Imitation gold bonding alloy wire and preparation method thereof

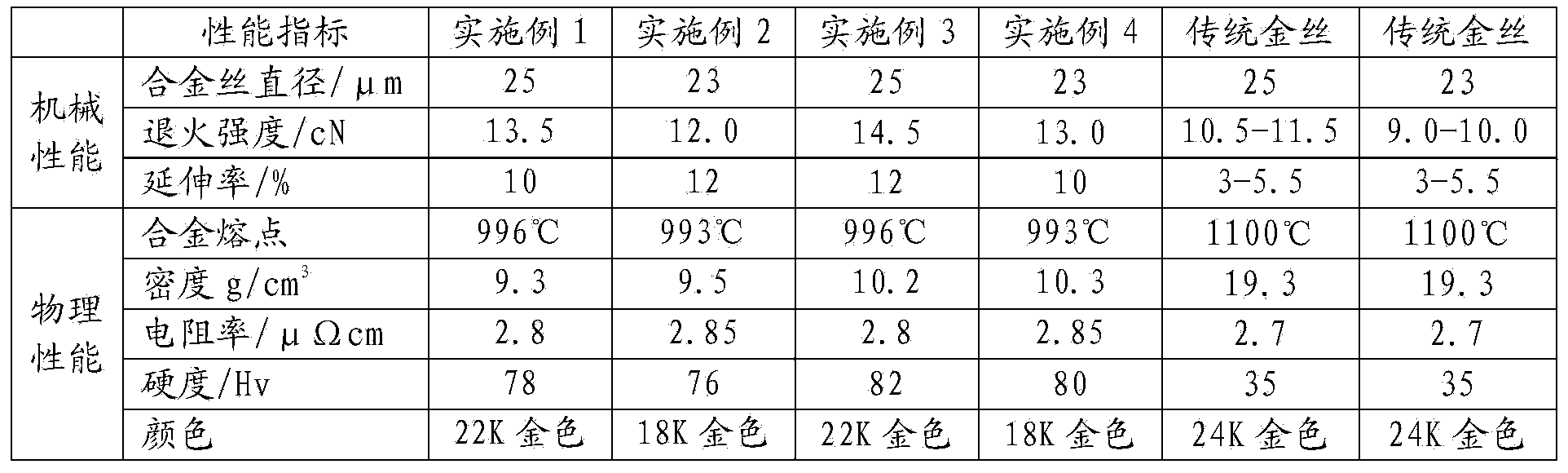

An alloy wire and bonding technology, used in semiconductor/solid-state device parts, electrical solid-state devices, semiconductor devices, etc., can solve the problem of difficulty in further reducing costs, achieve excellent physical and mechanical properties, low raw material costs, Consistent color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare bonding alloy wire as follows:

[0042] (1) Step of smelting the base material: add the base material in the following weight percentages into the crucible: 65% silver, 32% copper, 2% indium, and 1% palladium; % silver Ag: 650g, copper Cu with a purity of 99.99%: 320g, indium In with a purity of 99.5%: 20g, palladium Pd with a purity of 99.9%: 10g.

