Low-cost silver-based bonding alloy wire and preparation method and application thereof

An alloy wire and bonding technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electric solid-state devices, etc., can solve the problem of unstable elongation of Ag-Au-Pd system bonding wire, affecting cost control, and affecting bonding Efficiency and other issues, to achieve the effect of stable and cheap market price, enhanced elongation, and improved oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

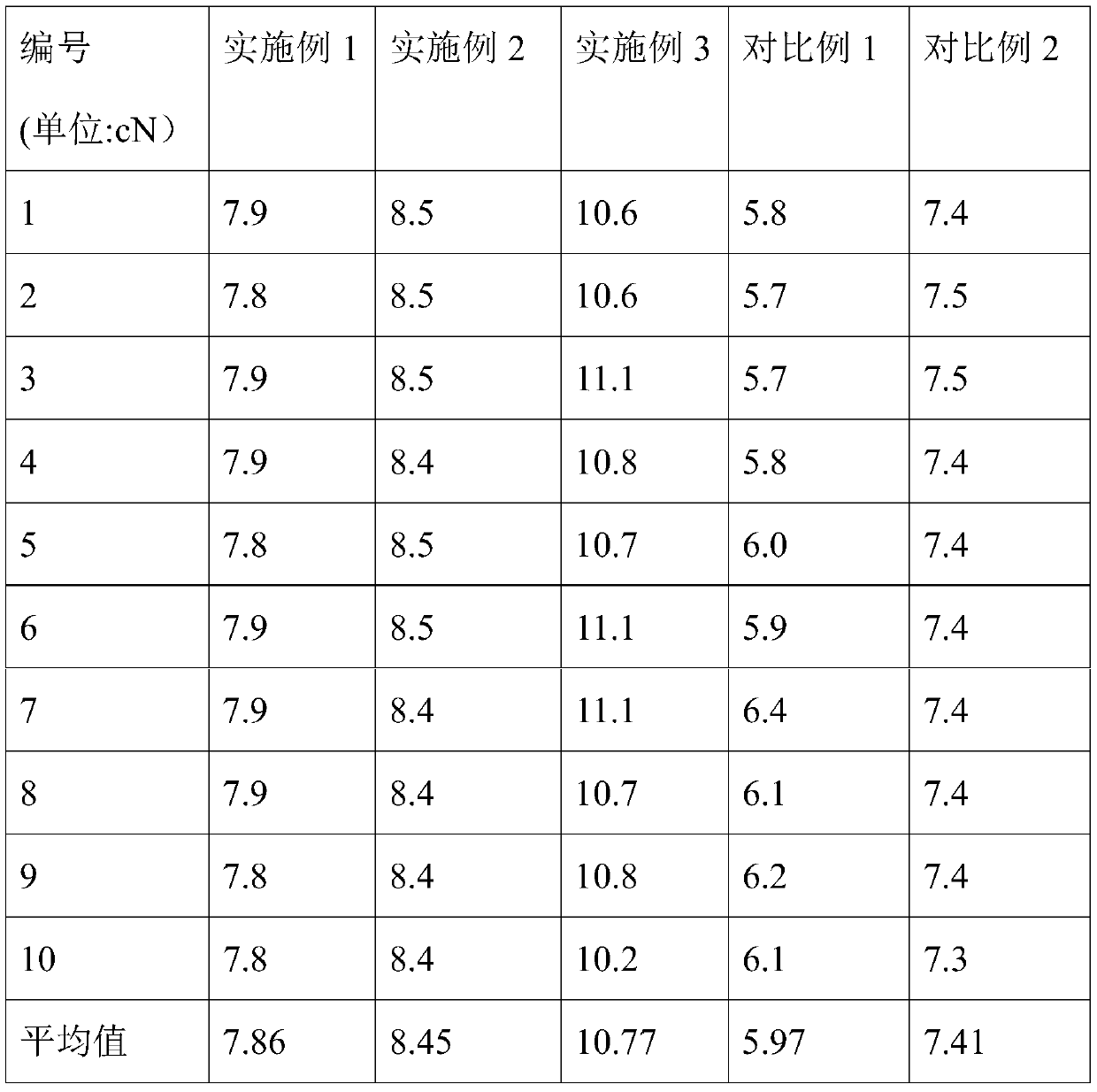

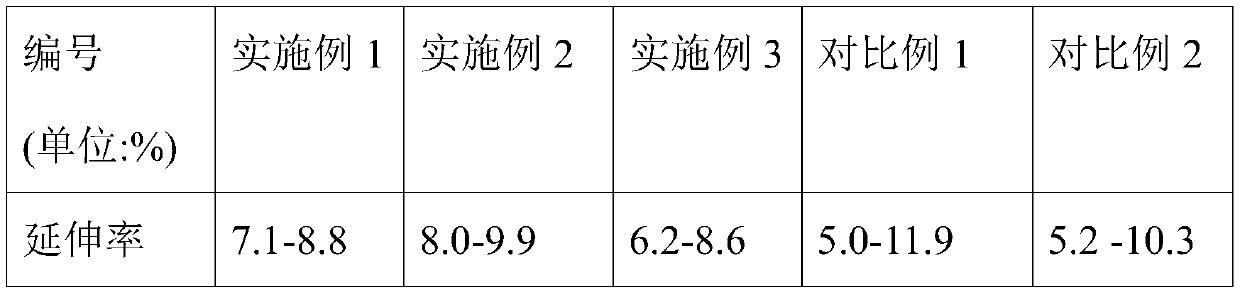

Examples

Embodiment 1

[0023] This embodiment provides a specific implementation of a silver-based bonding alloy wire, as follows:

[0024] (1) Melting and casting: put 995.0g of Ag with a purity of 99.99%, 5.0g of Cu with a purity of 99.99%, and add 40ppm of Pt, 40ppm of Ce, 40ppm of Ti, 40ppm of Ni, and 40ppm of Y, and put them into the crucible together. ×10 -4 Smelting under Pa vacuum degree, the temperature of vacuum smelting is 1100 ℃, then directional and continuous casting to make alloy rods, the diameter of the alloy rods is 8mm;

[0025] (2) wire drawing: the ф8mm rod obtained in step (1) is subjected to rough drawing, middle drawing, fine drawing, and superfine wire drawing processes to obtain a silver alloy wire with a diameter of 20 μm;

[0026] (3) Annealing: the silver alloy wire obtained in step (2) is subjected to annealing heat treatment under the hydrogen-nitrogen mixed protective gas whose volume percentage of hydrogen and nitrogen is 5:95, the annealing temperature is 400°C, an...

Embodiment 2

[0029] This embodiment provides a specific implementation of a silver-based bonding alloy wire, as follows:

