Hard alloy transverse bearing body for spiral drilling rig and production method thereof

A cemented carbide, radial bearing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as inability to meet requirements, increase wear resistance time, etc., to change impact strength, speed up cooling speed, reduce The effect of the frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment one: the steps that comprise are as follows:

[0051] a) The step of producing the cemented carbide strip 2; when producing the cemented carbide strip 2, the mass ratio of cobalt powder is 8%, and tantalum and / or niobium rare metals with a mass ratio of 0.2% are added; the rest is tungsten powder ;

[0052] b) the step of making said inner steel body 1;

[0053] c) Steps for making the bushing 5;

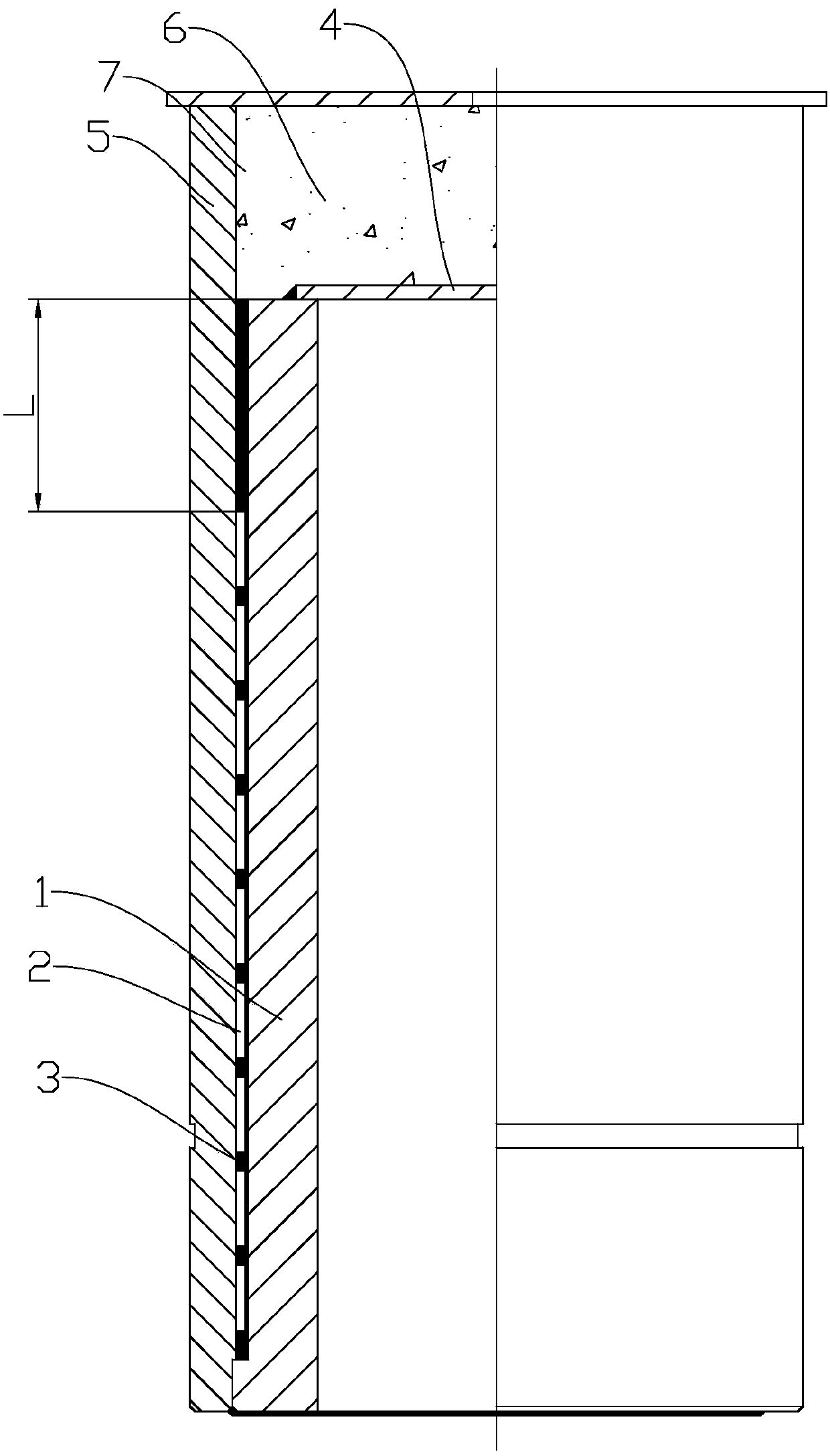

[0054] d) a step of welding the cover plate 4 on the top end of the inner steel body 1;

