Permanent magnetic force based waterproof rubber strip

A waterproof rubber strip and permanent magnet technology, applied in the direction of permanent magnets, magnets, magnetic objects, etc., can solve the problems of cumbersome installation and disassembly, poor waterproof effect, and left traces, etc., and achieve light weight, no dust and noise, Increase or decrease the effect of magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

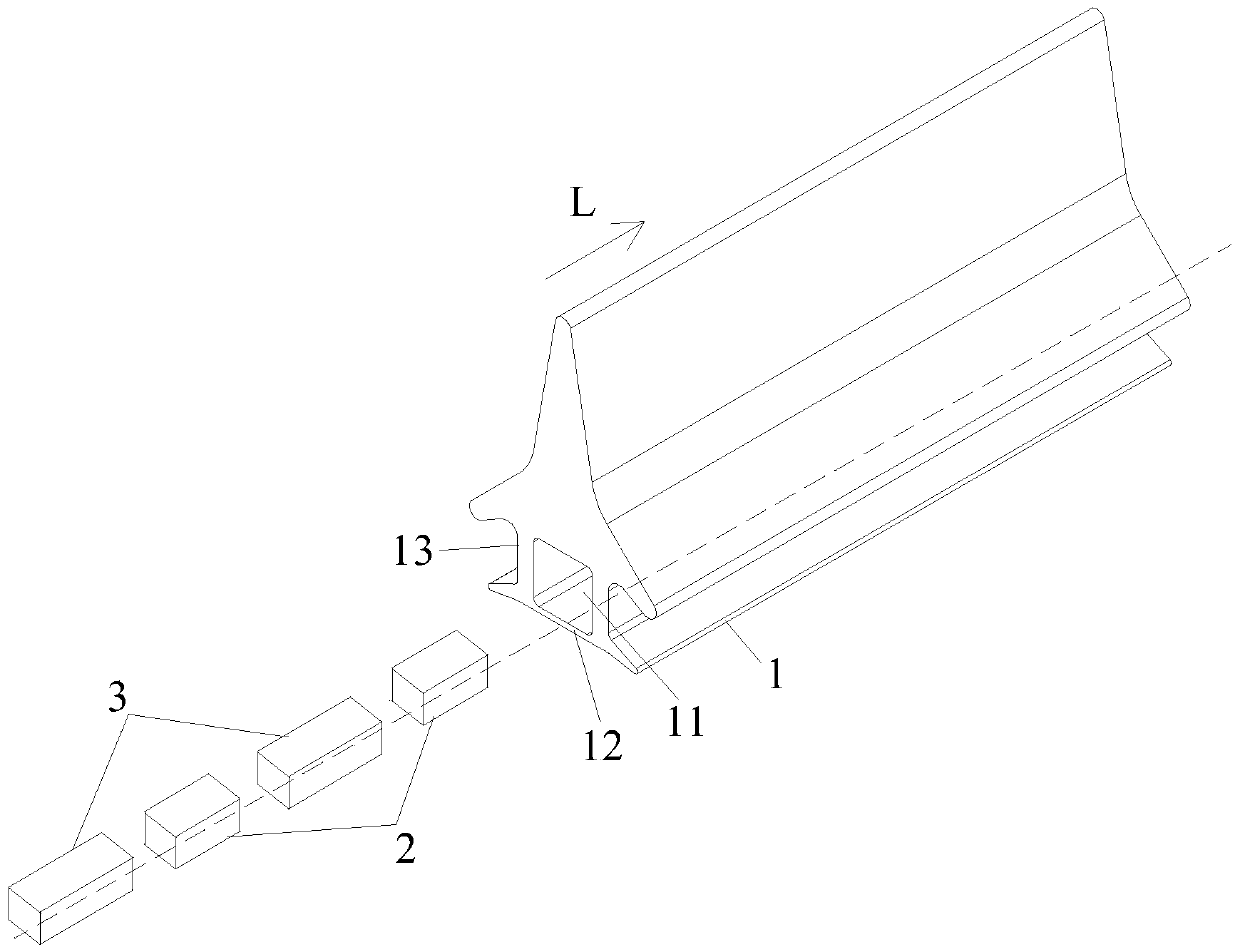

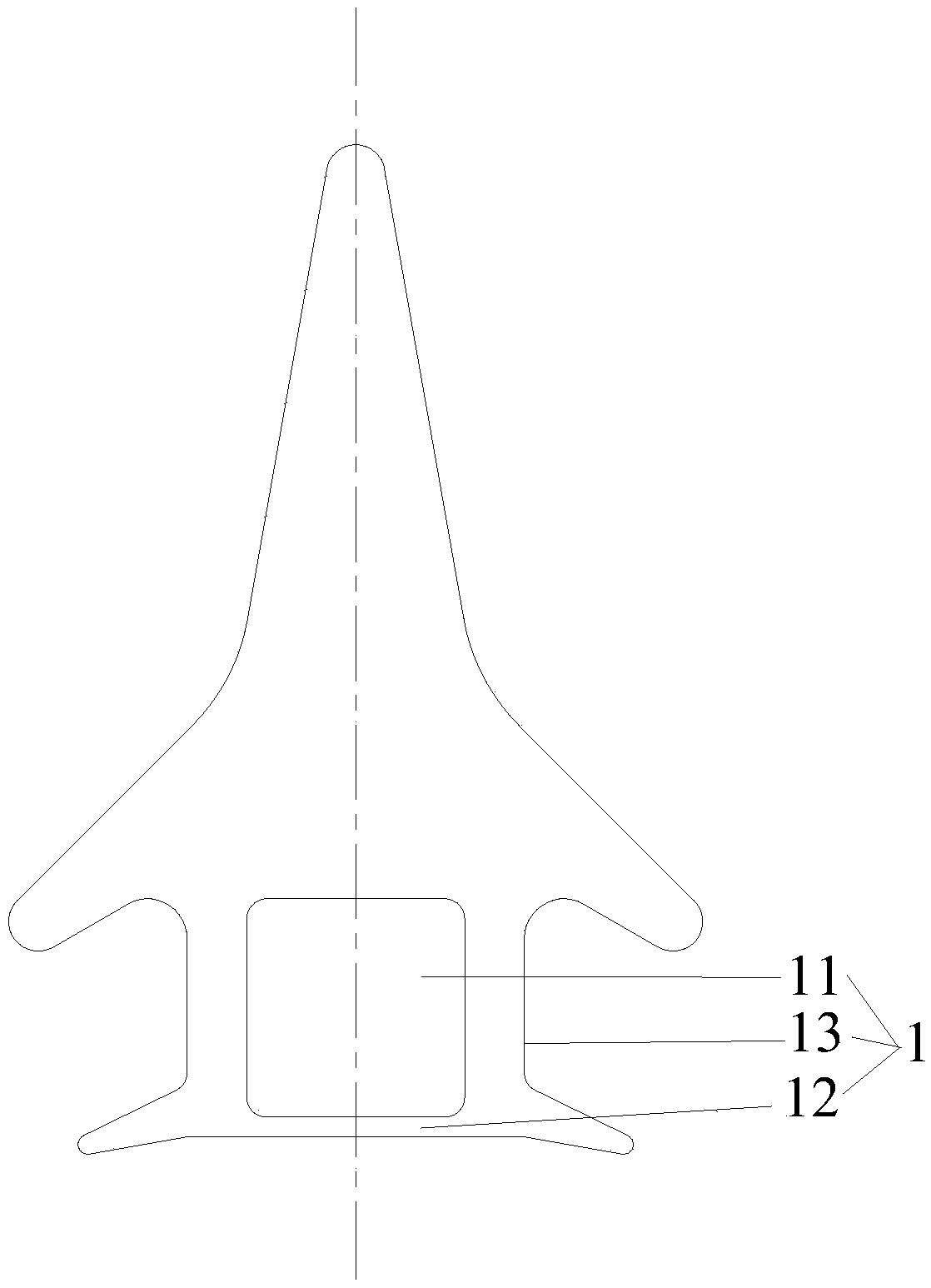

[0031] like figure 1 and figure 2 The permanent magnetic waterproof rubber strip of the illustrated embodiment includes a strip body 1 , a NdFeB permanent magnetic core 2 and a magnetic core spacer rubber strip 3 . The bottom end of the rubber strip body is provided with a magnetic core installation hole 11 , and the magnetic core installation hole 11 extends along the length direction L of the rubber strip body and runs through the entire rubber strip body 1 . The bottom edge 12 of the waterproof rubber strip is formed between the magnetic core installation hole 11 and the bottom surface of the rubber strip body. The bottom edge 12 of the waterproof rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com