A bond alloy wire and a preparation method thereof

A technology for bonding wire and alloy, applied in the field of bonding wire and its preparation, can solve the problems of integrated circuit damage and open circuit, achieve the effect of good connection and ensure service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

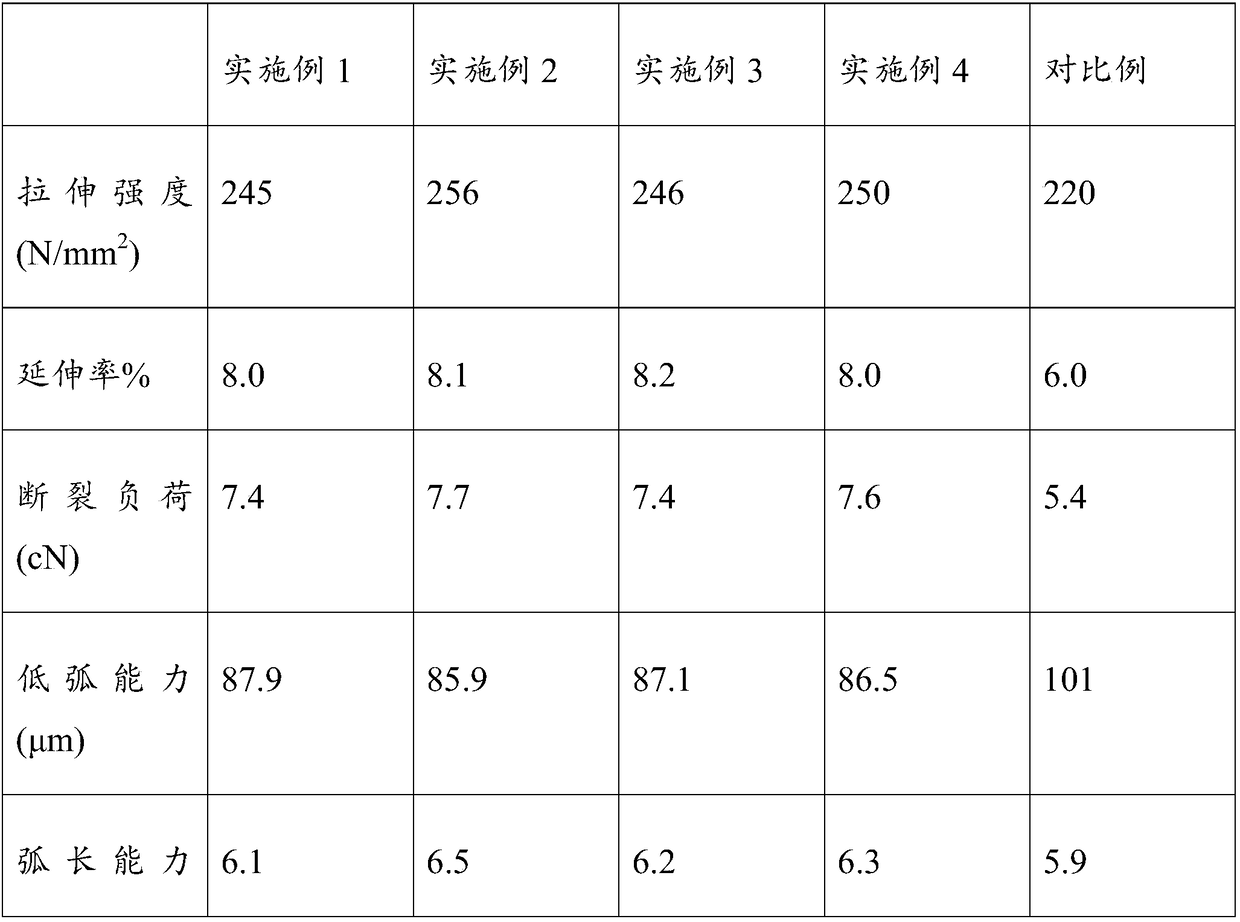

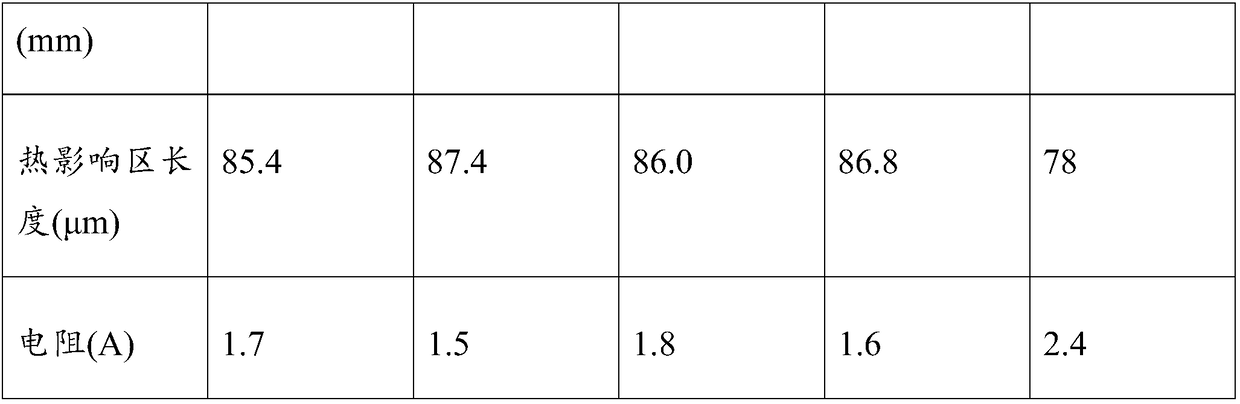

Examples

preparation example Construction

[0026] The preparation process of the bonding wire includes the following steps:

[0027] 1) Using an electric arc furnace, put the gold and pure copper in the above-mentioned mass percentages into the electric arc furnace, use argon gas protection, melt the gold and copper at 1200 ° C, fully stir, and turn off the heating in the state of protective gas. system, let it cool naturally, and make it into a copper-gold alloy after solidification;

[0028] 2) Using an electric arc furnace, put the gold and pure copper in the electric arc furnace according to the above mass percentages, and use argon protection. At 1200 ° C, the gold and palladium are melted. After fully stirring, under the protective gas state, turn off the heating system , let it cool naturally, and make it into a palladium-gold alloy after solidification;

[0029] 3) Put the above-mentioned copper-gold alloy and palladium-gold alloy into an electric arc furnace, use argon protection, melt the alloy at 1200 ° C, ...

Embodiment 1

