Device convenient for shunting bonding alloy wire reel and using method thereof

A technology for bonding wire and wire reels, applied in packaging and other directions, can solve the problems of limited number of bonding wire reels, large workload of workers, low production efficiency, etc., so as to reduce production costs, avoid potential safety hazards, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

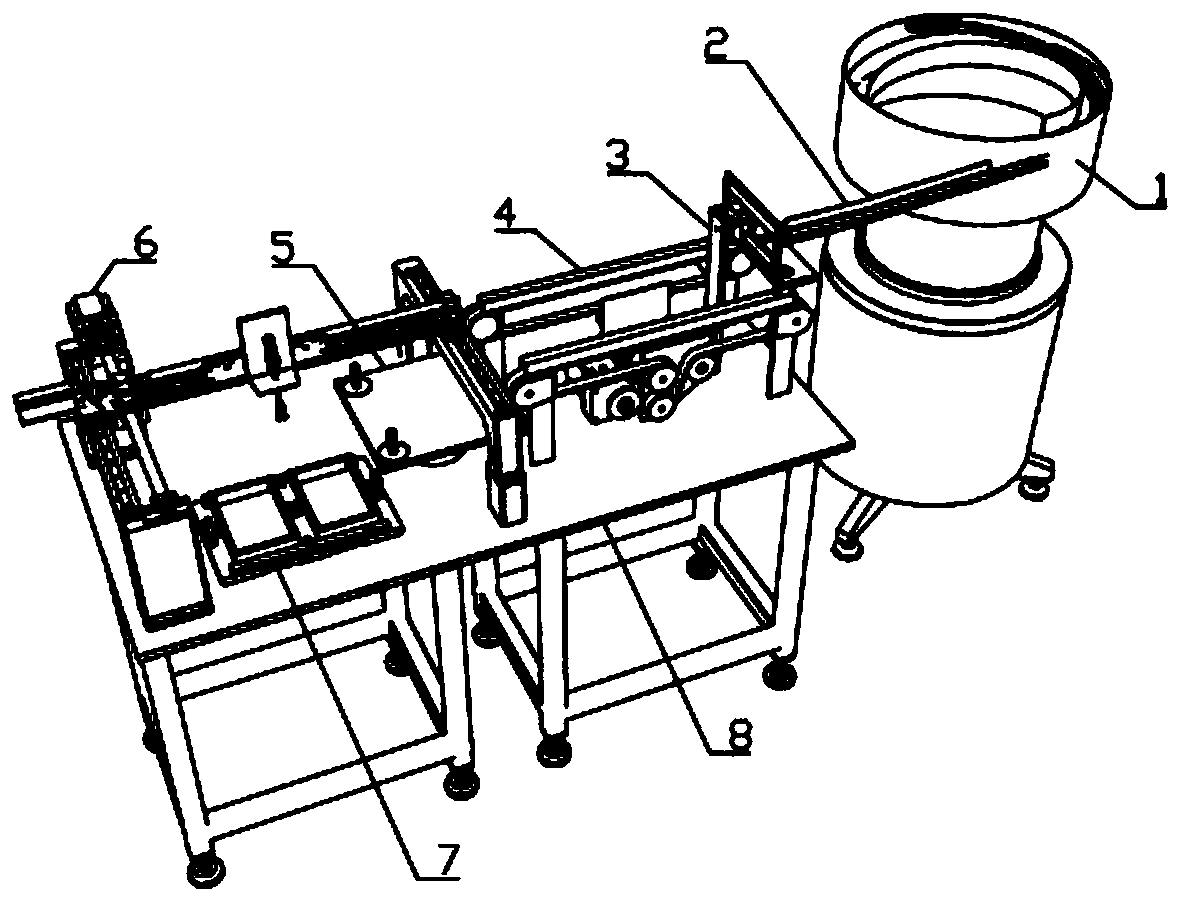

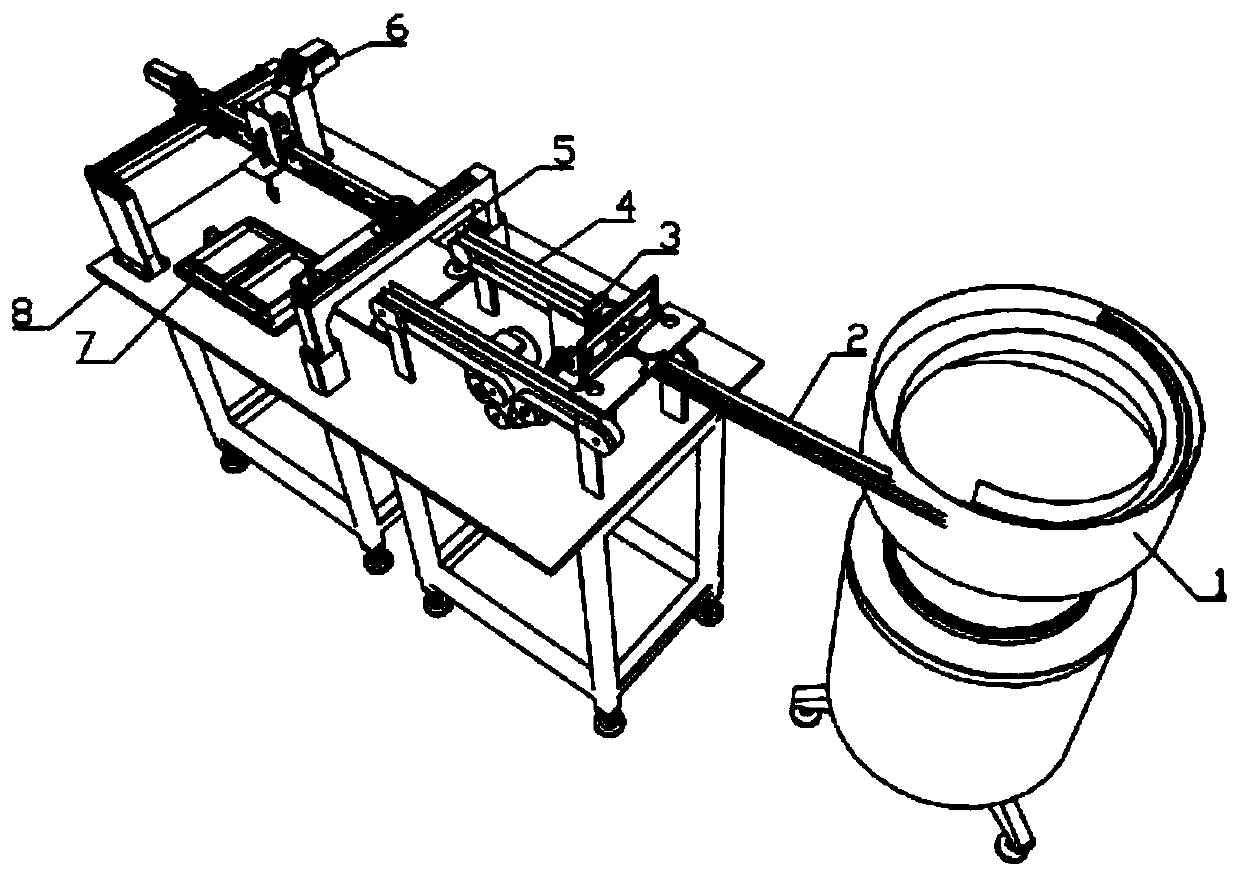

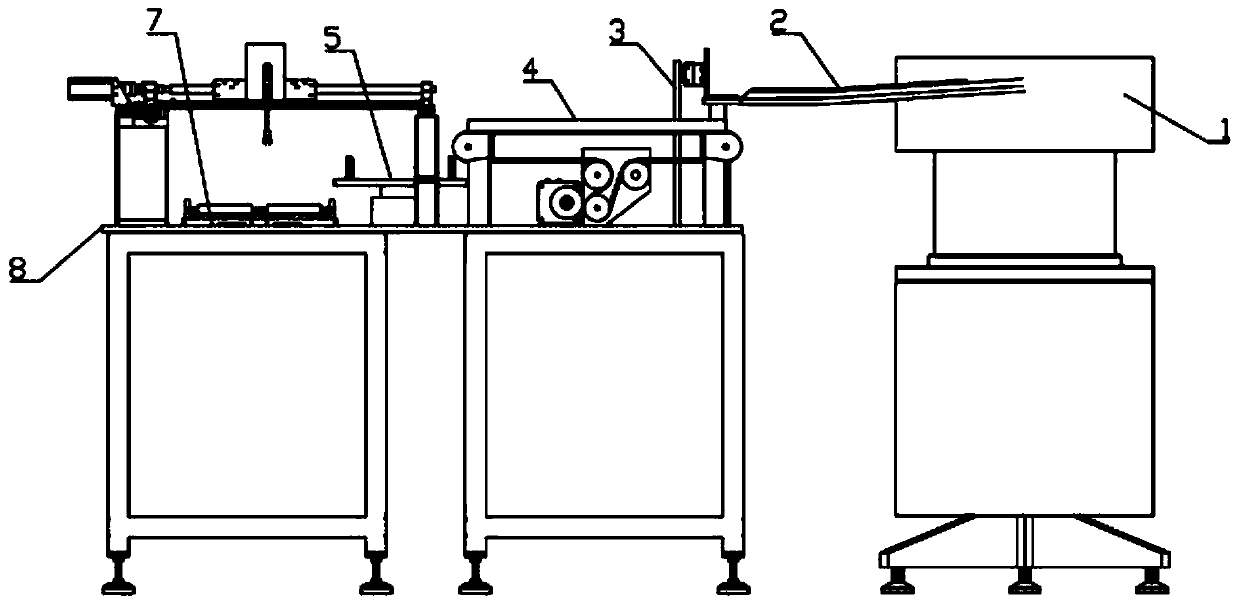

[0050] Such as Figure 1-Figure 12 As shown, the device for facilitating the shunting of bonded gold wire reels of the present invention includes a vibrating feeding mechanism 1, a feeding channel 2, a shunting mechanism 3, a dual-channel conveying mechanism 4, a position exchange mechanism 5, a three-dimensional three-dimensional feeding mechanism 6, and a packing Mechanism 7 and supporting mechanism 8;

[0051] The vibrating feeding mechanism 1 is a vibrating plate, and the outlet of the vibrating feeding mechanism 1 is connected with the inlet of the feeding channel 2;

[0052] The diverter mechanism 3 includes a diverter vertical plate 30, a first motor 31, a zigzag frame 32, an upper rack 33, a lower rack 34, a paddle 35, a diverter ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com