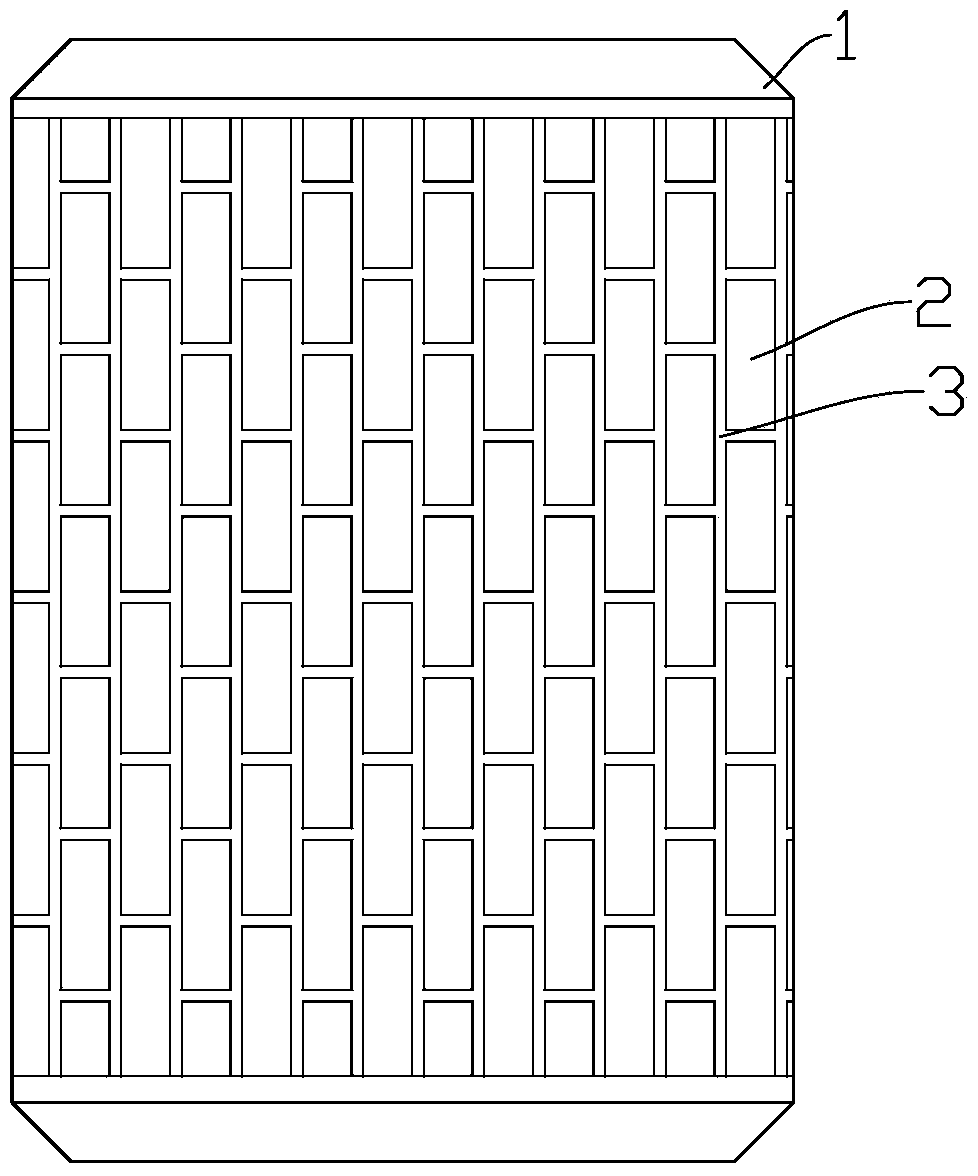

[0055] e) The step of bonding the cemented carbide strips 2 on the surface of the inner steel body 1; gaps are provided between the cemented carbide strips 2;