[0030] (1) Melting and casting: put 990.0g of Ag with a purity of 99.99%, 10.0g of Cu with a purity of 99.99%, and add Pt80ppm, Ce 80ppm, Ti 80ppm, Ni 80ppm, and Y 80ppm, and put them into the crucible together, and after mixing, it is higher than 9.8 ×10 -4 Smelting under Pa vacuum degree, the temperature of vacuum smelting is 1150 ℃, then directional and continuous casting to make alloy rods, the diameter of the alloy rods is 8mm;

[0031] (2) wire drawing: the ф8mm rod obtained in step (1) is subjected to rough drawing, middle drawing, fine drawing, and superfine wire drawing processes to obtain a silver alloy wire with a diameter of 20 μm;

[0032] (3) Annealing: the silver alloy wire obtained in step (2) is subjected to annealing heat treatment under a hydrogen-nitrogen mixed protective gas with a volume percentage of hydrogen and nitrogen of 5:95, the annealing ...

Embodiment 3

[0035] This embodiment provides a specific implementation of a silver-based bonding alloy wire, as follows:

[0036] (1) Melting and casting: Put 970.0g of Ag with a purity of 99.99%, 30.0g of Cu with a purity of 99.99%, and add 240ppm of Pt, 240ppm of Ce, 240ppm of Ti, 240ppm of Ni, and 240ppm of Y, and put them into the crucible together. ×10 -4 Smelting under Pa vacuum, the temperature of vacuum smelting is 1200°C, and then directional and continuous casting to make alloy rods, the diameter of which is 8mm;

[0037] (2) wire drawing: the ф8mm rod obtained in step (1) is subjected to rough drawing, middle drawing, fine drawing, and superfine wire drawing processes to obtain a silver alloy wire with a diameter of 20 μm;

[0038] (3) Annealing: the silver alloy wire obtained in step (2) is subjected to annealing heat treatment under the hydrogen-nitrogen mixed protective gas whose volume percentage of hydrogen and nitrogen is 5:95, the annealing temperature is 500°C, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com