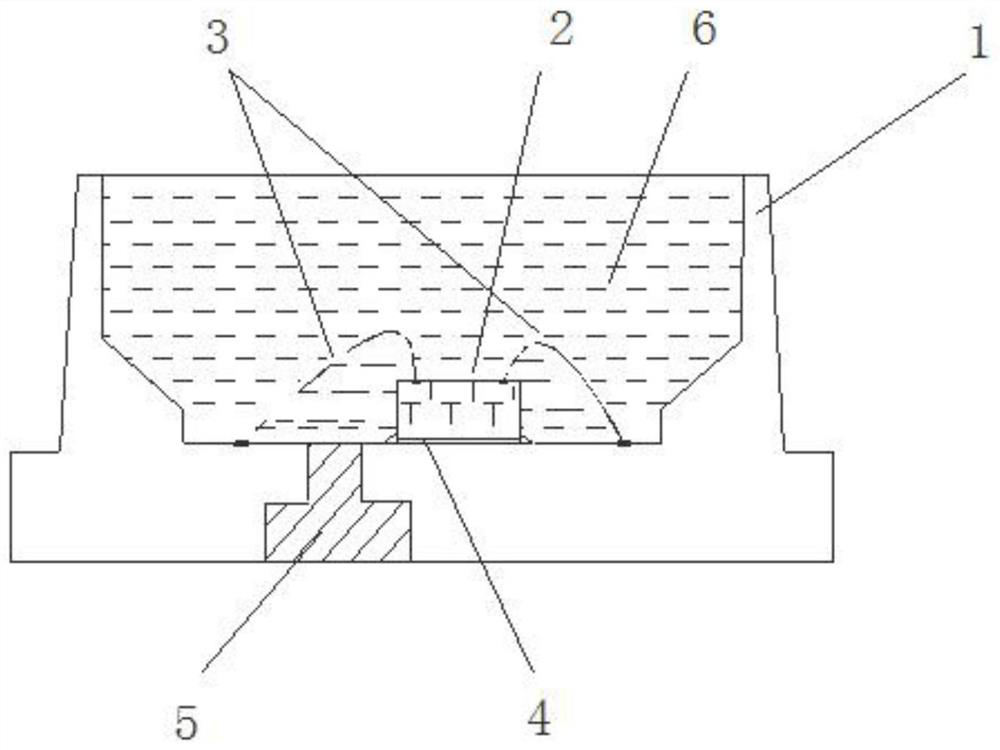

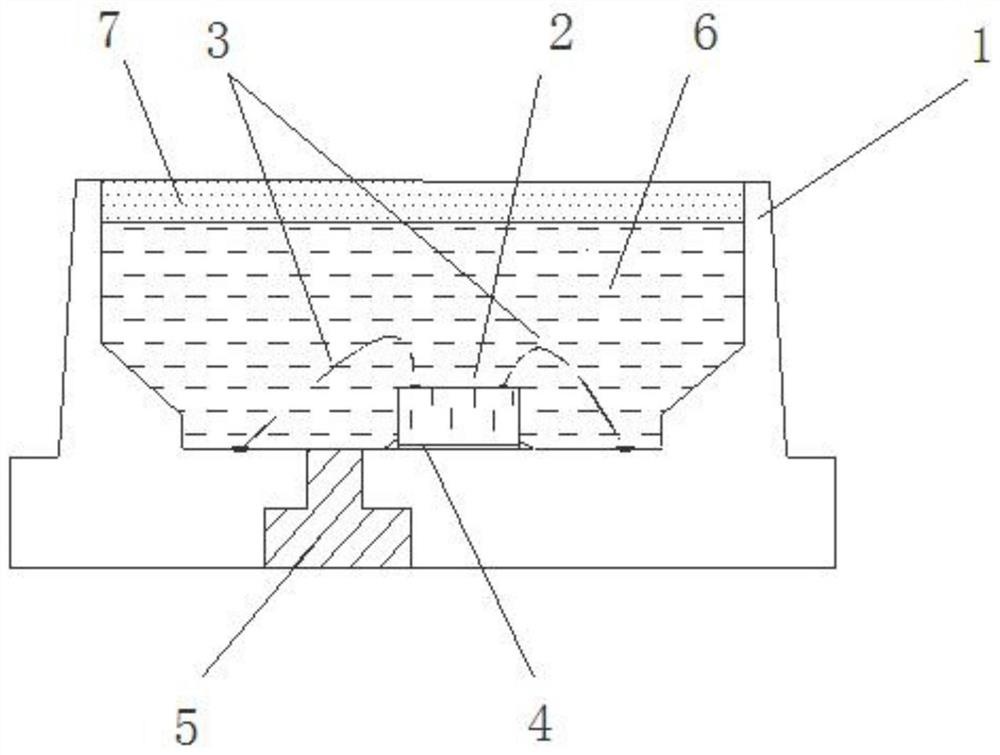

[0017] refer to Figure 3-4 , this specific embodiment adopts the following technical solutions: a glue dispensing structure to improve the reliability of LED lamp beads, including a bracket bowl cup 1, a chip 2, a bonding gold wire 3, a solid crystal glue 4, a white road 5, a fluorescent glue 6 and a white glue Glue 7, the inner bottom of the bracket bowl cup 1 is fixed with chip 2 through crystal-bonding glue 4; the positive and negative electrodes of the chip 2 are welded and connected to one end of the bonded gold wire 3; In the negative electrode area; the fluorescent glue 6 is filled in the bracket bowl, but it is not completely filled. After high temperature baking, the fluorescent glue 6 is not completely cured and is in a semi-solid state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com