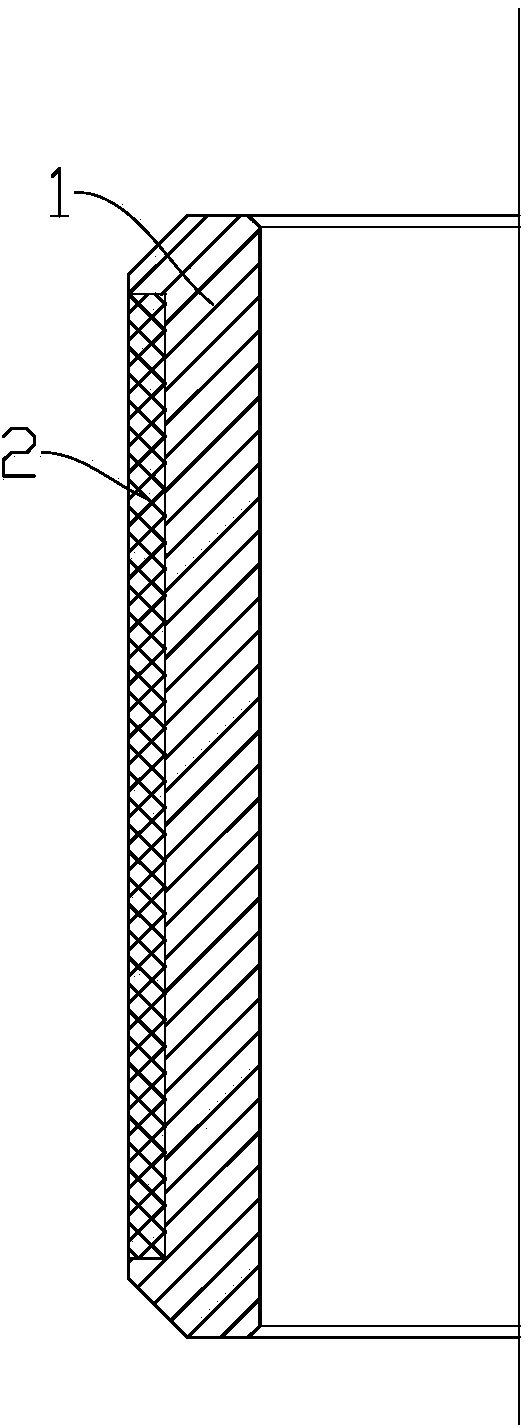

[0056] f) The step of loading the inner steel body 1 with the cover plate 4 welded and the cemented carbide strip 2 bonded into the bushing 5;

[0057] The length L between the top surface of the inner steel body 1 and the uppermost cemented carbide strip 2 is 45mm;

[0058] g) The step of filling the gaps between...

Embodiment 2

[0066] Embodiment two: the steps that comprise are as follows:

[0067] a) The step of producing the cemented carbide strip 2; when producing the cemented carbide strip 2, the mass ratio of cobalt powder is 10%, and tantalum and / or niobium rare metals with a mass ratio of 0.3% are added; the rest is tungsten powder ;

[0068] b) the step of making said inner steel body 1;

[0069] c) Steps for making the bushing 5;

[0070] d) a step of welding the cover plate 4 on the top end of the inner steel body 1;

[0071] e) The step of bonding the cemented carbide strips 2 on the surface of the inner steel body 1; gaps are provided between the cemented carbide strips 2;

[0072] f) The step of loading the inner steel body 1 with the cover plate 4 welded and the cemented carbide strip 2 bonded into the bushing 5;

[0073] The length L between the top surface of the inner steel body 1 and the uppermost cemented carbide strip 2 is 50mm;

[0074] g) The step of filling the gaps betwee...

Embodiment 3

[0082] Embodiment three: the steps that comprise are as follows:

[0083] a) The step of producing the cemented carbide strip 2; when producing the cemented carbide strip 2, the mass ratio of cobalt powder is 8.5%, and tantalum and / or niobium rare metals with a mass ratio of 0.23% are added; the rest is tungsten powder ;The " / " represents the relationship of or;

[0084] b) the step of making said inner steel body 1;

[0085] c) Steps for making the bushing 5;

[0086] d) a step of welding the cover plate 4 on the top end of the inner steel body 1;

[0087] e) The step of bonding the cemented carbide strips 2 on the surface of the inner steel body 1; gaps are provided between the cemented carbide strips 2;

[0088] f) The step of loading the inner steel body 1 with the cover plate 4 welded and the cemented carbide strip 2 bonded into the bushing 5;

[0089] The length L between the top surface of the inner steel body 1 and the uppermost cemented carbide strip 2 is 53mm;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com