Method for manufacturing composite material of metal/ceramic layer structure

A composite material and manufacturing method technology, applied in the direction of metal layered products, ceramic layered products, chemical instruments and methods, etc., can solve the problems of large difference in thermal expansion coefficient, inability to integrally form layered composite materials, and application of structural materials, etc. Achieve huge economic significance and social benefits, excellent comprehensive performance, and wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method of the invention is used to manufacture composite material plates.

[0033] 1. Preparation of bonding alloy: 3 components of bonding alloy are designed as: Fe, 5%; Ti, 3%; Zn, 10%; Al,

[0034] The balance; the melting point of the high melting point phase is 860°C; the melting point of the low melting point phase is 420°C, and the ratio of solid and liquid phases is 7:3; the preparation method is: put 82% of the total mass of the alloy (the same below) into aluminum Heat to 840°C in a dry pot, add 10% Zn by the total mass of the alloy after the aluminum is melted, and stir to dissolve as a whole; then add 5% Fe and 3% Ti by the total mass of the alloy in turn, dissolve while stirring, and cool down after the dissolution is complete Instantly.

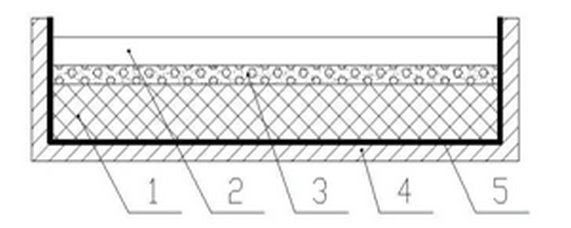

[0035] 2. Prepare the composite material: prepare by tooling method: use tooling mold 4 to realize the reaction of bonding alloy 3 and ceramic plate 1 (see Picture 1-1 ). The specific parameters are: ceramic plate ...

Embodiment 2

[0038] The method of the invention is used to manufacture composite material plates.

[0039] 1. Preparation of bonding alloy: The 3 components of the bonding alloy are designed as follows: Fe, 5.5%; Ti, 3%; Zn, 9.5%; Al, the balance; the melting point of the high melting point phase is designed to be 880°C; ℃, the proportion fraction of solid-liquid two-phase is 8:2, all the other are the same as embodiment 1;

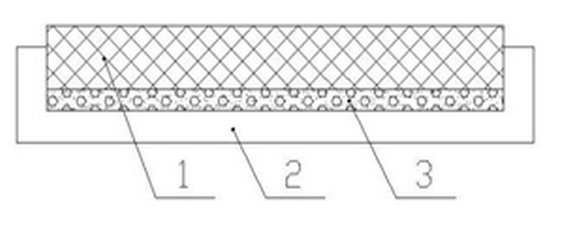

[0040] 2. Composite material preparation: use the shape characteristics of the composite material to prepare, that is, use the shape of the metal plate 2 to process it into a "tooling mold" 4, and apply a thin layer of high-temperature-resistant inorganic coating 5, and then make the bonding Alloy 3 is reacted with metal plate 2, and bonding alloy 3 is reacted with ceramic plate 1 (see Figure 1-2 ). The bonding alloy 3 is 2.5mm thick.

[0041] The composite molding process is as follows: the inner and outer walls of the metal plate 2 are coated with high-temperatu...

Embodiment 3

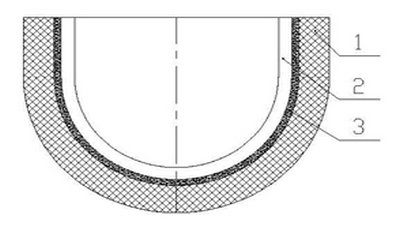

[0043] Adopt the inventive method to manufacture composite casing (referring to figure 2 ).

[0044] 1. Preparation of bonding alloy: The 3 components of the bonding alloy are designed as follows: Ti, 2%; Zn, 13%; Al, the balance; the melting point of the high melting point phase is 730°C, the melting point of the low melting point phase is 420°C, and the ratio of solid and liquid phases The score is preferably 6:4. The preparation method is as follows: put 88% aluminum of the total mass of the alloy into a dry pot and heat it to 800°C, add 10% Zn after the aluminum is melted, stir and dissolve as one; then add 2% Ti, dissolve while stirring, wait for the dissolution When complete, let it cool down.

[0045] 2. Preparation of composite casing: the specific parameters are: ceramic tube 1 size: Φ130*7*1500mm; steel pipe 2 size: Φ112*2*1500mm; bonding alloy 3 composition: Ti, 2%; Zn, 13% ; Al, the balance, the thickness of the bonding alloy layer is 2.2mm.

[0046] The c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com