Bonding alloy wire and preparation and application thereof

An alloy wire and alloy technology, applied in the field of bonding alloy wire and its preparation and application, can solve the problems of increasing the production and flow costs of bonded gold wire manufacturers, unstable wire arc performance, heavy raw material costs, etc., and achieve easy operation and welding, avoiding the phenomenon of sliding balls, and the effect of low frequency of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

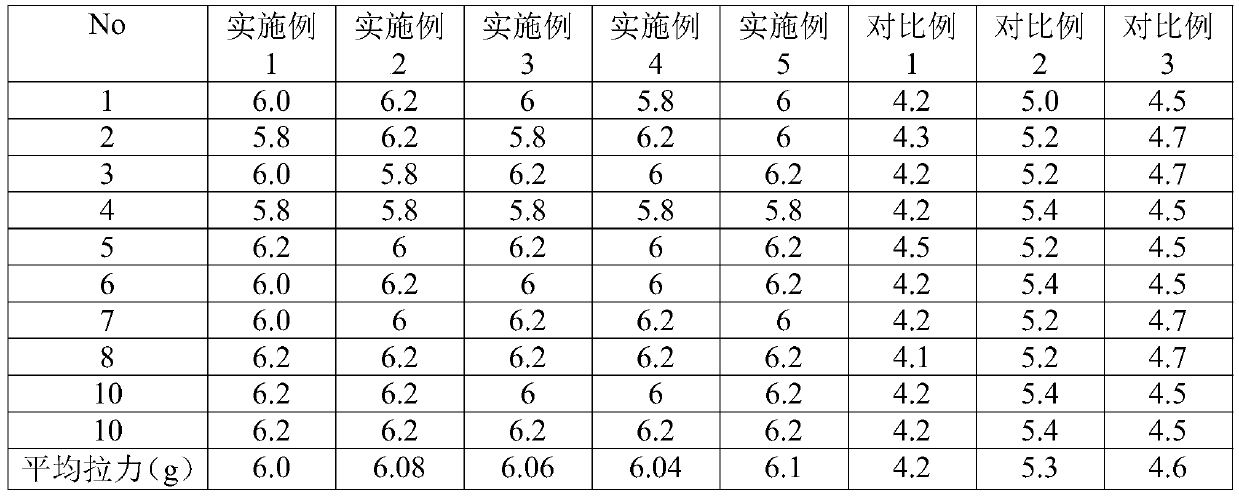

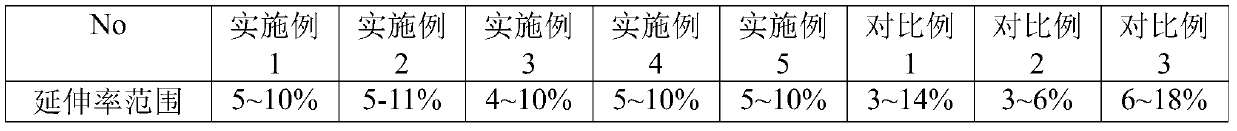

[0030] This embodiment provides a specific implementation of the bonding gold wire, as follows:

[0031] Melting and casting steps: put into the crucible 993g of silver with a purity of 99.99%, 5g of palladium with a purity of 99.99%, 1g of gold with a purity of 99.99%, 1g of copper with a purity of 99.99%, gallium 20PPM, cerium 20PPM, platinum 20PPM, lanthanum 20PPM, After mixing the above components, it is higher than 9.8×10 -4 Melting under Pa vacuum degree, and making alloy bar, the temperature of vacuum melting is 1100 ℃, and the diameter of described alloy bar is 8mm;

[0032] Wire drawing step: drawing the alloy rod to form an alloy wire with a predetermined wire diameter; The alloy wire is obtained by finely drawing it into a fine wire with a diameter of 50 μm;

[0033] Annealing step: annealing the fine wire in a hydrogen-nitrogen mixed gas with a volume ratio of hydrogen and nitrogen of 1:19, the annealing temperature is 500°C, and the annealing speed is 60m / min t...

Embodiment 2

[0035] This embodiment provides a specific implementation of the bonding gold wire, as follows:

[0036] Melting and casting steps: put into the crucible 980g of silver with a purity of 99.99%, 10g of palladium with a purity of 99.99%, 5g of gold with a purity of 99.99%, 5g of copper with a purity of 99.99%, gallium 100PPM, cerium 100PPM, platinum 100PPM, lanthanum 100PPM, The above components are mixed and smelted at a vacuum degree higher than 9.8×10-4Pa, and made into alloy rods, the temperature of vacuum melting is 1200°C, and the diameter of alloy rods is 8mm;

[0037] Wire drawing step: drawing the alloy rod to form an alloy wire with a predetermined wire diameter; The alloy wire is obtained by fine drawing to make a fine wire with a diameter of 20 μm;

[0038] Annealing step: annealing the fine wire in a hydrogen-nitrogen mixed gas with a volume ratio of hydrogen and nitrogen of 1:19, the annealing temperature is 450°C, and the annealing speed is 55m / min to obtain the...

Embodiment 3

[0040] This embodiment provides a specific implementation of the bonding gold wire, as follows:

[0041] Melting and casting steps: 950g of silver with a purity of 99.99%, 30g of palladium with a purity of 99.99%, 10g of gold with a purity of 99.99%, 10g of copper with a purity of 99.99%, gallium 120PPM, cerium 120PPM, platinum 120PPM, lanthanum 120PPM, After mixing the above components, it is higher than 9.8×10 -4Melting under vacuum degree of Pa, and made into alloy rods, the temperature of vacuum melting is 1150℃, and the diameter of alloy rods is 8mm;

[0042] Wire drawing step: drawing the alloy rod to form an alloy wire with a predetermined wire diameter; The alloy wire is obtained by fine drawing to make a micro-fine wire with a diameter of 23 μm;

[0043] Annealing step: annealing the fine wire in a hydrogen-nitrogen mixed gas with a volume ratio of hydrogen and nitrogen of 1:19, the annealing temperature is 500°C, and the annealing speed is 60m / min to obtain the bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com