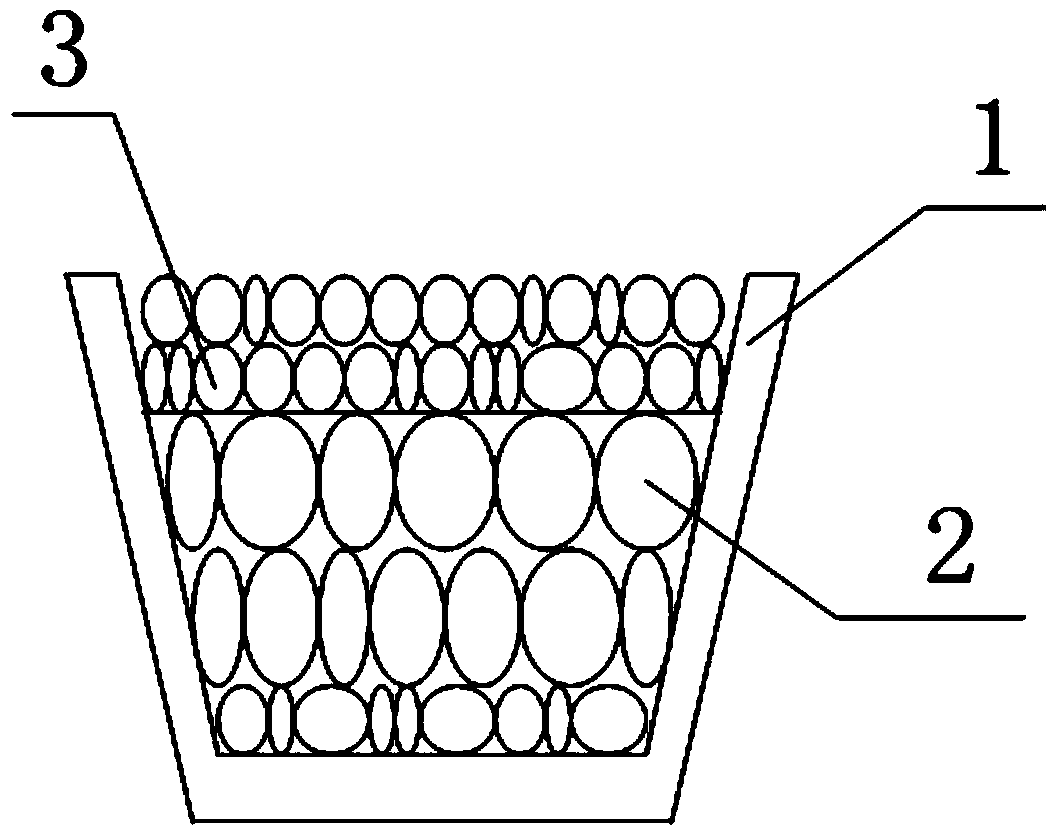

[0043] Put the above base material in a high-frequency furnace. In order to remove oxides, place activated carbon with a purity >99% in the base material to ensure that the activated carbon covers the entire surface of the base material to isolate the base material from contact with air (activated carbon at high temperature , undergoes a displacement reaction with metal oxides, generates carbon dioxide, reduces pure metals, and can remove metal oxides present in raw materials), specifically as figure 1 As shown, the base material 2 is placed in the porcelain crucible 1, and the surface of the base material is compl...

Embodiment 2

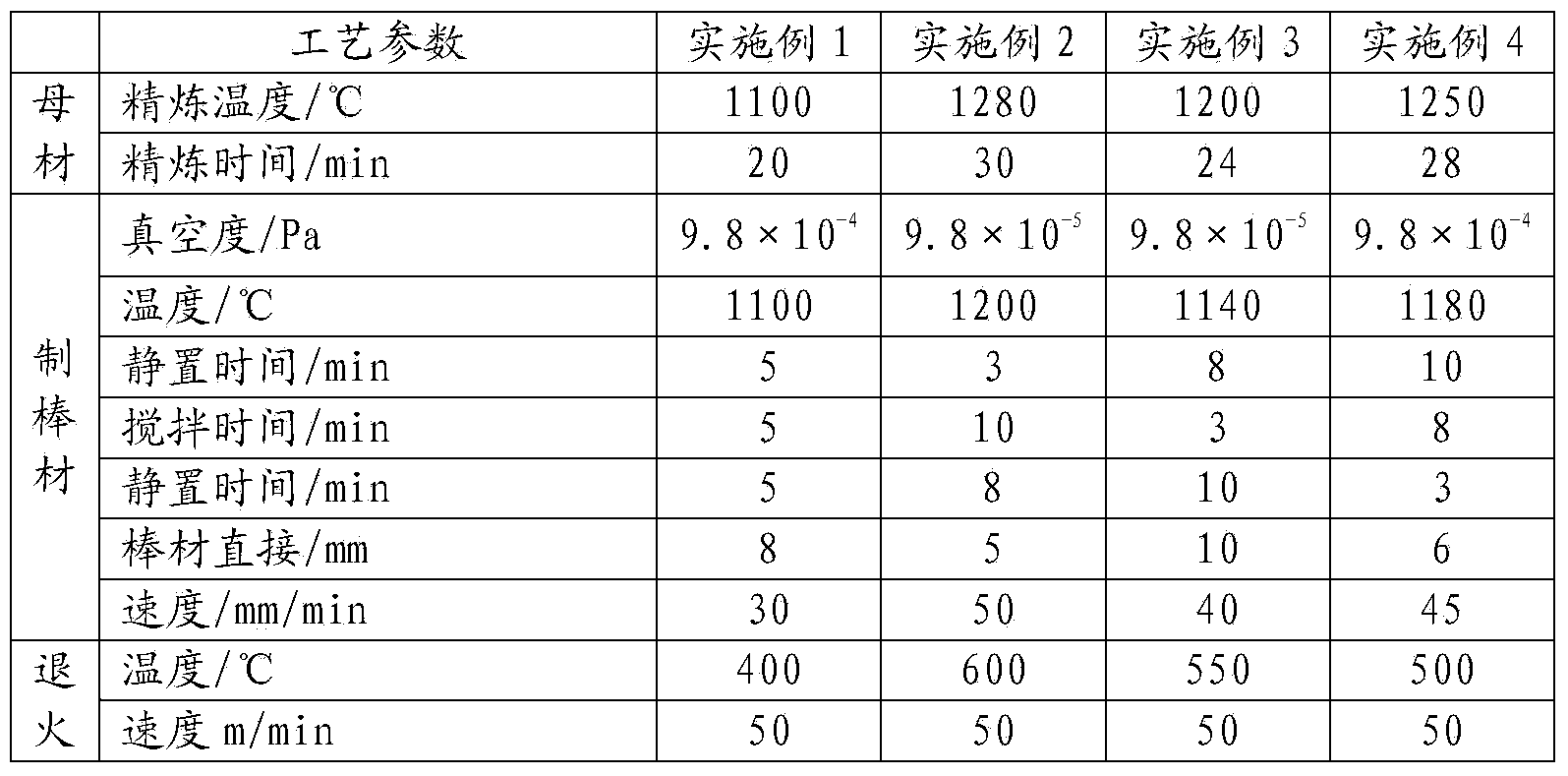

[0053] The preparation steps of this example are basically the same as those of Example 1, and the specific formulation of the base material and the adjustment of processing parameters are shown in Table 1 and Table 2.

[0054] In addition, before the bar making step, the step of "heating→refining→natural cooling" for smelting the base metal is repeated once to further improve the uniformity of the components of the base material.

Embodiment 3

[0056] The preparation steps of this example are basically the same as those of Example 1, and the specific formulation of the base material and the adjustment of processing parameters are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com