Guide roller and method for manufacturing optical fiber

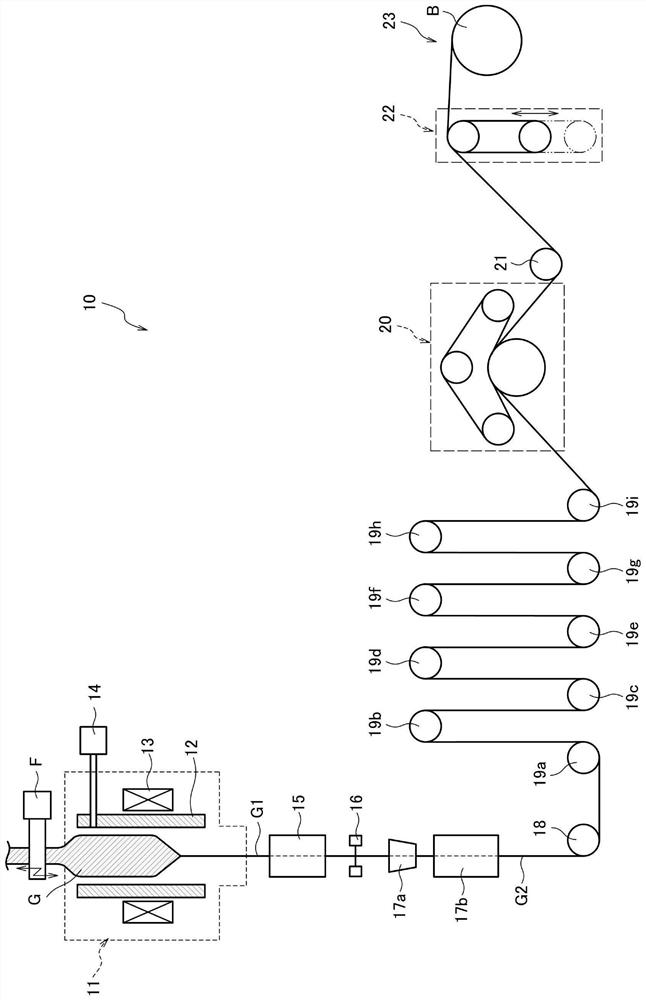

A manufacturing method and technology of guide rollers, which are applied in the field of guide rollers and optical fiber manufacturing, can solve problems such as increased rotation resistance, and achieve the effect of reducing the frequency of disconnection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] [Description of Embodiments of the Present Invention]

[0014] First, the contents of the embodiments of the present invention will be described.

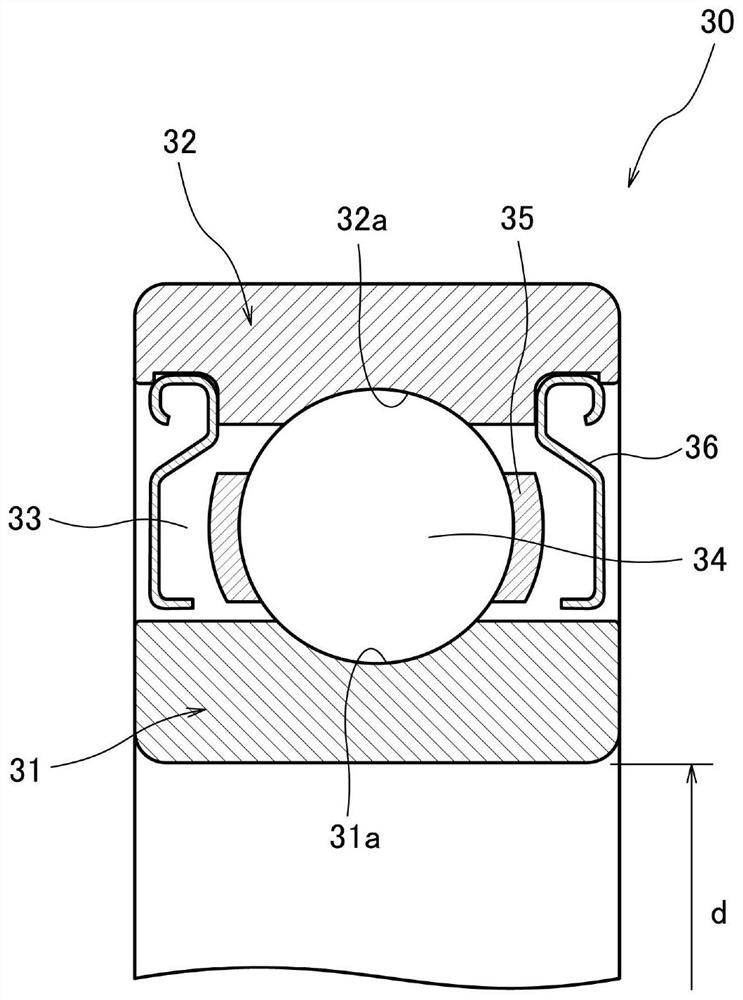

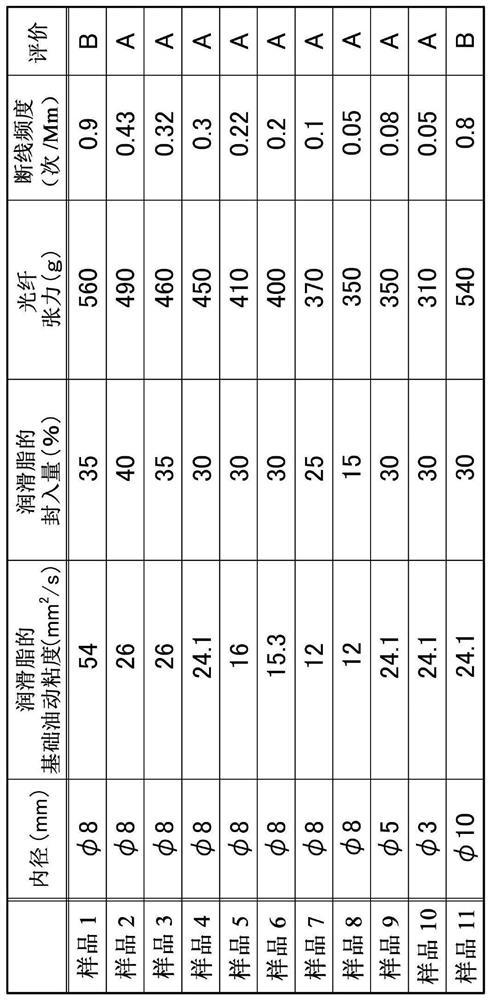

[0015] The guide roller according to the present invention is (1) a guide roller used in the manufacturing process of an optical fiber to guide a traveling optical fiber. Rolling elements rolling in the inner space of the bearing between the inner ring and the outer ring, the base oil dynamic viscosity of the grease sealed in the inner space of the bearing is 26mm at 40°C 2 / s below.

[0016] Set the base oil dynamic viscosity of the grease used in the bearing to 26mm at 40°C 2 / s or less, even when steel balls and grease are used, the rotational resistance of the roller can be reduced compared to a guide roller using grease with a base oil dynamic viscosity of the level used in ordinary bearings . Therefore, the frequency of disconnection of the optical fiber in the manufacturing process of the optical fiber can be redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com