[0035] The bonding wire of this embodiment includes the following components by mass percentage: gold 99%, copper 0.55%, palladium 0.44%, silver 0.0012%, nickel 0.0006%, bismuth 0.0015%, beryllium 0.0005%, cerium 0.0005%, zinc 0.001% , magnesium 0.001%, calcium 0.002%, aluminum 0.0008%, lead 0.0009%.

[0036] The preparation process of the bonding wire includes the following steps:

[0037] 1) Using an electric arc furnace, put the gold and pure copper in the above-mentioned mass percentages into the electric arc furnace, use argon gas protection, melt the gold and copper at 1200 ° C, fully stir, and turn off the heating in the state of protective gas. system, let it cool naturally, and make it into a copper-gold alloy after solidification;

[0038] 2) Using an electric arc furnace, put the gold and pure copper in the electric arc furnace according to the above mass percentages, and use argon protection. At 1200 ° C, the gold and palladium are melted. After fully stirring, un...

Embodiment 2

[0045] The invention discloses a bonding alloy wire, comprising the following components by mass percentage: gold 99.5%, copper 0.300%, palladium 0.190%, silver 0.001%, nickel 0.0005%, bismuth 0.0005%, beryllium 0.0005%, cerium 0.0008%, zinc 0.003%, magnesium 0.002%, calcium 0.0005%, aluminum 0.0002%, lead 0.001%.

[0046] The preparation method of the bonding wire in this embodiment is the same as that in Embodiment 1, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com